Want Privacy Without Blocking Light? Try These Laser Cut Panels

- By alupost

- Posted on

Table of Contents

Privacy Meets Illumination: The Revolution of Laser Cut Panel Design

When homeowners think about privacy solutions, they often face an unfortunate trade-off: gain seclusion but lose natural light and ventilation. Traditional solid fences and walls create dark, enclosed spaces that feel more like barriers than boundaries. Laser cut privacy panels have fundamentally changed this equation, offering an architectural solution that delivers both privacy and luminosity in equal measure. These precision-engineered decorative metal screens feature intricate patterns that block direct sightlines while allowing light, air, and visual interest to flow through your space. Unlike conventional privacy barriers made from wood planks or solid vinyl, laser cut panels transform functional necessities into artistic focal points that enhance rather than diminish your property’s aesthetic appeal.

The technology behind these panels represents a significant advancement in both manufacturing precision and design flexibility. Computer-controlled laser cutting machines use high-powered laser beams to slice through aluminum, stainless steel, or corten steel with extreme accuracy, creating patterns and perforations that would be impossible to achieve through traditional metalworking methods. This non-contact cutting process prevents material contamination and deformation while reducing energy consumption compared to conventional cutting techniques. The result is clean, smooth edges and complex geometric or organic designs that maintain structural integrity while providing the perfect balance between openness and enclosure. For residential properties in Orange County, Southern California, and throughout coastal regions where outdoor living spaces are highly valued, laser cut privacy panels have become an essential design element that addresses multiple needs simultaneously—privacy, light transmission, ventilation, security, and architectural distinction.

Understanding Light Transmission Through Perforated Design

The science behind how laser cut privacy panels balance privacy with illumination lies in a concept called “open area percentage”—the ratio of void space to solid material within each panel. This percentage directly affects how much light passes through the screen, how much ventilation occurs, and the degree of visual privacy achieved from various viewing angles. Most decorative laser cut panels designed for residential privacy applications feature open area percentages ranging from 30% to 70%, with each percentage point representing a carefully calculated trade-off between competing priorities. Panels with lower open area percentages, typically between 30% and 40%, provide maximum privacy by limiting direct sightlines while still allowing diffused light to filter through the perforations. These denser patterns work exceptionally well for ground-level applications where neighbors or passersby might otherwise have clear views into patios, pool areas, or first-floor windows.

Conversely, panels with higher open area percentages, ranging from 50% to 70%, prioritize light transmission and ventilation while maintaining visual disruption that obscures detailed views. The perforated pattern creates what designers call “visual confusion”—the human eye struggles to focus through the repeated geometric or organic shapes, providing functional privacy even when substantial open space exists within the design. Research on metal screens used in architectural applications has demonstrated that perforated panels with 40% open area can reduce visible light transmission by approximately 50% at perpendicular viewing angles, but this reduction increases dramatically as the viewing angle becomes more oblique. At 60-degree angles, the same panels may block 85% or more of the view, creating effective privacy barriers without completely eliminating natural light penetration. This angular performance characteristic makes laser cut panels particularly effective for residential privacy applications, since most unwanted viewing occurs from oblique angles rather than straight-on perspectives.

The pattern geometry itself significantly influences light transmission behavior beyond simple open area calculations. Smaller perforations with tighter spacing create more consistent privacy across all viewing angles, while larger perforations with wider spacing allow more dramatic light patterns but may compromise privacy at certain angles. Staggered or diagonal hole patterns prove particularly effective at disrupting sightlines compared to simple linear arrangements, since they eliminate clear viewing corridors through the panel. When illuminated, these intricate patterns produce captivating shadow effects that change throughout the day as the sun’s position shifts, casting dynamic decorative patterns on adjacent surfaces and transforming static barriers into living architectural features. This interplay between light and shadow represents one of the most compelling aesthetic advantages of laser cut privacy panels, adding visual interest and artistic dimension that conventional privacy solutions simply cannot match.

Ventilation Advantages That Solid Barriers Cannot Provide

Beyond their remarkable ability to balance privacy with natural light, laser cut privacy panels deliver another critical benefit that solid fencing and walls completely obstruct: continuous air circulation. In outdoor living spaces, particularly in warm climates like Orange County and throughout Southern California, ventilation directly impacts comfort levels and usability during hot summer months when stagnant air can make patios and decks uncomfortably warm. The perforations in laser cut panels create countless pathways for breeze penetration, allowing natural wind patterns to flow through outdoor spaces rather than creating dead air zones behind solid barriers. This continuous airflow helps moderate temperatures in screened areas, dissipates cooking smoke from outdoor kitchens, and prevents moisture accumulation that can lead to mildew on nearby furniture and structures.

The ventilation performance of perforated metal panels extends beyond simple comfort considerations to include important structural and maintenance benefits. Solid privacy walls and fences act as wind barriers that create significant pressure loads on their structure, particularly during strong wind events that are common in exposed coastal locations. These pressure loads require heavier posts, deeper footings, and more robust framing systems to prevent the entire structure from shifting, leaning, or failing under sustained wind pressure. Laser cut panels, by contrast, allow substantial wind passage through their perforations, dramatically reducing the structural loads imposed on mounting systems and supporting posts. This reduction in wind resistance translates directly to lower installation costs, since lighter-duty mounting hardware can safely support perforated panels that would require much heavier engineering if constructed as solid barriers.

The open structure of laser cut panels also eliminates several common maintenance issues that plague solid privacy barriers. Solid walls trap leaves, debris, and moisture against their surfaces, creating conditions that accelerate deterioration of both the barrier itself and adjacent landscaping. Water that accumulates along solid fence lines cannot drain properly, leading to soil saturation, root rot in nearby plants, and potential foundation issues for structures located near the barrier. Perforated panels allow rainwater to pass through freely, maintaining natural drainage patterns and preventing moisture accumulation. This drainage characteristic proves particularly valuable in landscaped areas where irrigation systems operate regularly—excess water simply passes through the panels rather than pooling along fence lines. Additionally, the airflow through perforated designs accelerates drying of any moisture that does contact panel surfaces, reducing opportunities for corrosion, mildew growth, and material degradation that compromise the longevity of outdoor structures.

Geometric Patterns: The Modern Language of Contemporary Design

When deciding on laser cut privacy panels, the pattern selection becomes the defining characteristic that transforms a functional barrier into an artistic statement. Geometric patterns represent the most popular category of laser cut designs, particularly among homeowners with contemporary or minimalist architectural styles. These designs range from simple linear grids and hexagons to complex tessellating patterns and randomized arrangements that create sophisticated visual interest without appearing overtly decorative. Modern geometric patterns work exceptionally well on Orange County properties because they complement the clean lines, open floor plans, and minimalist aesthetic that dominate coastal contemporary architecture. Hexagonal perforations create a honeycomb-like appearance that catches light beautifully throughout the day, while chevron or diagonal patterns add dynamic directional movement to otherwise static wall surfaces. Randomized geometric arrangements, sometimes called “controlled chaos” patterns by designers, deliberately break symmetry in carefully calculated ways that feel intentional rather than random.

The mathematical precision required to generate these complex geometric patterns highlights one of the most significant advantages of laser cutting technology over traditional metalworking methods. Computer-aided design software allows designers to model exactly how light will pass through geometric perforations from multiple viewing angles and times of day, ensuring the finished panels deliver the intended balance between privacy and visibility. When installed on Orange County properties, geometric laser cut panels often complement existing architectural features such as window patterns, roofline angles, and material textures, creating a cohesive design language that extends throughout the property. For homeowners seeking a sophisticated, design-forward aesthetic that projects contemporary elegance without excessive ornamentation, geometric patterns provide the ideal solution.

Organic and Nature-Inspired Designs: Bringing Natural Elements to Metal Structures

Nature-inspired laser cut patterns have emerged as a dominant design trend throughout Southern California, particularly for residential properties seeking to balance their modern structures with landscaping and natural surroundings. These designs feature flowing botanical motifs, leaf silhouettes, wave patterns, and organic curves that soften the industrial nature of metal materials while creating dynamic shadow effects as daylight moves across the panels. Floral-inspired patterns featuring lotus blooms, magnolia flowers, or abstract botanical forms bring movement and life to garden boundaries and courtyard privacy screens, particularly when combined with living plant elements such as climbing vines or vertical gardens. Wave or water-inspired patterns work exceptionally well for coastal properties in Orange County, creating visual connections to the nearby Pacific Ocean while producing mesmerizing shadow play that changes continuously throughout the day.

The aesthetic appeal of nature-inspired designs extends far beyond simple visual interest—these patterns actively improve the overall ambiance of outdoor living spaces by creating connection to the natural world even within the context of manufactured structures. Research on environmental psychology demonstrates that exposure to nature-inspired patterns, even when rendered in metal or architectural materials, reduces stress levels and increases sense of well-being in outdoor environments. Homeowners who incorporate organic laser cut designs often report that their outdoor spaces feel more inviting and relaxing compared to spaces bounded by solid barriers. Additionally, nature-inspired patterns provide superior shadow effects when illuminated by sunlight or artificial lighting, transforming panels into dynamic art installations that engage viewers throughout the day and evening hours. For properties that want to maintain contemporary architectural sophistication while incorporating visual warmth and natural elements, organic laser cut patterns offer the perfect compromise.

Custom Artwork and Personalization: Making Your Design Uniquely Yours

Beyond pre-designed geometric and organic patterns, laser cutting technology enables virtually unlimited customization for homeowners and designers who want their privacy panels to reflect personal taste, family heritage, or brand identity. Modern laser cutting machines can reproduce virtually any two-dimensional image with precise accuracy, including family monograms, artwork, logos, silhouettes, and even photographic-quality detail when appropriate design considerations are applied. This level of customization has transformed laser cut panels from simple functional barriers into personalized architectural features that tell stories about the properties and people who inhabit them. Commercial properties often commission custom designs incorporating business logos or brand imagery, effectively transforming functional fencing into branded marketing elements that extend corporate identity into outdoor architectural space.

The process of commissioning custom artwork for laser cut panels typically begins with design consultation, where clients collaborate with experienced designers to translate their vision into a two-dimensional pattern optimized for metal cutting and light transmission. Designers provide guidance on pattern complexity, void-to-solid ratios, and technical considerations that impact manufacturability while maintaining aesthetic intention. Personal artwork ideas can be developed from family interests—surfboard silhouettes for surfing enthusiasts, music-inspired geometric forms for musicians, or architectural elements that reference cherished travel experiences. Custom personalization adds significant emotional value to outdoor spaces, transforming standard privacy solutions into unique expressions of individual identity that cannot be replicated or purchased elsewhere. For Orange County properties where design distinction and personal expression hold particular cultural value, custom laser cut artwork represents an investment in creating truly one-of-a-kind architectural features.

Design Your Ideal Fence & Gates Today!

Bring your vision to life with premium aluminum fencing, custom gates, and modern cladding solutions crafted to elevate any property.

Schedule A ConsultationShop

Aluminum: The Premier Choice for Coastal and Modern Applications

Aluminum has become the dominant material for residential laser cut privacy panels throughout Southern California and particularly in Orange County, where coastal environments demand materials capable of withstanding salt air, humidity, and intense UV exposure. Aluminum’s natural oxide layer provides inherent corrosion resistance, while modern powder coating applications add multiple protective layers that prevent fading, oxidation, and surface degradation even under extreme environmental conditions. The lightweight nature of aluminum compared to steel or stainless steel options simplifies installation and reduces the structural demands on mounting systems and supporting posts, lowering overall installation costs while maintaining exceptional durability. Aluminum panels respond beautifully to powder coating finishes, accepting color and texture specifications with precision while maintaining consistent appearance across entire installations.

For Orange County applications, powder-coated aluminum laser cut panels offer virtually maintenance-free operation over decades of exposure to coastal conditions. Unlike wood, which warps and rots regardless of protective coatings, or traditional wrought iron, which requires constant vigilance against corrosion, aluminum panels essentially maintain their original appearance with nothing more than occasional rinsing to remove salt deposits. The material’s lightweight characteristics allow installation on lighter-duty support structures compared to heavier steel alternatives, reducing engineering requirements and construction complexity. For property owners throughout Orange County seeking the optimal combination of durability, aesthetics, low maintenance, and cost-effectiveness, powder-coated aluminum remains the most practical and reliable choice for residential laser cut privacy panels.

Stainless Steel: Maximum Resilience for Premium Applications

While aluminum dominates residential applications, stainless steel laser cut panels have gained significant popularity for high-end residential properties and commercial installations where maximum corrosion resistance and premium aesthetics justify higher material costs. Stainless steel’s superior resistance to salt air corrosion makes it the preferred choice for beachfront properties in Orange County where salt spray represents a constant threat to material integrity. The material’s industrial aesthetic appeals to contemporary designers seeking a sophisticated, modern look that projects both strength and refinement. Stainless steel panels require no protective coating and maintain their bright, clean appearance indefinitely without fading, oxidation, or surface discoloration that eventually affects even well-coated aluminum.

The premium price of stainless steel compared to aluminum typically limits its use to luxury residential applications, high-visibility commercial installations, or situations where extreme environmental exposure demands maximum material performance. For beachfront villas in Newport Beach, Laguna Hills, or other premium Orange County coastal locations, stainless steel laser cut panels deliver architectural distinction and uncompromising durability that aligns with property values and owner expectations. The material’s superior performance in extreme environments and its reputation for luxury positioning make it particularly attractive for properties where cost is less significant than durability and long-term aesthetic preservation.

Corten Steel: Weathered Patina and Natural Beauty

Corten steel, also known as weathering steel, represents a distinctive material option for designers and property owners seeking unique aesthetic qualities and natural weathering characteristics that add character and depth to architectural surfaces over time. Unlike conventional steel, corten steel contains copper, chromium, and nickel alloying elements that create a self-protecting patina layer as the material weathers, preventing deep corrosion while developing a distinctive rust-like surface appearance. This natural patina formation creates a dynamic aesthetic that evolves continuously, giving corten panels a living quality that reflects changing seasons and environmental conditions. For designers and homeowners who appreciate vintage, industrial, or eclectic aesthetics, corten steel laser cut panels offer unmatched character and artistic depth.

The distinctive appearance of weathered corten steel complements diverse architectural styles, from industrial lofts with exposed concrete and steel structure to rustic modern estates that embrace natural materials and aged surfaces. In Orange County coastal communities where eclectic design sensibilities blend contemporary and vintage elements, corten steel laser cut panels have become increasingly popular for properties seeking distinctive character without compromising durability. The material requires minimal maintenance beyond allowing natural weathering to occur, and the patina layer actually prevents further corrosion and extends material lifespan indefinitely. While the distinctive appearance of corten steel appeals to design-forward property owners, the limited contemporary aesthetic appeal compared to polished aluminum or stainless steel means corten panels typically appear on luxury estates or creative commercial properties rather than mainstream residential installations.

Powder Coating Options: Creating Visual Impact Through Color and Texture

Powder coating technology has revolutionized the aesthetic possibilities for metal privacy panels, offering hundreds of color options and specialized texture finishes that dramatically expand design flexibility without compromising material durability. Matte black powder coatings have become virtually synonymous with contemporary laser cut privacy panels, projecting sophistication and minimalist aesthetic while providing neutral color that complements virtually any architectural style. Metallics including bronze, champagne gold, and gunmetal create subtle visual interest and catch light to produce dynamic surface effects throughout the day. For orange County properties, natural-inspired powder coat colors including warm taupes, sage greens, and charcoal grays complement coastal vegetation and provide softer aesthetic impact compared to stark black finishes.

Specialized texture finishes have emerged as premium options for luxury residential applications, including wood grain simulations, hammered finishes, and matte textures that disguise fingerprints and surface dust while creating visual sophistication. These advanced finishes require specialized powder coating processes and increase material costs but deliver uncompromising aesthetic refinement for high-end properties. Custom color matching allows designers to coordinate laser cut panel finishes with existing architectural elements including trim, roofing, or landscape hardscape materials, creating visual cohesion throughout property exteriors. For property owners throughout Orange County investing in premium laser cut privacy panels, powder coating finish selection represents a critical design decision that determines how effectively the panels integrate with existing architecture and contribute to overall property aesthetics.

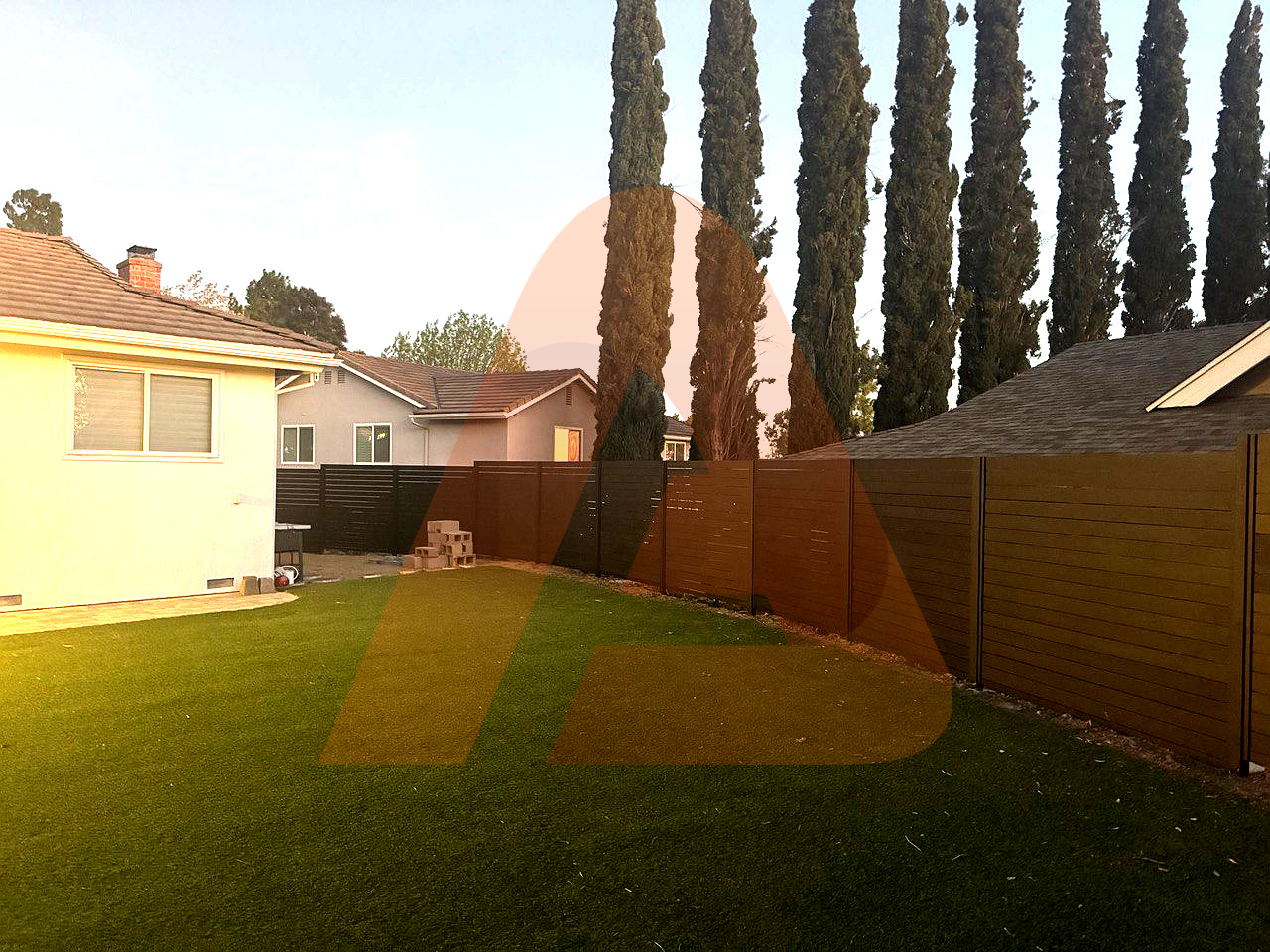

Privacy Screens for Patios and Outdoor Living Spaces: Creating Intimate Retreats

Residential patio and outdoor living spaces have emerged as primary applications for laser cut privacy panels in Orange County, where indoor-outdoor living represents a core value in contemporary home design. Perimeter panels installed around patios effectively eliminate sightlines from neighboring properties and public spaces while maintaining light transmission and ventilation that solid walls completely obstruct. This selective transparency allows homeowners to enjoy outdoor spaces with a genuine sense of seclusion without creating the heavy, enclosed feeling that results from solid barriers. Laser cut patio screens work particularly well in neighborhood settings where properties are closely spaced or situated near major thoroughfares, where traditional solid fencing creates unfriendly barriers while laser cut alternatives maintain neighborhood connection while establishing privacy.

For entertaining, the transparent-yet-private characteristics of laser cut patio panels create ideal environments where guests enjoy outdoor ambiance without feeling observed by distant neighbors. Dinner parties, family gatherings, and social events benefit from the psychological privacy that laser cut screens provide even when substantial portions of each panel remain open to visual penetration. The dynamic shadow effects created as sunlight passes through perforations add architectural interest and visual sophistication to otherwise standard patio spaces, creating an upscale aesthetic that enhances the entertainment value of outdoor environments. Orange County properties with significant outdoor living investments—including built-in seating, outdoor kitchens, or resort-style amenities—integrate laser cut privacy panels to complete sophisticated outdoor room designs that rival interior spaces in terms of design refinement.

Pool Fencing and Recreational Area Screening: Safety Meets Sophistication

Pool fencing represents another major residential application for laser cut privacy panels, where safety requirements combine with design objectives to create unique opportunities for aesthetic expression. California pool code requirements demand fencing that prevents unsupervised access while reducing drowning risks, but laser cut designs satisfy these safety requirements while delivering substantially greater aesthetic refinement compared to conventional pool fence options. Perforated panels allow supervising parents and caregivers to maintain visual contact with swimmers through the fencing structure while preventing unauthorized access from outside the pool area. The refined appearance of laser cut pool fencing has transformed this necessary safety element from a utilitarian fixture into an architectural feature that enhances property aesthetics.

Geometric and abstract laser cut patterns commonly used for pool screening create visually engaging surfaces that transform ordinary fence lines into focal points that draw positive attention rather than appearing as forbidding barriers. The shadow effects produced by sunlight passing through intricate pool fence patterns create dynamic surface treatments throughout the day, particularly appealing when reflected in pool water and enhanced through strategic lighting in evening hours. For properties with resort-style pool amenities or luxury recreational features, laser cut privacy panels integrated into pool fencing designs communicate quality and thoughtful design while fulfilling safety requirements. In Orange County neighborhoods where pools represent centerpiece outdoor amenities, homeowners increasingly specify laser cut fencing to create cohesive design statements that extend throughout entire outdoor spaces.

Balcony and Terrace Screening: Expanding Living Space While Maintaining Views

Balcony and terrace privacy screening represents an increasingly popular application for laser cut panels in multi-story residential properties throughout Orange County’s coastal regions and inland communities. Laser cut balcony panels effectively reduce visibility into private outdoor spaces while maintaining sightlines toward scenic views, ocean vistas, or landscape features that justify outdoor living investments. This selective privacy proves particularly valuable in dense residential settings where balconies overlook neighboring properties or shared amenity spaces—the perforated pattern eliminates mutual visibility while avoiding complete view obstruction. Modern terrace designs increasingly incorporate laser cut screening as architectural features that define outdoor room boundaries, create sun shading, and establish visual separation without sacrificing connection to surrounding landscapes.

The aesthetic sophistication of laser cut balcony panels significantly enhances architectural expression in residential properties, transforming standard exterior balconies into distinctive design features visible from street level and neighboring viewpoints. For multifamily residential developments and high-rise properties in Orange County, coordinated laser cut balcony screening across numerous units creates cohesive architectural identity while allowing individual residents customization within predetermined design parameters. The light and shadow effects created on balcony surfaces throughout the day add visual dimension and artistic interest to exterior facades, particularly when designed patterns are visible from street-level vantage points. Landscape architects and designers frequently specify laser cut balcony panels to create the impression of greater visual continuity between indoor and outdoor spaces, expanding the perceived size of compact residential units while maintaining privacy from adjacent balconies.

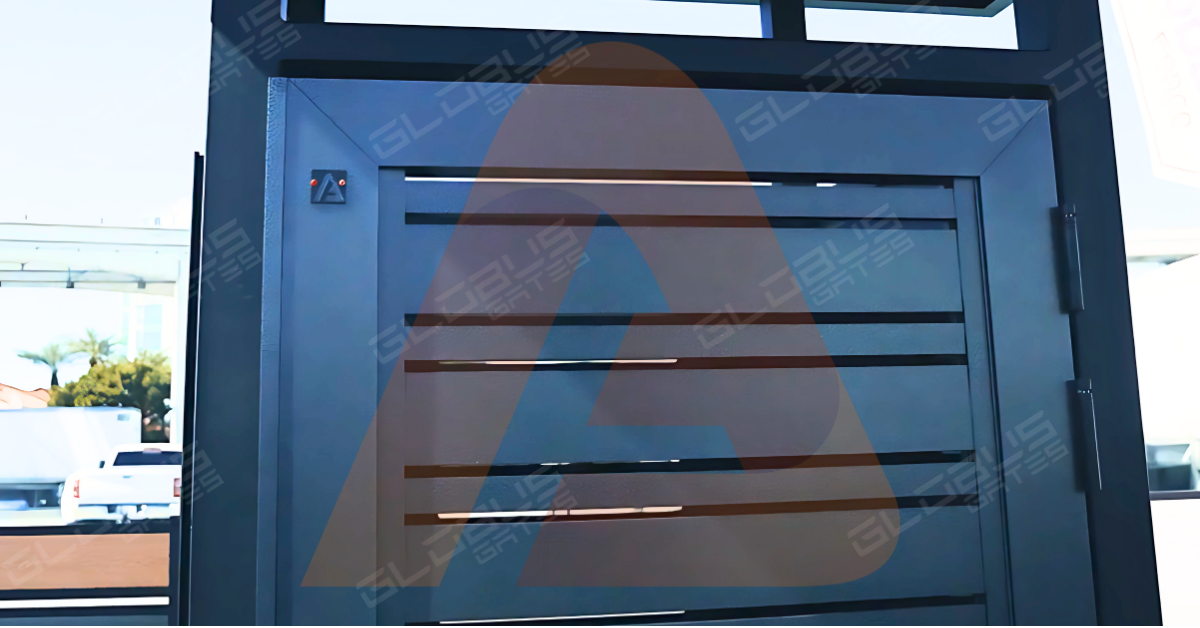

Front Entry Gates and Boundary Fencing: First Impressions and Curb Appeal

Front entry gates and boundary fencing represent high-visibility applications where laser cut privacy panels deliver exceptional impact on property curb appeal and first impressions. Entry gates crafted from laser cut aluminum or stainless steel immediately communicate that a property owner has invested thoughtfully in design details and aesthetic quality. The precision and artistry evident in complex laser cut patterns project sophistication and attention to detail that significantly influences perception of overall property quality and investment value. In competitive real estate markets throughout Orange County, distinctive laser cut entry gates frequently become defining architectural features that potential buyers remember as primary visual impression of a property.

Boundary fencing that incorporates laser cut privacy panels transforms utilitarian property lines into design features that contribute positively to neighborhood aesthetics and strengthen curb appeal. For corner lots and properties with prominent street exposure, sophisticated laser cut fence designs create visual focal points that enhance property value and establish architectural distinction. Unlike traditional solid fencing that blocks views and can appear impersonal or fortress-like, laser cut boundary fencing maintains neighborhood connection while clearly establishing private territory. Orange County neighborhoods where aesthetic standards remain high increasingly feature laser cut privacy panels on entry gates and front boundary fencing, creating streetscapes where individual properties stand out through design sophistication rather than height or mass. The investment in laser cut front fencing typically generates positive return-on-investment through enhanced curb appeal and property value appreciation.

Foundation and Mounting Systems: Creating Structural Integrity

The installation of laser cut privacy panels requires careful engineering and precise execution to ensure structural integrity, proper alignment, and long-term durability, particularly in coastal environments where wind loads and environmental exposure create ongoing stress on mounting systems. Proper foundation design begins with assessment of soil conditions, frost line depth, and anticipated wind loads specific to each property’s geographic location and terrain features. For Orange County properties located near the coast, installation specialists must account for salt air exposure, sandy or unstable soil conditions common in coastal zones, and wind patterns that create significant structural loads on exposed panel systems. Engineer-designed footings sized appropriately for soil bearing capacity and frost depth prevent ground settlement and panel movement that compromise both safety and aesthetic alignment.

Post systems supporting laser cut panels typically utilize aluminum or stainless steel materials selected for corrosion resistance and dimensional stability matching the panel materials themselves. Properly spaced posts—typically 4 to 6 feet apart depending on panel dimensions and wind exposure—prevent excessive deflection and ensure panels maintain precise alignment and geometric pattern integrity over time. For applications requiring maximum wind resistance and structural performance, welded post systems provide superior strength compared to bolted connections, particularly for tall screens or panels in high-wind exposure locations. The engineering complexity of residential laser cut panel installation typically requires professional consultation and certification, particularly for applications exceeding 6 feet in height or requiring compliance with local building codes and safety standards. In Orange County coastal communities, experienced installation contractors understand unique environmental conditions and implement specialized techniques ensuring long-term performance under challenging environmental circumstances.

Alignment and Pattern Precision: Maintaining Design Integrity

Maintaining precise geometric alignment throughout laser cut panel installation proves critical for preserving design intention, ensuring consistent pattern appearance, and maximizing shadow effects and light transmission benefits that distinguish laser cut applications from conventional privacy solutions. Installation specialists use laser alignment equipment and digital measurement tools to verify that panel patterns align accurately with design specifications, creating seamless transitions between adjacent panels and establishing geometric precision that serves both aesthetic and functional purposes. Slight misalignment that might appear minimal during installation can amplify visually across large panel arrays, disrupting pattern flow and undermining sophisticated design intent. Professional installation teams typically perform mock-up assembly and dimensional verification before final installation, identifying and correcting misalignment before permanent fastening.

The dimensional precision of laser cut fabrication sets these panels apart from traditional metalwork, where minor fabrication variations accumulate across multiple panels and create visible inconsistencies. Modern laser cutting machines maintain tolerances within fractions of millimeters, allowing installation specialists to achieve near-perfect geometric alignment that creates the impression of single unified surfaces rather than collections of separate panels. For designers specifying laser cut panels where pattern continuity across multiple panels represents critical aesthetic concern, professional installation with precision alignment capability proves essential. Orange County installation firms experienced with laser cut applications understand these precision requirements and implement procedures ensuring finished installations maintain complete design integrity and visual cohesion.

Weatherproofing and Corrosion Prevention: Long-Term Protection

Proper weatherproofing and corrosion prevention measures implemented during installation significantly influence the long-term performance and appearance maintenance of laser cut privacy panels, particularly in coastal environments where salt air and moisture represent constant threats to metal material integrity. High-quality fastener selection utilizing stainless steel, marine-grade hardware prevents corrosion of connections where galvanic corrosion risk exists between dissimilar metals in contact with moisture. Joint and connection sealing using marine-grade silicone prevents water infiltration into fastener holes and prevents moisture entrapment that accelerates corrosion around connection points. For powder-coated aluminum or stainless steel panels where any edge exposure remains after cutting and fabrication, protective edge sealing prevents moisture infiltration into material layers and avoids corrosion propagation from edge surfaces.

Installation specialists in Orange County with experience in coastal applications understand that meticulous attention to weatherproofing details during installation dramatically extends panel lifespan and preserves finish appearance indefinitely. Properly sealed and fastened laser cut panels maintain original appearance and perform flawlessly for twenty or more years in coastal salt air environments, while inferior installation practices result in corrosion, fastener deterioration, and finish degradation beginning within just a few years. The relatively modest additional cost of premium fasteners and professional-grade weatherproofing measures during installation represents exceptional value when compared to premature panel replacement or extensive restoration work required for corroded installations. For Orange County properties where initial investment in laser cut panels reflects significant financial commitment, ensuring professional installation with comprehensive weatherproofing measures proves essential to protecting investment and maintaining long-term performance.

Routine Cleaning and Care: Preserving Finish Appearance

Laser cut privacy panels constructed from powder-coated aluminum, stainless steel, or corten steel require remarkably minimal maintenance compared to traditional privacy barriers, with routine care consisting primarily of periodic cleaning to remove environmental dust, salt deposits, and atmospheric pollutants. For coastal Orange County properties where salt air creates visible deposits on outdoor surfaces, biannual or post-storm rinsing with fresh water prevents salt accumulation that degrades powder coating finish and accelerates corrosion. Simple garden hose rinsing with no specialized cleaning products typically proves sufficient for maintaining clean panel appearance, as the smooth surface finish of laser cut metal panels resists dirt accumulation and staining that plagues textured materials. For stubborn staining or salt residue buildup, mild soap solutions and soft-bristle brushing remove deposits without damaging powder coating or corroding underlying metal surfaces.

The dramatic maintenance advantage that laser cut metal panels provide compared to wood, vinyl, or traditional wrought iron fencing represents one of the primary value propositions justifying initial investment in these premium privacy solutions. Wood fencing requires regular sanding, painting, and staining to maintain appearance and prevent rot, with maintenance cycles repeating every 3-5 years depending on climate exposure. Vinyl fencing, while lower maintenance than wood, still requires occasional chemical cleaning to prevent mildew growth and staining that accumulates over years of outdoor exposure. Traditional wrought iron fencing demands constant vigilance against corrosion, requiring regular painting and touch-up work to prevent rust from spreading across panels. By comparison, laser cut aluminum or stainless steel panels maintain their original appearance indefinitely with nothing more than occasional water rinsing and periodic soap cleaning. For Orange County property owners seeking to minimize ongoing maintenance commitments while preserving premium appearance indefinitely, laser cut privacy panels represent the ultimate low-maintenance privacy solution.

Inspection and Early Issue Detection: Preventing Premature Deterioration

While laser cut metal privacy panels generally perform exceptionally well without requiring maintenance, periodic visual inspection allows early detection of any potential issues and prevents minor problems from developing into significant deterioration requiring expensive restoration. Annual visual inspection of fasteners, post connections, and mounting hardware identifies any corrosion or deterioration before structural integrity becomes compromised, allowing simple corrective measures such as fastener replacement or touch-up coating application. For coastal properties, post-storm inspection verifies that panels maintained proper alignment and suffered no damage from wind, debris impact, or other weather-related events. Early detection of paint chips, scratches, or other coating damage allows immediate repair application preventing moisture infiltration and corrosion propagation from exposed metal areas.

Orange County property owners who maintain proactive inspection schedules and address minor issues immediately typically find that their laser cut privacy panels perform flawlessly for twenty or more years without requiring significant restoration or repair work. The low cost and minimal labor requirements for addressing minor issues detected through regular inspection make periodic examination an excellent investment in protecting long-term panel performance. Visual inspection typically requires only 15-30 minutes per year and can often be combined with other routine property maintenance activities. For property owners seeking to minimize maintenance burden while preserving investment value and appearance, annual inspection of laser cut privacy panels represents a cost-effective strategy ensuring decades of reliable performance.

UV Protection and Finish Preservation: Maintaining Color and Gloss

Modern powder coating formulations used on premium laser cut privacy panels include advanced UV protection and stabilization technology designed to prevent fading, color shift, and gloss reduction even under intense California sun exposure that rapidly degrades conventional metal finishes. Quality powder coatings maintain color stability and gloss appearance indefinitely, with laboratory testing demonstrating that well-applied powder coatings resist fading and gloss loss that would completely unravel conventional paint finishes within just a few years. The self-healing properties of modern powder coatings allow minor surface damage from scratches or abrasion to gradually repair and blend, preventing visible damage from accumulating and degrading overall appearance. For Orange County properties, the intense ultraviolet radiation and year-round sun exposure make UV-protected coating selection particularly important—premium powder coatings maintain their original appearance indefinitely, while inferior coatings fade to pale, faded shadows of their original color within just a few years.

Specification of premium powder coating systems during laser cut panel fabrication represents an investment that delivers decades of reliable performance and appearance preservation without requiring refinishing or recoating work throughout the panel lifespan. The marginal additional cost of superior coating systems—typically 5-10% above cost of standard coatings—proves exceptional value when amortized across 20+ year panel lifespan where standard coatings would require refinishing or complete replacement to restore acceptable appearance. For property owners throughout Orange County making initial investment decisions, selecting premium powder coating specifications ensures that long-term maintenance requirements remain minimal and appearance preservation remains automatic without requiring periodic restoration work. The combination of quality material selection, professional application, and premium coating systems creates laser cut privacy panels that maintain flawless appearance and reliable performance throughout decades of ownership.

Cost Analysis and Investment Value

The cost of laser cut privacy panels varies considerably based on design complexity, material selection, panel dimensions, and finish specifications, with residential installations typically ranging from $400-$1,500 per individual panel for pre-designed or custom options. For complete residential privacy installations including multiple panels, support structure, and professional installation, typical costs range from $8,000-$25,000+ depending on total linear footage, design complexity, and structural engineering requirements. Design complexity represents the most significant cost variable, with simple geometric patterns requiring minimal laser cutting time and basic fabrication work proving substantially less expensive than intricate custom artwork or highly detailed nature-inspired designs. Large panel dimensions and higher open area percentages prove more economical than small panels with dense perforation patterns, since larger panels require less supporting structure and allow efficient material utilization with minimal waste.

Material selection significantly influences overall installation costs, with aluminum options proving most economical at $400-$900 per panel for custom designs, stainless steel commanding 30-50% premium pricing for superior corrosion resistance and durability, and premium finishes including specialty powder coatings or corten steel weathering effects adding further cost increments. Installation complexity and site conditions affect labor costs, with simple installations on level ground with good access proving less expensive than projects requiring grading, underground utility relocation, or installation in challenging terrain. Orange County coastal properties often encounter additional costs associated with specialized foundation requirements in sandy or unstable soil, salt air corrosion prevention measures, and experienced contractor expertise commanding premium labor rates. For property owners evaluating laser cut privacy panel investments, understanding cost drivers allows strategic decisions about design complexity, material selection, and installation scope to achieve desired aesthetic outcomes within established budgets.

Long-Term Cost Comparison: Laser Cut Panels Versus Alternative Privacy Solutions

When evaluated across typical 20+ year ownership periods, laser cut privacy panels demonstrate superior cost-effectiveness compared to virtually all alternative privacy solutions despite higher initial installation costs. Pressure-treated wood fencing, though significantly less expensive to install initially at $15-$30 per linear foot, requires complete fence replacement every 15-20 years due to rot, termite damage, and weather deterioration. Over thirty-year periods, multiple complete fence replacements and ongoing maintenance make wood fencing far more expensive than initial laser cut panel investment. Vinyl fencing eliminates wood deterioration concerns but still requires periodic chemical cleaning to prevent mildew staining, develops brittleness in extreme heat, and typically requires partial replacement after 15-20 years of outdoor exposure. Wrought iron fencing, though aesthetically appealing, demands constant vigilance against corrosion and requires regular repainting every 3-5 years to prevent rust development.

Laser cut metal privacy panels, by contrast, require no painting, staining, or protective coatings—just periodic water rinsing to remove dust and salt deposits. Over thirty-year ownership periods, maintenance costs remain virtually nil, and panels maintain their original appearance and functional performance indefinitely without requiring significant repair work or partial replacement. Cost-benefit analysis comparing laser cut panels to wood, vinyl, or wrought iron alternatives consistently demonstrates that apparent premium initial cost disappears when evaluated across realistic 20-30 year ownership periods, with laser cut panels becoming the most economical option. For Orange County property owners making privacy solution investment decisions, recognizing that laser cut panels represent superior long-term value despite higher initial cost helps justify investment and aligns expectations with decades of reliable, maintenance-free performance.

Property Value Enhancement and Return on Investment

Beyond direct cost-benefit analysis, laser cut privacy panels provide significant return-on-investment through property value enhancement and curb appeal contribution that exceeds the cost of original installation. Real estate studies document that distinctive architectural features including custom privacy fencing, entry gates, and design-forward exterior elements increase property appeal and sales value substantially—often recovering 75-100% of installation costs through sale price premiums. In competitive Orange County real estate markets where design sophistication strongly influences buyer perception and property valuation, laser cut privacy panels frequently become defining features that justify premium pricing and accelerate property sales. Commercial properties benefit similarly, with custom laser cut architectural elements including branded gates and signature screening features enhancing business image, customer perception, and property asset value.

The psychological impact of distinctive laser cut privacy panels on property perception extends far beyond simple appearance factors—these installations communicate quality, sophistication, and intentional design that influence buyer confidence and negotiating positions. Properties featuring custom laser cut entry gates and premium privacy screening often command price premiums of $15,000-$50,000+ compared to comparable properties with standard privacy barriers. When these price premiums are compared against typical installation costs of $8,000-$25,000, the return-on-investment becomes apparent and substantial. For Orange County homeowners considering privacy enhancement investments, specification of laser cut panels rather than conventional alternatives represents a strategic decision that protects and enhances property asset value while delivering decades of superior function and appearance.

Cost Analysis and Investment Value

| Privacy Solution Type | Initial Cost per Linear Foot | Lifespan (Years) | Annual Maintenance Cost | 30-Year Total Cost |

|---|---|---|---|---|

| Laser Cut Aluminum Panels | $150-$250 | 30+ | $25-$50 | $5,250-$9,000 |

| Laser Cut Stainless Steel | $200-$350 | 40+ | $20-$40 | $6,600-$11,700 |

| Pressure-Treated Wood Fence | $15-$30 | 15-20 | $150-$300 | $7,950-$13,500 |

| Vinyl Privacy Fence | $25-$45 | 20-25 | $75-$150 | $5,625-$10,125 |

| Wrought Iron Fence | $60-$100 | 25-30 | $200-$400 | $12,000-$18,000 |

| Solid Block Wall | $75-$125 | 40+ | $50-$100 | $9,000-$16,500 |

Design Your Ideal Fence & Gates Today!

Bring your vision to life with premium aluminum fencing, custom gates, and modern cladding solutions crafted to elevate any property.

Schedule A ConsultationShopStrategic Lighting Design: Transforming Panels Into Dynamic Art Installations

One of the most transformative yet frequently overlooked opportunities with laser cut privacy panels involves strategic lighting integration that elevates these architectural elements from static barriers into dynamic art installations that change dramatically from day to night. During daylight hours, laser cut panels create captivating shadow patterns as sunlight passes through their intricate perforations, casting geometric or organic shapes onto adjacent surfaces that shift and evolve as the sun’s position changes throughout the day. As evening approaches and natural light fades, carefully positioned artificial lighting transforms these same panels into glowing focal points that project entirely different visual effects, creating dramatic ambiance that extends outdoor living hours and enhances nighttime property aesthetics. The interplay between light source positioning, panel pattern complexity, and surrounding surface materials creates unlimited design possibilities ranging from subtle ambient illumination to bold artistic statements that define outdoor entertainment spaces.

Uplighting represents the most popular and effective technique for illuminating laser cut privacy panels, where ground-mounted or recessed fixtures project light upward through panel perforations to create dramatic silhouettes and shadow effects on walls, ceilings, or overhead structures. LED strip lighting concealed behind panels produces elegant backlit effects where the panel itself appears to glow, with light escaping through perforations to create ethereal illumination that emphasizes pattern intricacy while providing functional ambient lighting. Wash lighting from offset angles highlights the three-dimensional depth of laser cut patterns, creating visual interest through shadow and relief effects that disappear under direct frontal illumination. For Orange County properties where outdoor entertaining represents significant lifestyle component, integrated lighting transforms laser cut privacy panels into entertainment features that enhance evening gatherings, dinner parties, and social events with sophisticated ambiance that rivals high-end restaurant and hospitality installations.

Color-Changing LED Technology: Customizing Mood and Atmosphere

Modern LED lighting technology has revolutionized possibilities for laser cut panel illumination, with color-changing systems allowing property owners to customize lighting effects to match occasions, seasons, or personal preferences through simple smartphone or voice control. RGB LED fixtures can transition through millions of color combinations, creating dramatic effects for special events—warm amber tones for intimate dinner parties, vibrant blues and greens for pool parties, or festive reds and greens for holiday celebrations. Smart home integration allows laser cut panel lighting to coordinate with other outdoor systems including pool lighting, landscape illumination, and entertainment area fixtures, creating unified lighting scenes that transform entire outdoor environments with single commands. Motion-sensor activation provides security benefits while conserving energy, illuminating laser cut entry gates when visitors approach while remaining dark during unoccupied periods.

The dramatic visual impact of illuminated laser cut panels has made these installations increasingly popular for commercial applications where brand identity and customer attraction represent primary objectives. Restaurants incorporate backlit laser cut screens featuring custom logos or artistic patterns that create Instagram-worthy backdrops encouraging social media sharing and organic marketing. Retail properties use color-changing illuminated panels to attract attention, celebrate seasonal promotions, or coordinate with brand color palettes. For residential Orange County properties, smart lighting integration with laser cut privacy panels represents relatively modest additional investment during initial installation but delivers substantial long-term value through enhanced outdoor ambiance, extended usable hours, and impressive visual impact that distinguishes properties from conventional outdoor lighting approaches.

Design Consultation Process: From Concept to Installation

Professional design consultation represents critical first step in successful laser cut privacy panel projects, ensuring that pattern selection, material specifications, and installation approach align with property aesthetics, functional requirements, and budget parameters. The consultation process typically begins with site evaluation where experienced designers assess existing architectural elements, review property lines and setback requirements, identify utility locations that might complicate installation, and discuss functional objectives including desired privacy levels, light transmission preferences, and ventilation requirements. Designers provide guidance on pattern selection appropriate for viewing distances and architectural context—intricate detailed patterns work beautifully when viewed from close range but may appear busy or chaotic when observed from street-level distances, while bold geometric patterns maintain visual impact across longer viewing distances.

Material and finish recommendations consider environmental exposure, maintenance preferences, and aesthetic objectives, with designers explaining trade-offs between aluminum affordability and ease of powder coating versus stainless steel premium durability and industrial aesthetic. Custom pattern development for property owners seeking personalized designs involves iterative collaboration where initial concepts are refined through multiple design revisions, with digital renderings showing how proposed patterns will appear at full scale and how shadow effects will develop under various lighting conditions. For Orange County properties, experienced local designers understand regional architectural trends, environmental challenges specific to coastal or inland microclimates, and permitting requirements that vary considerably between municipalities. The modest investment in professional design consultation—typically $500-$2,000 depending on project complexity—proves exceptional value by preventing costly mistakes, optimizing pattern selection for specific applications, and ensuring finished installations deliver intended aesthetic and functional outcomes.

Emerging Design Trends: What’s Next for Laser Cut Privacy Panels

The laser cut privacy panel industry continues evolving rapidly, with emerging trends in 2025 reflecting broader movements toward sustainability, smart home integration, and increasingly sophisticated design sensibilities. Nature-inspired organic patterns have surged in popularity as property owners seek to soften industrial materials and create visual connections between manufactured architectural elements and natural landscape features. Designers are incorporating increasingly complex botanical motifs featuring layered leaves, flowing vines, and realistic floral details that were impossible to achieve economically before modern laser cutting technology enabled cost-effective complexity. Three-dimensional laser cut panels featuring multiple layered screens create depth effects and enhanced visual interest compared to traditional single-plane installations, though at significantly higher cost and structural complexity.

Hybrid applications combining laser cut metal panels with complementary materials including wood, glass, or living plant elements represent growing trend where laser cut screens serve as armature for climbing plants or backdrop for vertical gardens, merging manufactured precision with organic growth patterns. Smart home integration allowing automated panel movement to track sun position throughout the day, creating dynamic shading that reduces heat gain while maintaining views, represents premium emerging technology currently limited to high-end commercial and luxury residential applications. Sustainability-focused designs emphasizing recycled material content, powder coating systems using bio-based materials, and panel patterns optimized for specific solar angles to maximize passive cooling benefits reflect growing environmental consciousness among designers and property owners. For Orange County property owners considering laser cut privacy panel investments in 2025 and beyond, staying informed about emerging trends allows specification of forward-looking designs that will remain aesthetically relevant and functionally valuable for decades rather than appearing dated within just a few years.

Final Thoughts

Laser cut privacy panels have fundamentally transformed how property owners approach the age-old challenge of balancing privacy, natural light, ventilation, and aesthetic quality in outdoor living spaces. These precision-engineered architectural elements deliver benefits that extend far beyond simple visual screening, creating dynamic outdoor environments where light and shadow interact throughout the day, where natural breezes flow freely, and where sophisticated design elevates ordinary property boundaries into distinctive architectural statements. For Orange County homeowners navigating the complex intersection of coastal environmental conditions, contemporary design preferences, and long-term property value considerations, laser cut privacy panels represent optimal solutions delivering decades of reliable performance with minimal maintenance requirements.

The initial investment in quality laser cut panels, professional installation, and premium finish specifications proves remarkably cost-effective when evaluated across realistic ownership periods, particularly when enhanced property values and curb appeal benefits are factored into comprehensive cost-benefit analysis. Unlike conventional privacy barriers that deteriorate predictably and require periodic replacement, laser cut metal panels maintain their original appearance and functional performance indefinitely, representing genuinely sustainable architectural investments that align financial prudence with environmental responsibility. The design flexibility inherent in laser cutting technology ensures that every property can incorporate personalized patterns reflecting individual taste, architectural context, and functional requirements—transforming utilitarian privacy barriers into expressive artistic elements that define property character and enhance outdoor living experiences.

Whether screening pool areas for safety and seclusion, creating intimate patio environments for entertaining and relaxation, establishing sophisticated entry statements that elevate curb appeal, or defining property boundaries with architectural distinction, laser cut privacy panels deliver unmatched versatility and performance. For property owners throughout Orange County and Southern California who refuse to compromise between privacy and illumination, between function and aesthetics, or between initial cost and long-term value, laser cut privacy panels offer comprehensive solutions addressing every requirement while exceeding conventional expectations for what privacy barriers can achieve.

Design Your Ideal Fence & Gates Today!

Bring your vision to life with premium aluminum fencing, custom gates, and modern cladding solutions crafted to elevate any property.

Schedule A ConsultationShopFrequently Asked Questions

Light transmission through laser cut privacy panels varies based on the open area percentage of each specific design pattern, typically ranging from 30% to 70% of total panel surface area. Panels with 40% open area allow approximately 40-50% of incident light to pass through at perpendicular viewing angles, though this percentage decreases significantly at oblique angles where the perforations appear smaller due to perspective. The pattern geometry also influences light quality, with smaller perforations creating more diffused, even light distribution while larger openings produce more dramatic shadow effects and directional light patterns. Most residential applications specify panels with 40-60% open area, providing substantial natural light penetration while maintaining effective privacy from neighboring viewpoints.

Despite containing substantial open area, laser cut privacy panels deliver excellent functional privacy through visual disruption created by repeated geometric or organic patterns that prevent the human eye from focusing clearly through the perforations. The effectiveness of this visual disruption increases dramatically as viewing angles become more oblique—panels that allow partial visibility at perpendicular angles provide nearly complete privacy when viewed from 45-60 degree angles typical of neighboring viewpoints. Additionally, the distance between the viewer and the panel significantly affects privacy performance, with panels that might allow some visibility from very close range providing complete privacy from distances beyond 15-20 feet. For most residential applications where neighboring views originate from adjacent properties rather than immediate proximity, laser cut panels with 40-50% open area provide privacy equivalent to solid barriers while maintaining light and ventilation benefits.

Properly fabricated and installed laser cut aluminum panels with quality powder coating finishes perform exceptionally well in coastal environments, typically maintaining their original appearance and structural integrity for 30+ years even under constant salt air exposure. The natural oxide layer that forms on aluminum surfaces provides inherent corrosion resistance, while modern powder coating technology adds multiple protective layers preventing moisture infiltration and surface degradation. Critical factors influencing longevity include powder coating quality, fastener material selection (stainless steel or marine-grade hardware), proper weatherproofing during installation, and periodic maintenance consisting of salt deposit removal through water rinsing. Coastal Orange County properties with premium laser cut installations routinely achieve 40+ year service life when quality materials and professional installation practices are employed.

Modern laser cutting technology enables virtually unlimited customization, allowing property owners to incorporate personal artwork, family monograms, business logos, photographic images, and completely original designs into functional privacy panels. The design process typically involves collaboration with experienced fabricators who translate artistic concepts into two-dimensional patterns optimized for laser cutting while maintaining structural integrity and appropriate open area percentages for privacy and light transmission. Design specialists provide guidance on pattern complexity, line weight, and technical considerations ensuring manufacturability while preserving artistic intention. Custom artwork typically requires minimum order quantities and involves design fees beyond standard pattern selection, with total costs varying based on complexity and panel dimensions. For property owners seeking truly unique architectural features reflecting personal identity or brand representation, custom laser cut designs deliver unmatched personalization opportunities.

Laser cut metal privacy panels require remarkably minimal maintenance compared to virtually all alternative privacy solutions, with routine care consisting primarily of periodic water rinsing to remove environmental dust, salt deposits, and atmospheric pollutants. For coastal properties, biannual or post-storm rinsing prevents salt accumulation that can degrade powder coating finishes over extended periods. Stubborn staining or debris accumulation can be addressed with mild soap solutions and soft-bristle brushing, avoiding abrasive cleaners or wire brushes that damage protective coatings. Annual visual inspection of fasteners, connections, and mounting hardware allows early detection of any corrosion or deterioration before structural issues develop. Unlike wood fencing requiring regular staining and painting, vinyl demanding chemical cleaning, or wrought iron needing constant corrosion prevention, laser cut aluminum or stainless steel panels maintain their original appearance indefinitely with minimal intervention. Total annual maintenance time typically amounts to less than one hour for most residential installations, representing exceptional convenience for busy property owners.