Architectural Wall Panels & Cladding for Oregon Buildings

Architectural wall panels are transforming the way buildings across Oregon achieve both striking aesthetics and superior functional performance. From vibrant urban centers like Portland to smaller towns nestled in the lush Northwest landscape, wall panels offer innovative solutions for cladding that combine durability with design flexibility. In an environment where weather resilience is critical, wall panels Oregon deliver reliable protection against moisture, temperature changes, and wear, while allowing architects to explore textures, colors, and materials that elevate a building’s presence. Whether incorporating decorative wall panels that add artistic dimension, metal wall panels that confer a modern industrial feel, or practical shower wall panels and bathroom wall panels engineered for wet areas, these solutions integrate seamlessly into Oregon’s unique architectural fabric. This blog will take an in-depth look at the varieties of wall panel systems growing in popularity, key benefits, and considerations specific to Oregon’s building requirements and stylistic trends.

Table of Contents

Why Wall Panels Are Essential for Oregon Buildings

In Oregon’s diverse architectural landscape, wall panels play a crucial role in both the aesthetic appeal and functional performance of commercial and residential buildings. Whether revitalizing the exterior façade or optimizing interior spaces, wall panels Oregon come in a variety of materials and finishes designed to meet the state’s unique climate challenges and stylistic preferences. From durable metal wall panels that provide weather resistance and modern wall cladding industrial looks to decorative wall panels offering texture and visual interest, these systems contribute significantly to building performance, insulation, and long-term sustainability. Interior applications, such as shower wall panels and bathroom wall panels, further enhance Oregon buildings by combining water resistance, easy maintenance, and design flexibility—ideal for wet environments that require durability without sacrificing style. Growing awareness of energy efficiency and green building standards across Oregon has accelerated adoption of advanced cladding systems that integrate both functionality and architectural elegance. This blog will explore the wide range of wall panel options available in Oregon, highlighting installation considerations, performance metrics, and design trends shaping the future of building envelopes in the region.

Types of Wall Panels Popular in Oregon

Oregon’s atmosphere, characterized by significant rainfall and seasonal temperature variation, demands wall panels capable of withstanding moisture and thermal stress. Commonly, metal wall panels stand out for their robustness, corrosion resistance, and sleek aesthetics favored in commercial and mixed-use developments throughout Portland, Eugene, and Salem. These panels are often fabricated from aluminum or steel with protective coatings tuned to resist Oregon’s humid climate. Meanwhile, decorative wall panels made from materials like fiber cement, composite laminates, or engineered wood bring warmth and artistic flair to both interiors and exteriors. Their easy customization allows architects and designers to achieve distinctive textures, patterns, and color palettes that align with Pacific Northwest design sensibilities. For building interiors, shower wall panels and bathroom wall panels use materials such as acrylic, PVC, or fiberglass that combine waterproofing, mold resistance, and design versatility, meeting both aesthetic and practical demands of moisture-prone spaces in Oregon’s wet environment.

Benefits of Wall Panel Cladding in Oregon Construction

Wall panel cladding systems provide multiple benefits integral to Oregon construction projects. Primarily, they enhance building protection against moisture infiltration—a critical factor in this region known for high annual precipitation. Cladding with properly installed water barriers and flashing systems reduces risks of mold, rot, and structural damage, thereby contributing to healthier indoor environments and longer building lifespans. Furthermore, many wall panel products improve thermal performance by acting as insulated layers that reduce heat transfer, which is crucial for energy-efficient buildings attempting to meet Oregon’s stringent green building codes. Beyond functionality, wall panels create visual impact, enabling architects to experiment with form and surface articulation while enhancing curb appeal. Their modular nature also often expedites installation timelines and reduces construction waste, contributing to lower overall project costs and environmental footprints. In total, wall panels Oregon offer a practical, versatile solution addressing both the climatic challenges and evolving architectural ambitions of the state’s construction sector.

Products

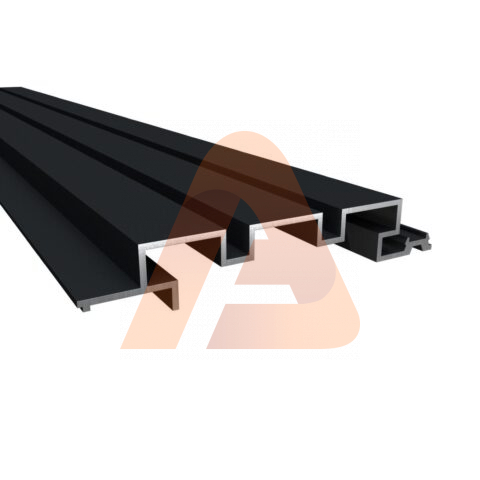

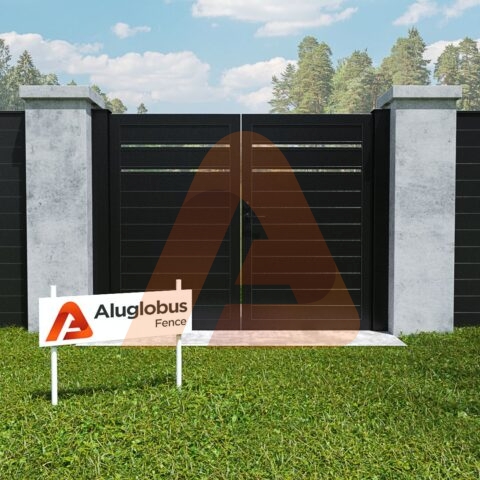

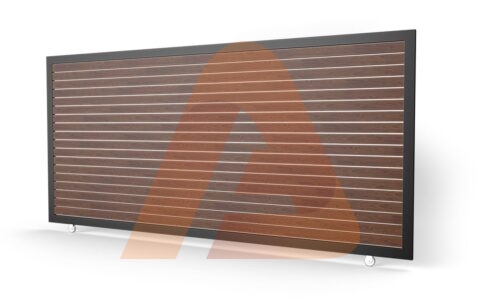

Alu Cladding Clad120 – Black (Aluminum Cladding Panel)

$118.13Product Profiles

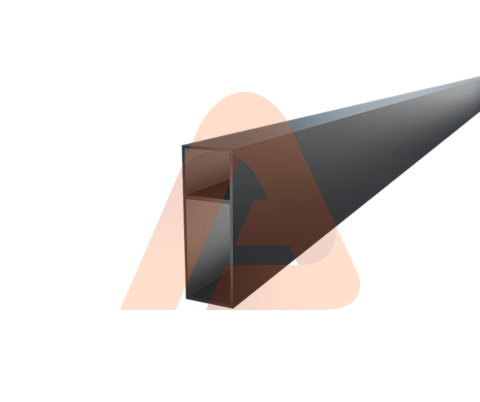

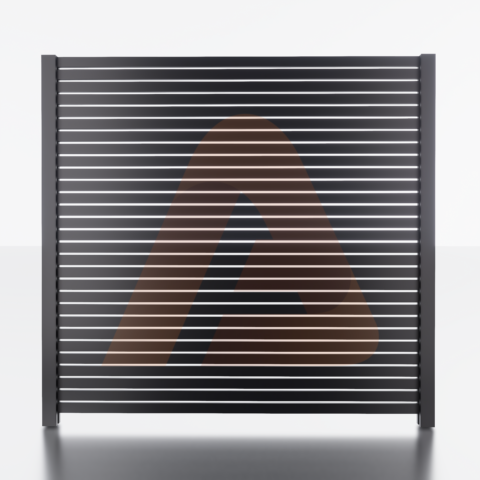

At Aluglobus Fence, our exclusive aluminum fence profiles are designed to offer flexibility, strength, and sleek architectural appeal for any fencing project. From compact and minimal options like ALU15 to more robust and privacy-focused systems such as ALU50 T&G and ALU60, each profile is engineered for long-term outdoor performance. Our lineup also includes hybrid configurations like ALU40+15, giving you the freedom to achieve a modern aesthetic without compromising on privacy or durability. Whether you’re designing for residential, commercial, or custom architectural use, our product profiles deliver refined style and structural integrity backed by professional-grade quality.

Installation Considerations for Wall Panels in Oregon

Proper installation is critical to maximizing the performance and longevity of wall panels in Oregon’s often damp and variable climate. The installation process begins with thorough substrate preparation, ensuring surfaces are clean, level, and free from moisture — vital steps in preventing future problems such as mold or panel detachment. Contractors experienced with Oregon building codes will prioritize weather barriers, flashing, and sealants designed for the regional precipitation levels, including rains and snow prevalent in the coastal and mountainous areas. Depending on the material—whether metal wall panels, fiber cement, or composite decorative panels—the attachment methods differ, with fastening designed to allow for thermal expansion and contraction to avoid buckling or warping. For interior applications such as shower wall panels and bathroom wall panels, waterproof adhesive and proper sealing at joints are essential to prevent water infiltration and ensure maintenance ease. Given the region’s frequent changes in temperature and humidity, Oregon’s installation professionals often incorporate insulated wall panels that contribute significantly to overall building energy efficiency. Accordingly, meticulous application and the use of manufacturer-recommended accessories guarantee that wall panels not only enhance aesthetics but also protect and add functional value throughout Oregon’s diverse environments.

Maintenance Needs Tailored to Oregon’s Climate

While wall panels offer many benefits, understanding and adhering to maintenance requirements is essential for sustaining their appearance and performance over time in Oregon. Exterior metal wall panels boast low maintenance due to their corrosion-resistant coatings but occasionally require washing to remove dirt, mold, or mildew encouraged by the Northwest’s damp air. Specialists often recommend cleaning every six months to preserve finish integrity and avoid surface degradation, especially in urban areas where pollution and weather exposure accelerate wear. For decorative wall panels made of composite or fiber materials, routine inspection for cracks or fading is advisable, with timely touch-ups preserving both functionality and design appeal. Interior shower wall panels and bathroom wall panels, common in Oregon homes, require gentle cleaning with non-abrasive, mold-resistant products to prolong lifespan and maintain their smooth surfaces. In addition to scheduled cleaning, periodic checks to assess sealant and caulking conditions around panel edges help prevent moisture intrusion, a primary concern in Oregon’s moist indoor environments. Proper maintenance matched to the local climate ensures wall panels remain a visually stunning and protective element in both residential and commercial spaces across the state.

Oregon Building Codes and Regulatory Requirements

Navigating Oregon’s building codes and regulatory landscape is an important step when specifying wall panels for any construction or renovation project. The Oregon Residential Specialty Code (ORSC) and Oregon Structural Specialty Code (OSSC) outline specific requirements related to fire resistance, insulation levels, and moisture management that impact the choice and installation of wall panels. For example, certain panels must meet fire resistance class ratings to be compliant in commercial buildings or multifamily housing developments, requiring materials like fire-rated fiber cement or treated metal panels. Energy efficiency standards also influence panel insulation specifications, with initiatives encouraging the use of insulated wall panels that contribute to the state’s environmental goals. Additionally, seismic considerations in parts of Oregon require secure fastening systems capable of handling lateral forces, making professional installation even more critical. Local jurisdictions may impose additional requirements based on location, especially in designated flood zones or historic districts where aesthetic standards control panel appearance. Understanding these codes early in the project allows architects, builders, and contractors to select wall panel solutions that are safe, legal, and aligned with Oregon’s evolving building policies.

Design Trends Shaping Wall Panels in Oregon

Oregon’s building and design community increasingly embraces architectural wall panels as a versatile medium that balances functionality with aesthetics. Contemporary trends favor minimalist, clean-lined panels that emphasize natural textures and colors reflective of Oregon’s rich landscape. Many designers are blending decorative wall panels made from sustainable materials with sleek metal wall panels to create striking contrasts that add depth and sculptural interest. Additionally, there is a growing demand for wall panels that incorporate biophilic design principles, integrating patterns and textures inspired by forests, rivers, and mountains into both interior and exterior cladding. These approaches help buildings connect with their environment and provide occupants with a sense of calm and wellbeing. Customization options extend from subtle hues that blend with Oregon’s misty climate to bold, statement colors that energize urban rooftops and commercial facades. This trend toward personalization aligns closely with Oregon’s progressive architectural ethos that values innovation, sustainability, and regional identity.

Material Innovations Driving Functional Benefits

Recent advancements in wall panel materials have significantly enhanced their practicality in Oregon’s variable climate. Metal wall panels increasingly employ coated steel or aluminum with engineered finishes that improve longevity without sacrificing visual appeal. These metals often include protective layers that withstand corrosion and UV radiation, essential for Oregon’s rainy yet intermittently sunny conditions. Beyond metals, composite panels now integrate recycled content, fire resistance, and thermal insulation into a single product, making them favorites for builders prioritizing environmental certifications such as LEED. For wet interior areas, shower wall panels and bathroom wall panels now feature antimicrobial coatings and seamless joint systems that minimize mold growth while simplifying cleaning routines. Improvements in manufacturing techniques allow panels to be lighter and easier to install without compromising strength, reducing labor costs and installation time. Collectively, these material innovations provide architects and owners with greater confidence that their wall panel choices will perform sustainably and meet evolving building standards in Oregon.

Popular Applications of Wall Panels Across Oregon

Wall panels have found a broad spectrum of applications in Oregon’s diverse built environment. Commercial buildings often use metal wall panels for their durability and sleek modern appearance, enhancing retail centers, office parks, and industrial warehouses with weather-resistant façades that require minimal upkeep. Residential projects leverage decorative wall panels on both interiors and exteriors to create focal walls, enhance curb appeal, and deliver thermal benefits. Inside homes and hospitality venues, bathroom wall panels and shower wall panels replace traditional tile with waterproof, easy-clean surfaces that combine elegance with functionality. Educational and institutional buildings use insulated wall panels to meet acoustic and energy efficiency goals while maintaining aesthetic standards. The adaptability of these panels makes them suitable for both retrofit projects needing quick installation and new construction prioritizing sustainability and design integrity. In every case, wall panels Oregon continue to reshape building envelopes across the state, merging artistry with practicality to meet the needs of a modern generation.

Installation Best Practices for Wall Panels in Oregon

Successful installation of wall panels in Oregon requires meticulous planning and adherence to best practices that account for the state’s distinctive climate and architectural challenges. Installing contractors must first ensure substrates are properly prepared to achieve a moisture barrier capable of resisting Oregon’s high rainfall and fluctuating humidity levels. Selection of fasteners, anchoring methods, and flashing is critical to prevent water infiltration that could lead to structural damage or mold growth behind the panels. Given Oregon’s occasional seismic activity, installations often incorporate flexible mounting solutions that accommodate movement without compromising panel integrity. Specialized training in handling different panel materials—such as metal wall panels which require precision cutting and alignment, or delicate decorative wall panels which demand careful sealing—is a must for installers working in this region. For interior panels like shower wall panels and bathroom wall panels, ensuring watertight joints and proper surface sealing is essential to maintain hygiene and avoid water damage. Attention to detail and compliance with manufacturer instructions and local building codes provide the foundation for long-lasting, aesthetically pleasing wall panel installations that meet Oregon’s exacting standards.

Common Challenges During Wall Panel Installation in Oregon

Despite their benefits, installing wall panels in Oregon can entail several challenges that require foresight and expertise to overcome. The state’s wet climate demands comprehensive waterproofing systems integrated with the wall panel assembly; failure to properly detail these can result in leaks or moisture-related issues such as mold. Uneven or porous substrates may require additional surface preparation, including leveling or treatment to ensure secure adhesion or fastening of panels. In coastal areas, salt exposure can accelerate corrosion of fasteners or metal surfaces if inappropriate materials are used, making corrosion-resistant products a necessity. Temperature fluctuations call for the accommodation of thermal expansion and contraction during panel installation, requiring careful spacing and fastening techniques to prevent warping or buckling. Furthermore, interior shower wall panels face challenges in maintaining seal integrity, especially in high-use commercial or multi-family settings, necessitating high-quality sealants and precise installation to avoid water ingress. Overcoming these challenges demands installers who are well versed in the local conditions and equipped with both the materials and skills to deliver durable, compliant wall panel systems.

Selecting the Right Wall Panels for Your Oregon Project

Choosing the most suitable wall panels for a building in Oregon depends on factors such as climate, building use, aesthetic goals, and budget. Metal wall panels suit projects needing high durability and a modern appearance, excelling in both commercial façades and industrial applications due to their resistance to environmental wear. For clients desiring more decorative or natural textures, fiber cement and composite decorative wall panels provide extensive design flexibility while withstanding moisture and UV exposure. Interior applications like shower wall panels and bathroom wall panels emphasize water resistance, easy cleaning, and mold prevention, often influencing material decisions toward engineered acrylics, PVC, or fiberglass. Cost considerations should include initial material and labor expenses balanced against long-term maintenance and replacement costs, especially in Oregon’s demanding climate. Prioritizing local building code compliance and contractor recommendations can guide the decision process, ensuring the selected panels meet both performance and design expectations. Investing in the right wall panels for Oregon’s unique conditions preserves building integrity, enhances occupant comfort, and boosts aesthetic appeal.

Real-World Applications: Case Studies of Wall Panels in Oregon

Oregon’s architectural community has embraced wall panels in both landmark constructions and smaller-scale projects, demonstrating the scalability and adaptability of these materials. One striking example is the Deschutes Residence designed by Anacapa Architecture, where coated cladding and wall panels integrate seamlessly with natural surroundings along the Deschutes River. The residence features a blend of lava stone, clear pine, and an abundance of glazing complemented by innovative wall panels that contribute to both aesthetic appeal and weather resilience. Such projects highlight how wall panels can enhance connections between buildings and their landscape, particularly in Oregon’s varied environments. Additionally, institutional efforts like the Armed Forces Reserve Center at Camp Withycombe showcase state-of-the-art translucent panel systems balancing daylight optimization with thermal control, demonstrating wall panels’ role beyond simple aesthetics in high-performance building design. These case studies offer valuable insights into material choices, installation techniques, and design integration suited to Oregon’s architectural demands.

Recent Projects Showcasing Diverse Wall Panel Materials

Several recent building projects across Oregon underscore the versatility of wall panels in material and design. Projects vary from commercial office buildings clad in sleek metal panels that express modern industrial aesthetics to residential renovations featuring fiber cement decorative wall panels that provide texture and warmth while withstanding the moist climate. For instance, contractors have been successful in leveraging prefabricated wall panels for rapid installation, reducing construction times and avoiding costly weather delays common in the Pacific Northwest. Multi-family housing developments increasingly specify insulated wall panels to meet energy codes while ensuring residents enjoy comfortable interiors year-round. Interior applications are also prominent, including moisture-resistant shower wall panels that allow for elegant bathroom designs without the vulnerabilities of tile grout. These projects demonstrate how integrating diverse wall panel systems supports Oregon’s need for sustainable, attractive, and efficient building envelopes.

Material Sourcing and Local Availability in Oregon

Sourcing high-quality architectural wall panels in Oregon benefits from a robust local and regional manufacturing network. Fiber cement and composite panels are widely available through distributors that specialize in Pacific Northwest construction materials, often offering panels tailored to moisture and temperature variations typical of the region. Metal wall panels fabricated nearby also provide sustainable options with reduced transportation emissions while ensuring compliance with local building codes. For shower wall panels and bathroom wall panels, many Oregon suppliers carry products designed for the local marketplace, combining code compliance with design trends and warranty coverage. Procurement strategies focus increasingly on suppliers offering eco-friendly, recycled-content materials to support Oregon’s green building mandates. Additionally, regional manufacturing facilities offer custom-sized panels and finishes that allow architects and builders the flexibility to realize complex design visions without compromising timelines. Coordinating with local suppliers enables cost efficiency and timely project delivery within Oregon’s competitive construction environment.

Popular Products

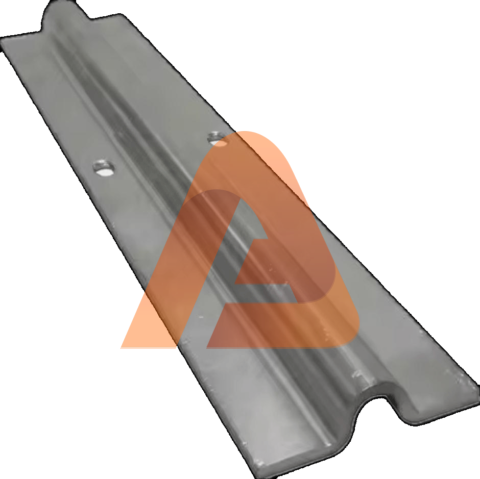

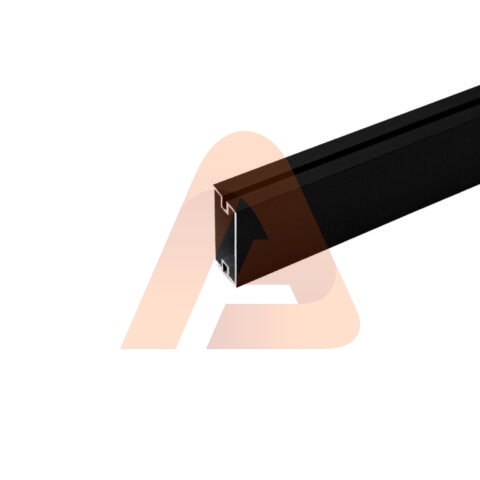

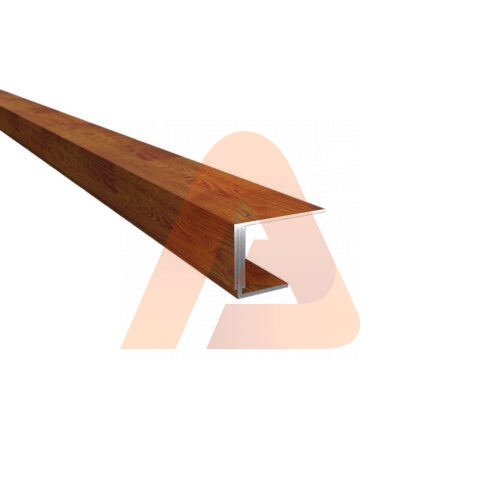

Alu Cladding L-SHAPE 2 pc

$49.35 – $68.25What Our Customers Say

Sustainability and Environmental Benefits of Wall Panels in Oregon

Sustainability is a core value driving the adoption of architectural wall panels across Oregon’s construction industry. Many wall panel products now feature eco-conscious materials and manufacturing processes that align with the state’s strict environmental standards and green building initiatives. Particularly, metal wall panels stand out for their longevity, recyclability, and energy-saving properties. Panels fabricated from aluminum or steel often contain high recycled content and are themselves recyclable at the end of their service life, effectively closing the loop to minimize landfill waste. Furthermore, metal wall panels with reflective coatings reduce solar heat absorption, which supports lower cooling loads and contributes to energy efficiency in commercial and residential buildings throughout Oregon’s varied climate. In addition to metals, fiber cement and composite decorative wall panels sourced from sustainably managed forests or recycled materials further reduce environmental impacts, fulfilling demand from builders prioritizing LEED certification and reduced embodied carbon footprints. These advancements position wall panels as an essential element in Oregon’s sustainable building future, balancing functionality, design, and ecological responsibility.

Advancements in Energy Efficiency and Green Building Certification

Wall panels are increasingly engineered to enhance a building’s thermal performance, a vital consideration in Oregon’s climate where heating and cooling represent a significant portion of energy use. Many modern architectural panels integrate insulation cores or are designed to work compatibly with external insulation systems, improving thermal resistance and reducing heat transfer. These features support compliance with Oregon’s energy code requirements and contribute to achieving certifications under programs like LEED, Energy Star, and the Oregon Residential Specialty Code. The use of insulated metal wall panels, in particular, has surged due to their ability to speed construction, reduce air leakage, and maintain comfortable interior environments with lower energy consumption. This interaction of panel technology and green building practices exemplifies how Oregon’s construction sector is evolving toward highly efficient, sustainable buildings without compromising aesthetic quality or functionality.

The Future Outlook: Trends and Innovations in Wall Panel Technology

As Oregon’s building requirements grow more demanding and architects push the limits of design, wall panel technology continues to evolve rapidly. Innovations such as digitally printed decorative surfaces enable intricate patterns and highly customizable finishes, expanding creative possibilities for architects and designers. Material science advances promise even greater durability and sustainable credentials, including bio-based composites and panels imbued with phase change materials that absorb and release heat to stabilize indoor temperatures. The increasing integration of smart building technology lends new dimensions to wall panels, with embedded sensors for monitoring moisture, temperature, and structural performance gaining traction. These trends indicate a future where wall panels will serve not only as structural and aesthetic components but also as interactive elements contributing to building intelligence and occupant wellbeing. Oregon’s construction landscape stands poised to embrace these innovations, reaffirming the vital role wall panels play in shaping sustainable, resilient, and beautiful built environments.

Product Categories

Whether you’re aiming to boost curb appeal, secure your perimeter, or create a stylish outdoor space, our aluminum-based solutions offer unmatched versatility and lasting quality. We provide a range of finishes, styles, and customizable options to suit residential and commercial projects of any scale. Our team is ready to guide you through product selection, layout planning, and installation support to ensure your vision becomes a reality.

Explore our full range of aluminum fencing systems, profiles, hardware, and accessories to find the perfect fit for your project.

Oregon Wall Panel Manufacturers and Suppliers

Oregon benefits from a well-established network of wall panel manufacturers and suppliers that cater to the state’s unique architectural and environmental needs. Companies such as Oregon Wall Co., located in White City, specialize in prefabricated wood-framed wall panels designed for efficiency and scalability. Their advanced indoor manufacturing processes enable rapid project turnaround, minimizing on-site work and reducing construction waste, which is highly valued in Oregon’s sustainable building community. Additionally, Pacific Wall Systems, headquartered in Phoenix, Oregon, offers precision-manufactured wood panels with a focus on quality control, ensuring components meet exacting standards before reaching the job site. These local manufacturers streamline supply chains and offer product customizations that accommodate regional climate challenges like moisture management and thermal insulation, critical for enduring Oregon’s rainy winters and mild summers. Their proximity to clients allows for just-in-time deliveries, reducing logistical complications and supporting project schedules.

Metal Wall Panel Fabrication and Local Expertise

Several Oregon-based manufacturers specialize in metal wall panels, supplying a variety of profiles and finishes suited for commercial and industrial applications. Companies like Englert offer a full range of metal panel systems produced with durable Kynar coatings that ensure resistance to corrosion and UV damage, critical for longevity in Oregon’s mixed weather conditions. Their product lines include single-skin, concealed fastener, and exposed fastener metal wall panels, allowing designers to choose options that best fit aesthetic and performance criteria. Local expertise extends to custom metal fabrication businesses such as Portland Sheet Metal Works, which provide bespoke solutions tailored to specific architectural requirements, including curved panels, composite systems, and integrated cladding accessories. The robust local metal manufacturing sector ensures Oregon projects benefit from fast lead times, quality assurance due to proximity, and adherence to regional building codes and sustainability requirements.

Prefabricated Wall Panel Solutions and Material Distributors

Prefabricated wall panels have gained significant traction in Oregon as a cost-effective and quality-enhancing building component. Businesses such as Wood Mechanix and Pacific Wall Systems partner to offer off-site manufacturing of wood-framed panels that integrate structural, insulating, and finishing layers in a controlled environment. This off-site production mitigates common on-site challenges, such as weather delays and space constraints, enabling faster build times especially valuable in densely populated areas like Portland. For more specialized panel products, distributors like PG Long provide premium waterproof and decorative wall panels—including shower and bathroom wall panels—geared toward the Pacific Northwest market. These distributors supply products designed to meet local codes and green building standards, often offering customer support and certified installers to ensure proper application. The availability of prefabricated panels and an extensive distribution network equip Oregon builders and architects with versatile options that accelerate construction schedules while maintaining high quality.

Sustainable Architectural Wall Panels from Oregon Manufacturers

Oregon manufacturers are at the forefront of sustainable wall panel production, supplying environmentally responsible products designed to meet the region’s green building standards and stringent environmental mandates. Companies like WD Walls produce high-quality wood paneling sourced exclusively from responsibly managed forests, focusing on renewable species such as Big Leaf Maple and Cherry that ensure long-term forest health through sustainable harvesting practices. This commitment extends into the manufacturing process, which emphasizes reducing carbon footprints and utilizing renewable energy sources where possible. These wood panels not only deliver on sustainability but also promote healthier indoor air quality by avoiding volatile organic compounds (VOCs) common in synthetic materials. Oregon’s sustainability ethos is further exemplified by firms like Sankofa Lumber and Sustainable Northwest Wood, which transform construction wood waste into FSC-certified recycled lumber and architectural panels, closing the loop on wood reuse and contributing to a circular economy that benefits both the environment and the local workforce.

Metal Wall Panel Sustainability and Energy Efficiency

Metal wall panels produced and distributed in Oregon also exhibit substantial sustainability credentials, combining material longevity with advanced energy efficiency features. Brands like PAC-CLAD offer metal panels with solar-reflective coatings that significantly reduce a building’s cooling load, translating to lower energy costs and smaller carbon footprints. These panels are manufactured using high recycled content metal and are fully recyclable at the end of their service life, allowing them to be repurposed without degrading quality. The long operational lifespan of these panels, often exceeding 50 years, means fewer replacements and less material waste over time. This durability, combined with efficient manufacturing and installation practices emphasized by Oregon metal producers, aligns with the state’s aggressive climate action goals and green building incentives. Additionally, the lightweight nature of aluminum and steel panels reduces transportation emissions relative to heavier materials, furthering Oregon’s commitment to sustainable construction.

Collaborative Manufacturing for Sustainable Building Solutions

Oregon fosters a collaborative environment between manufacturers like Pacific Wall Systems and Wood Mechanix, which have pioneered off-site wall panel manufacturing that cuts waste and accelerates construction timelines. By prefabricating wall components in controlled indoor environments, these companies can reduce material scrap and improve precision, which leads to less rework and fewer call-backs on projects. Their integrated business models prioritize zero waste and community involvement, employing local workers and supporting training initiatives to enhance workforce sustainability. This off-site manufacturing approach is particularly well-suited for Oregon’s housing market challenges, offering scalable solutions for affordable, energy-efficient homes that meet the demands of rapidly growing communities. Such collaborations demonstrate Oregon’s leadership in merging sustainable material use with innovative construction methods, enabling builders and architects to create environmentally friendly buildings that do not compromise on quality or design ambition.

Popular Products

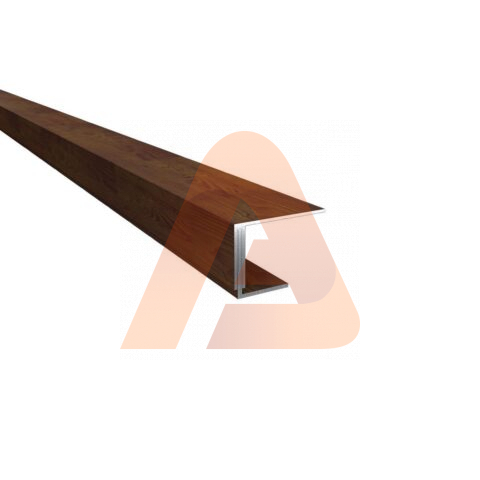

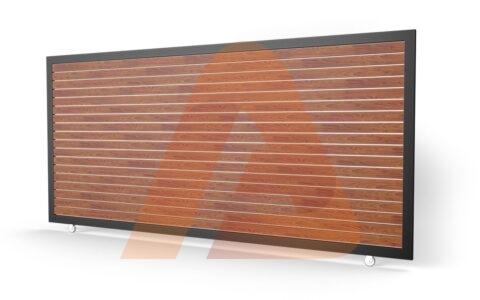

Alu Cladding Clad120 – Woodgrain White Oak (Aluminum Cladding Panel)

$157.50Final Thoughts on Architectural Wall Panels & Cladding in Oregon

Architectural wall panels continue to redefine the building landscape in Oregon by marrying functional resilience with cutting-edge design possibilities. Their ability to withstand the Northwest’s demanding weather—characterized by abundant rainfall, humidity, and temperature swings—makes them invaluable components for both commercial and residential construction. Structural integrity, energy efficiency, and aesthetic versatility ensure wall panels remain a top choice for forward-thinking architects and builders across Oregon’s varied environments. From moisture-resistant shower wall panels and bathroom wall panels enhancing interior spaces to durable metal wall panels and innovative decorative wall panels transforming façades, these systems offer solutions that align with Oregon’s sustainability ethos and design ambitions. Stakeholders investing in well-specified wall panels secure long-term durability, improved building performance, and distinctive visual impact, elevating Oregon’s architectural heritage into the future with confidence and style.

Projects

Frequently Asked Questions

What types of wall panels are best suited for Oregon’s wet climate?

Metal wall panels with corrosion-resistant coatings and fiber cement decorative panels are excellent for Oregon’s rainy conditions due to their moisture resistance and durability. Interior options like waterproof shower and bathroom wall panels are specifically designed to withstand humid indoor environments.

How do architectural wall panels contribute to energy efficiency in Oregon buildings?

Many forms of wall panels incorporate insulating cores or are compatible with external insulation systems, reducing heat loss and cooling loads. This improves thermal performance and supports compliance with Oregon’s energy codes and green building certifications.

Are there local manufacturers in Oregon producing sustainable wall panel materials?

Yes, several manufacturers and suppliers in Oregon specialize in sustainable products, including wood panels sourced from responsibly managed forests and metal panels with high recycled content and recyclability, meeting rigorous environmental standards.

What should I consider when choosing a contractor to install wall panels in Oregon?

Select contractors experienced with Oregon’s climate and building codes, offering transparent estimates, warranties, and a proven track record. Proper installation is critical for ensuring moisture management, structural integrity, and longevity in the state’s wet environment.

Can wall panels be customized for both interior and exterior applications?

Absolutely. Architectural wall panels come in a wide range of materials, textures, colors, and sizes, allowing customization that suits interior aesthetics like bathrooms and showers, as well as exterior façades, enabling cohesive, performance-driven designs.