Description

Product Description

Product Specifications:

- Material: High-quality aluminum, powder-coated wood grain teak finish

- Panel Dimensions: 5 ¼” wide × 3 ¼” thick × 228” long

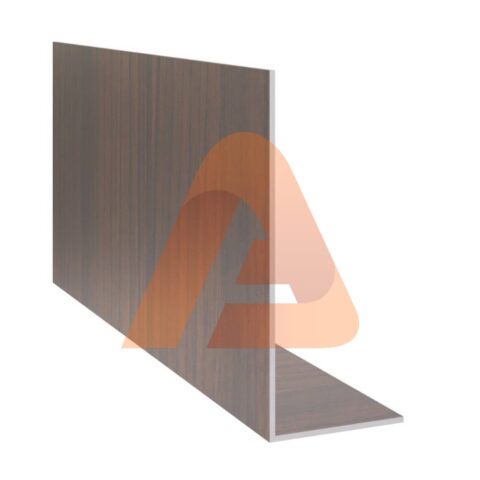

- Design: Single-piece profile mimicking three narrow planks

- Installation: Lego-style interlocking system – only screws required

- Custom Colors Available for Bulk Orders

Ideal Applications:

- Teak-look aluminum siding panels for homes and commercial buildings

- Ceiling coverings for warm, natural aesthetics

- Patio covers and outdoor barbecues for stylish, durable protection

- Decorative wall panels for interior and exterior spaces

- Modern wood facade systems for a contemporary yet classic appeal

Key Benefits of CLAD 120 Wood Grain Teak Cladding:

- Authentic Teak Wood Aesthetic: Natural wood grain finish provides the warmth of teak without maintenance

- Effortless Installation: Interlocking panels ensure a seamless, professional look with minimal labor

- Lightweight Yet Durable: Easy to handle while maintaining exceptional strength

- Low-Maintenance Solution: No painting, sealing, or refinishing required

- Custom Color Options: Bulk orders can be customized with alternative wood grain finishes

Designed to replicate the appearance of three narrow wooden planks in a single-piece panel, CLAD 120 offers a seamless, high-end aesthetic with an easy-to-install interlocking system. The realistic wood grain finish in teak delivers the rich, golden hues of natural wood, while the aluminum construction ensures long-lasting performance without the upkeep of traditional wood siding.

Effortless Installation – Interlocking “Lego-Style” System

CLAD 120 is engineered for fast, simple installation. The panels interlock seamlessly, just like a Lego system, ensuring a secure, polished finish with minimal labor. With only screws required, this single-system aluminum cladding provides maximum efficiency and durability.

Why Choose CLAD 120 Aluminum Over Real Teak Wood?

- One-Piece, Three-Plank Design: Delivers a multi-panel wood look without complex installation

- Zero Maintenance: No need for staining, oiling, or sealing, unlike real teak wood

- Weather-Resistant & Durable: Handles rain, humidity, and UV exposure without fading or warping

- No Warping or Cracking: Real wood expands and contracts—aluminum remains stable in all climates

- Fire-Resistant & Pest-Free: Does not attract termites or pose a fire hazard like wood

- Eco-Friendly Alternative: Aluminum is 100% recyclable, offering a sustainable wood alternative

Versatile Applications for CLAD Aluminum Systems

Our CLAD-100 and CLAD-120 aluminum wall cladding systems are not just for walls—they can also be used to enhance and customize gates, fences, wall toppers, and sliding gates. The durable aluminum panels can be seamlessly integrated within the frame or mounted on the frame, offering a modern, high-end aesthetic with exceptional durability.

Ideal Uses:

- Gate Paneling: Use CLAD panels to create fully enclosed pedestrian gates, double swing gates, and sliding gates

- Fence Enhancement: Install as infill panels for aluminum or steel fence frames

- Wall Toppers: Add privacy and style by mounting CLAD panels on top of existing walls

- Custom Finishes: Available in multiple colors and wood grain finishes, allowing for personalized design options

With their easy installation, lightweight structure, and superior weather resistance, CLAD aluminum panels provide a sleek, contemporary look while ensuring long-lasting performance in residential, commercial, and industrial applications.

Do you want to buy?

Additional information

Additional Information

| Wall Cladding Color | Teak |

|---|