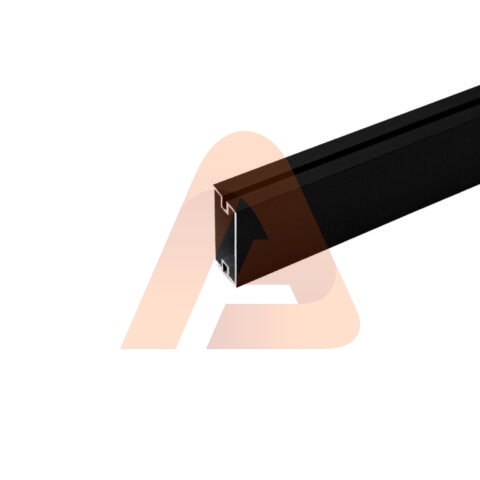

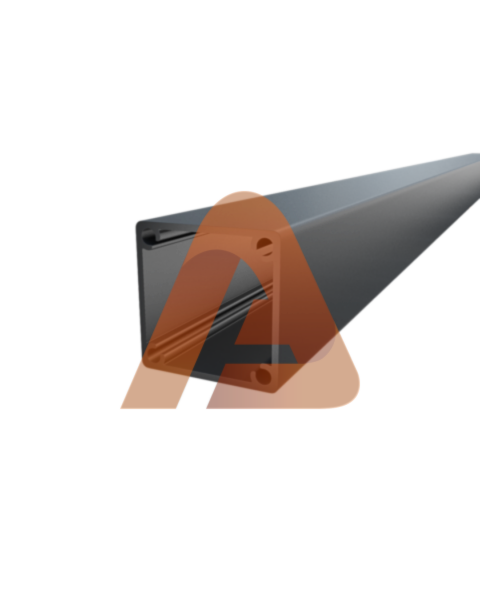

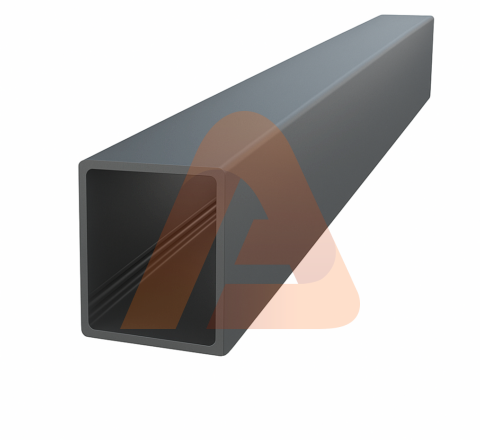

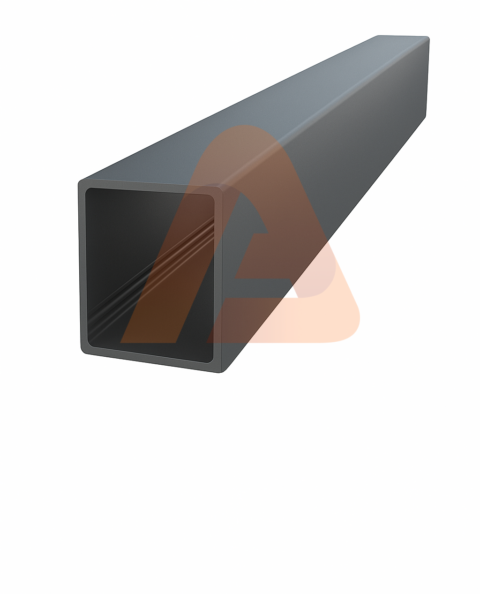

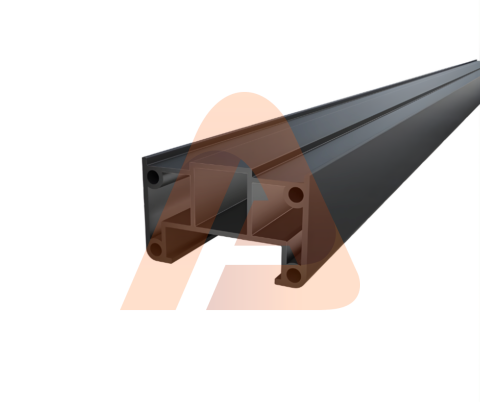

3″ x 8ft HD Post (.125″ Walls)

The 3″ x 8ft heavy-duty aluminum fence post with .125″ wall thickness is the backbone of many modern aluminum fencing systems, valued for its exceptional strength, lightweight design, and lasting protection against corrosion. Designed for both residential and commercial applications, this post combines sleek styling with engineered performance, giving homeowners, contractors, and architects the confidence to build fences that balance beauty with durability. The “.125” wall specification indicates a thicker aluminum profile than standard posts, which means improved structural integrity, increased resistance to bending from wind or gate loads, and longer life in demanding conditions. Whether used as a line post, end post, corner post, or a gate hinge support, this 8-foot tall component brings reliable strength to layouts dealing with variable heights, uneven grades, or heavy gates—all while maintaining a clean, modern aesthetic that complements today’s homes and properties.

Table of Contents

Core Specifications and Material Advantages

When evaluating aluminum fencing components, the 3-inch profile size of this post is a sweet spot between visual elegance and practical load support. Its 8-foot length provides ample room for versatile installations, from low retaining walls to tall privacy enclosures, ensuring that a single component can serve multiple purposes. The .125-inch wall thickness distinguishes it from lighter-weight alternatives by delivering superior rigidity and impact resistance. Made from non-rusting 6063-T6 aluminum, the post naturally resists corrosion—even in coastal or high-moisture environments—without the constant upkeep that wood or steel might require. With powder-coated finishes, these posts retain color and gloss for years, offering extended lifecycle value while minimizing maintenance. Compared to galvanized steel posts, aluminum is lighter to handle, faster to install, and easier to modify on-site, which saves labor while maintaining long-term resilience.

When to Choose Heavy-Duty Over Standard Posts

The decision between a heavy-duty (.125 wall) post and a standard-weight alternative should revolve around performance needs and environmental exposure. For sites exposed to high winds, taller fencing (over 6 feet), or privacy applications with solid panels, heavy-duty posts prevent deflection and sag. Similarly, gate installations—especially double-swing or automated types—benefit from the added wall strength that supports repeated hinge torque and latch impact. In regions with frost heave or dense soil, thicker-wall posts resist deformation when thermal expansion and ground movement occur. Even aesthetically, the robust cross-section creates stronger, cleaner lines that maintain alignment with fewer reinforcements. Homeowners planning for minimal long-term maintenance or those in coastal zones will appreciate the corrosion-proof nature and return on investment that heavy-duty wall construction offers for decades of performance.

Products

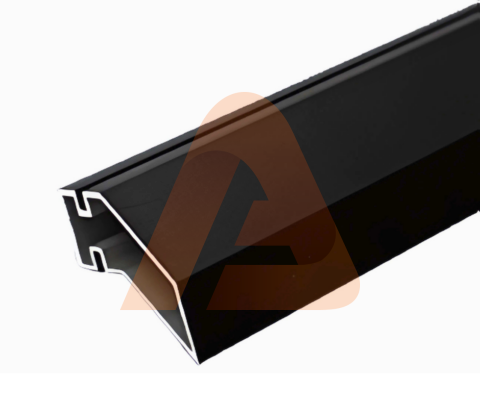

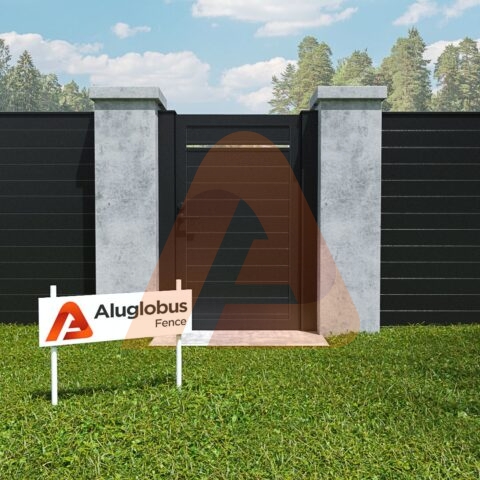

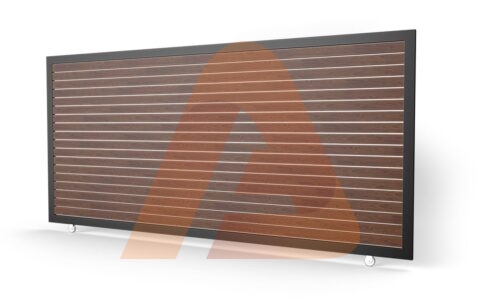

Alu Cladding Clad120 – Woodgrain Teak (Aluminum Cladding Panel)

$157.50Product Profiles

At Aluglobus Fence, our exclusive aluminum fence profiles are designed to offer flexibility, strength, and sleek architectural appeal for any fencing project. From compact and minimal options like ALU15 to more robust and privacy-focused systems such as ALU50 T&G and ALU60, each profile is engineered for long-term outdoor performance. Our lineup also includes hybrid configurations like ALU40+15, giving you the freedom to achieve a modern aesthetic without compromising on privacy or durability. Whether you’re designing for residential, commercial, or custom architectural use, our product profiles deliver refined style and structural integrity backed by professional-grade quality.

Planning Your Layout: Spacing, Roles, and Count

Proper layout planning is the backbone of a professional aluminum fence installation. Before setting the first post, it’s crucial to map out spacing, post roles, terrain conditions, and gate locations to minimize adjustments during the build. Typical post spacing for aluminum systems ranges around 6 to 8 feet center-to-center, though this varies with panel design and local codes. Using the 3″ x 8ft HD post allows more flexibility between supports due to its thicker wall and strength against lateral forces. Start by marking line posts where panels will attach, then identify specialized points for gate hinge posts, corner assemblies, and end terminations. On sloped properties, space adjustments may be necessary to account for angle differences and panel racking limits. Always overestimate your post count slightly to allow for replacements or last-minute design refinements.

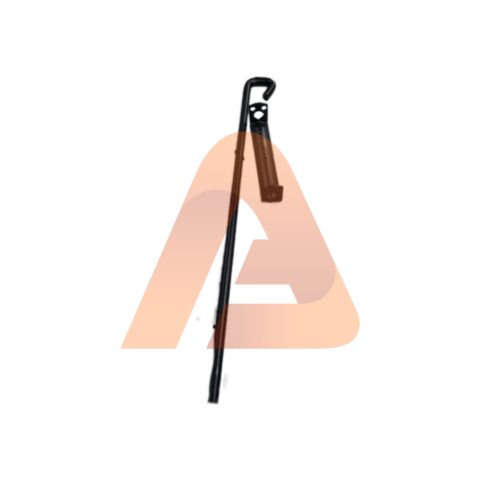

Line vs. End vs. Corner vs. Gate Hinge Posts

Each type of post serves a specific function. Line posts sustain even panel spacing and carry uniform pressure across fence runs, while end posts terminate a section and often anchor stronger brackets. Corner posts handle directional changes and therefore need additional depth and alignment accuracy, as torque from adjoining panels can distort misaligned corners. The gate hinge post, the most critical of the group, bears the ongoing motion stresses of doors. Using a heavy-duty post for hinges ensures the structure doesn’t torsion over time as gate weight and wind pressures combine. Reinforcing the hinge area with gussets or sleeve inserts can further strengthen high-use installations like driveways or pool enclosures.

Wind, Terrain, and Local Codes

Wind exposure directly influences how far apart posts can be placed and what footing depth is needed. Areas designated as high-wind or coastal exposure zones—especially where gusts exceed 80 mph—require deeper concrete embeds and may reduce spacing increments for maximum safety. Terrain plays an equally important role: hillside designs or uneven grades introduce lateral load variances that your post layout must absorb. Always consult local building codes or HOA design rules before excavation, as height limits, setback distances, and finish color requirements can differ. Acquiring necessary permits and HOA documentation early prevents project delays and ensures compliance before material delivery.

Footings and Foundations for .125″ Wall Posts

A strong fence begins underground, and aluminum posts rely on properly sized footings to maintain alignment and load strength. For the 3″ x 8ft heavy-duty aluminum post, the footing diameter and depth depend on post load, frost line, and wind classification, but a general rule is to dig holes twice the post width in diameter and deep enough to reach below frost line or at least 24 inches for standard applications. Always start with a gravel base (around 6 inches) at the bottom of each hole to allow drainage before pouring concrete. Using a concrete mix ratio around 1:2:3 (cement:sand:gravel) yields excellent compressive strength without excessive shrinkage. Posts must remain true-plumb during curing, held by temporary bracing until the concrete sets—usually after 24 to 48 hours depending on temperature. This ensures that the post remains straight under operational and environmental loads.

Popular Individual Profiles

What Our Customers Say

Product Categories

Whether you’re aiming to boost curb appeal, secure your perimeter, or create a stylish outdoor space, our aluminum-based solutions offer unmatched versatility and lasting quality. We provide a range of finishes, styles, and customizable options to suit residential and commercial projects of any scale. Our team is ready to guide you through product selection, layout planning, and installation support to ensure your vision becomes a reality.

Explore our full range of aluminum fencing systems, profiles, hardware, and accessories to find the perfect fit for your project.

In‑Concrete vs. Surface‑Mount Bases

Choosing between in-ground and surface-mount foundations depends primarily on the installation surface and project type. In-concrete installations are best for open soil applications where maximum strength and wind resistance are desired; they secure the post directly in the earth and allow for incremental height adjustment. Surface-mount bases, on the other hand, are ideal for patios, pool decks, or retaining walls where excavation isn’t practical. These mounts attach to concrete slabs using expansion anchors or structural epoxy, locking the post securely in place. When selecting surface-mount options, maintain a minimum setback from slab edges to prevent cracking, and ensure the post base fits the 3″ profile of heavy-duty posts. Checking compatibility with sleeve inserts or welded plate systems helps maintain uniform appearance and performance between mixed-mount fencing sections.

Drainage, Corrosion Prevention, and Longevity

One of the advantages of aluminum is its inherent resistance to rust, but maintaining proper drainage further ensures longevity. For in-ground posts, always allow weep paths or gravel sleeves so trapped moisture can dissipate, preventing freeze-thaw stresses. Where aluminum meets dissimilar metals (e.g., steel anchors or concrete rebar), isolate contact using nylon or rubber gaskets to avoid galvanic corrosion. Touch-up paints matching the powder coat finish can be applied at cut points or scratches to seal exposed aluminum. In coastal environments, routine rinsing to remove salt spray every few months keeps surfaces flawless. Including these preventive steps guarantees that .125″ wall posts maintain their structural and visual performance for the long term, even under challenging environmental cycles.

Panel and Accessory Compatibility

The 3″ x 8ft HD aluminum posts pair seamlessly with most modern aluminum fence panels designed for modular systems. Their internal spacing and external profile align perfectly with standard bracket kits, U-channels, and decorative post caps that enhance the finished look. The tighter tolerances of the .125″ wall make them compatible with both framed panels and louver-style inserts, resisting deflection under lateral tension. Whatever manufacturer you choose, verify that your bracket alignment and hole pattern correspond to the 3″ specification for trouble-free assembly. This ensures hassle-free installation and precise fitment for accessories like lighting caps, finials, and ornamental trims that complete the project’s architectural presentation.

Popular Products

Cost, Value, and Project Scenarios

Understanding how the 3″ x 8ft HD post fits your budget requires balancing upfront cost against lifecycle savings. Although heavier-duty posts cost more per unit, they reduce replacement frequency and offer added safety margins for larger or higher fences. For a 100-foot project using 6-foot panels, you might need roughly **18 posts—**but using heavy-duty posts at stress points (like corners and gates) while mixing standard posts for line sections optimizes both cost and performance. Long-term savings arise from their corrosion-proof nature, eliminating repainting or replacement cycles that plague wood or iron systems. In return, they preserve architectural appeal and structural integrity for decades—especially in areas subject to extreme weather or moisture.

Choosing the Right Quantity and Add‑Ons

While selecting your post quantity, account for end, line, and corner configurations, and remember that double-swing gates need two hinge posts. Accessories such as decorative caps, brackets, and fasteners can enhance durability and style, while surface-mount bases, shims, and touch-up kits support varying terrains and finishes. Each 3″ post integrates cleanly with adjustable bracket kits designed for modular fencing, allowing flexibility in direction changes or slopes. Planning every accessory in advance ensures visual consistency and eliminates downtime waiting on extra hardware shipments, saving both time and labor during installation.

Warranty, Care, and Maintenance Rhythm

Most premium aluminum fence posts include generous manufacturer warranties that protect against structural failure and coating defects. However, maintenance remains key to keeping your investment looking new. A seasonal rinse with mild soap and water removes dirt, pollen, or salt, restoring the metallic sheen. Inspect cap seals, hinge bolts, and corner joints for wear or loosening twice yearly, tightening hardware as needed. In fall and spring, check footing integrity for freeze-thaw shifts—especially in areas with clay soils. Following this consistent rhythm not only prolongs your fence’s aesthetic value but also fulfills warranty conditions over the structure’s lifetime.

Popular Products

Alu Cladding Clad120 – Woodgrain Teak (Aluminum Cladding Panel)

$157.50Buying Checklist and Next Steps

Before purchase, confirm fence height, panel compatibility, gate widths, and weight. Review layout drawings to ensure accurate footing spacing and mark known terrain shifts or windy exposures for appropriate reinforcement. Check your local code or HOA for approved fence heights and setbacks before placing orders. Once verified, visit 3″ x 8ft HD post .125 walls shop page to order the heavy-duty posts directly and explore compatible accessories and installation materials for a complete system build.

Projects

Frequently Asked Questions

What makes the 3″ x 8ft HD aluminum fence post different from a standard post?

The 3″ x 8ft HD aluminum post features a .125″ wall thickness, which is heavier and stronger than standard posts. This increased thickness provides superior resistance against bending, warping, and wind stress, making it ideal for tall fences, gate supports, and high-exposure areas.

Can this heavy-duty post be used for both residential and commercial fences?

Yes. The heavy-duty construction and sleek 3″ profile make it versatile for both residential applications such as privacy or pool fencing, and commercial uses like perimeter or security enclosures. Its strength, durability, and corrosion resistance ensure long-term reliability in all environments.

How deep should the 3″ x 8ft aluminum post be set in concrete?

A general rule is to embed the post one-third of its total length, or at least 24 inches deep, depending on frost line, soil conditions, and fence height. Always add a gravel base beneath the post for drainage and fill the rest with mixed concrete up to ground level for stability.

Is this post compatible with all aluminum fence panels and gate systems?

The post is compatible with most modern aluminum fencing systems that use standard 3″ profile accessories and brackets. Always verify hole spacing, connection hardware, and finish color to ensure a seamless fit when combining with panels, gates, or corner components.

Does the heavy-duty aluminum post require maintenance?

Maintenance is minimal. Simply rinse occasionally with soap and water to remove dirt or salt, especially in coastal areas. Check brackets, hinges, and caps twice per year to tighten any loose fasteners. With basic care, the powder-coated aluminum finish will retain its look for decades.