Fence Installers near me in Orange County

- By alupost

- Posted on

Table of Contents

Why Local Fence Installers Win in Orange County

If you’re searching for fence installers in Orange County, you’re not buying a brochure—you’re buying results on real streets with real constraints. Coastal neighborhoods like Newport Beach, Huntington Beach, and Laguna Beach load salt into every fastener and morning marine layer into every seam. Inland zones—Yorba Linda, Mission Viejo, Anaheim Hills—bring UV, wind, and slope that punish shallow posts, flimsy rails, and gates built like panels instead of doors. Master-planned tracts in Irvine and Lake Forest add HOA design rules and height caps that don’t care what a national flyer promised. The installers who work here weekly design for those realities: aluminum, vinyl, or composite at the coast with stainless or hot-dip galvanized hardware; cedar/redwood with pressure-treated posts and breathable finishes inland; panels racked to grade (not stair-stepped) where slopes would otherwise telegraph a jagged profile; and gates framed, braced, and hung on adjustable hinges so they don’t rack after the first heat swing. That’s the difference between a fence that still looks deliberate after three summers and one that waves, squeaks, and rusts by Labor Day.

What “Backyard Fence Installation” Really Means Here

Backyard fence installation in OC isn’t just post holes and panels. It’s setbacks, sightline triangles on corner lots, pool-barrier latch heights, and HOA packets that mirror recent approvals—plus corrosion strategy within a mile or two of salt air. Good fence installers verify utilities on older Costa Mesa/Santa Ana lots, choose footing depth by wind exposure (not guesswork), and stage hardware that actually survives your ZIP code. They’ll spec cap-and-trim details that shed water, maintain ground clearance to avoid wicking, and choose finishes that breathe instead of blister under fog/sun cycles. The result: a clean line that stays straight, a gate that closes with one finger, and zero red tags at inspection.

“Privacy Fence Installation Near Me” Without the Headaches

When you type privacy fence installation near me, you want height, quiet, and no drama. Inland, board-on-board or tongue-and-groove wood over pressure-treated posts kills sightlines and noise—if rails are sized for span, posts are deep enough for Santa Ana gusts, and mid-rails are added where kids/dogs lean. On the coast, low-maintenance aluminum or vinyl wins for perimeters; wood can still work in targeted runs if you commit to stainless fasteners, caps that shed water, and a real re-oil cadence. Either way, panels should rack to grade so bottoms track the land cleanly; stepping is for façades that want tiers—not a default because the installer can’t be bothered.

Materials and Specs That Survive OC (Coast vs. Inland)

Materials aren’t a vibe here—they’re survival gear. Along the coast, unprotected steel and film paints fail fast under the fog-to-sun cycle; inland, UV and wind make short work of undersized posts and light rails. Competent fence installers spec aluminum, vinyl, or composite with AAMA-rated powder coats and stainless fasteners at the beach; inland, they pair cedar/redwood boards with pressure-treated posts, deeper augers, UV-stable finishes, and hardware that doesn’t loosen the first time temps swing 30°F in a day. Gates are built as doors: framed leaves, diagonal bracing, adjustable (nylon-lined or greasable) hinges, and compression latches that pull the meeting stile tight so alignment holds through seasons. This is boring, correct craft—and it’s why good installs pass inspection once and stay quiet.

Residential Fence Installation: HOA, Permits, and First-Pass Approvals

Residential fence installation lives or dies on approvals. Newport/Laguna add coastal overlays; Irvine/Lake Forest run everything through HOA design review; hillside pockets in San Clemente/Anaheim Hills scrutinize footing depth and, sometimes, ask for notes on wind exposure. The packet that passes first time looks the same across pro crews: site plan with fence lines inside setbacks and corner visibility triangles; elevations showing finished heights at high/low grade; material and finish specs matched to microclimate; hardware metals named (stainless/HDG); and gate construction spelled out (framed + diagonal brace + adjustable hinges + compression latch). Pros attach two or three nearby approvals with pass dates; tourists attach promises.

Picking by Address: Quick, Practical Guidance

Newport / Huntington / Laguna (coast): Aluminum or vinyl perimeters; stainless/HDG hardware; AAMA 2604/2605 powder on metal; wood only with caps, clearance, and breathable oils.

Irvine / Lake Forest (flat pads, HOAs): Uniform vinyl or aluminum; clean lines in approved colors; gates with underground or clean hardware to keep façades quiet.

Yorba Linda / Mission Viejo / Anaheim Hills (wind & slope): Taller privacy runs with deeper posts, tighter spacing, mid-rails; wood or aluminum; rack panels to grade; overbuild hinge lines.

Say the word and I’ll roll into Chunk 2 next—deep dive on design trends by neighborhood, timelines & lead times that are actually real in OC, and how to read a bid so you don’t get burned.

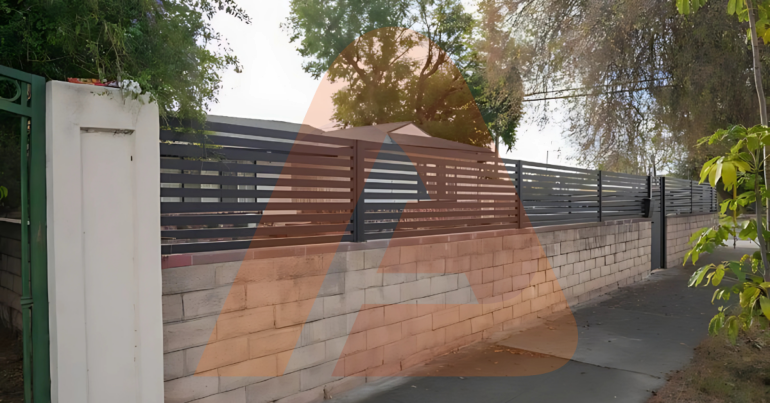

Design by Neighborhood: What Actually Looks Right on OC Streets

Orange County is not one aesthetic, so good fence installers don’t copy/paste a catalog photo; they design to the block. Coastal-modern pockets in Newport Beach, Huntington Beach, and Laguna Beach lean horizontal, matte, and quiet—lines that echo garage cladding and window mullions, hardware that doesn’t rust, colors that don’t glare at noon. Irvine and Lake Forest master-planned tracts reward uniformity and HOA-approved palettes where a clean perimeter reads premium and compliance keeps you out of review purgatory. Yorba Linda, Mission Viejo, and Anaheim Hills bring size and wind; tall privacy runs and heavier frames are normal, but they only look “finished” if posts are deep enough, rails are sized for span, and panels rack to grade instead of stair-stepping every eight feet. Real-world takeaway: pick faces and profiles that match the architecture and sun angle on your street, then engineer the structure so it stays straight—because a good-looking install that waves in month six is a fail.

Coastal-Modern (Newport / Huntington / Laguna): Matte, corrosion-proof, racked—not stepped

Salt, fog, and afternoon sun expose lazy specs instantly. For coastal residential fence installation, aluminum or vinyl perimeters with AAMA-rated finishes and stainless or hot-dip galvanized hardware are the adult choice; wood accents work only with cap-and-trim, ground clearance, and breathable oils that won’t blister in fog/sun cycles. Panels should rack to grade so bottom lines track the land cleanly; stepping creates a visible tooth pattern that screams “stock panel.” For backyard fence installation near the beach, keep irrigation off the fence, isolate dissimilar metals to avoid streaking, and specify gates as framed doors with diagonal bracing and adjustable hinges—otherwise the first humid night plus hot morning will twist the leaf out of alignment and you’ll be filing warranty tickets.

Inland Pads & Hillside Tracts (Irvine / Lake Forest / Yorba Linda / Anaheim Hills): Structure first, cosmetics second

Inland installs live under UV and wind, plus slope in plenty of cul-de-sacs. Privacy fence installation near me here usually means taller board-on-board or tongue-and-groove wood over pressure-treated posts, or aluminum/composite where maintenance time is zero. The only way it looks premium after three summers: deeper augers, tighter post spacing on tall faces, mid-rails where kids and dogs push, and rails sized for span so panels don’t belly. Gates need compression latches that pull the meeting stile tight when temperatures swing 30°F in a day. On slope, racking beats stepping unless your façade wants tiers. This is basic for competent fence installers—and exactly where bargain bids fall apart.

Timelines, Lead Times, and What Actually Delays You in OC

“Two weeks” is marketing unless it accounts for HOA cycles, permit desks, material staging, and weather windows. Newport and Laguna layer coastal rules on top of code; Irvine and Lake Forest run everything through design review; hillside pockets sometimes want engineering notes for footing depth. Real fence installers front-load approvals, book utility locates immediately, pre-order stainless or marine-grade hardware for coastal jobs, and schedule inspections that verify holes before pour where required. They also time finish work around marine layer and afternoon heat so coatings cure right. Inland, smart crews avoid hanging gates the day before Santa Ana winds. The difference between on-time and drift is boring process: packet mirrors recent approvals, materials land before demo, and there’s a written slope/racking plan so field crews aren’t improvising with a neighbor watching.

HOA/Permit Flow That Keeps You Moving

A first-pass packet is predictable: site plan with fence lines inside setbacks and corner visibility triangles; elevations showing finished heights at high/low grade; material and finish specs matched to microclimate; hardware metals named (stainless/HDG); gate construction spelled out (framed leaf, diagonal brace, adjustable hinges, compression latch); and, where relevant, pool-barrier latch heights and swing direction. Pros attach two or three nearby approvals with pass dates so reviewers aren’t guessing. That’s how residential fence installation avoids “revise and resubmit” purgatory while posts sit braced in your yard.

Material Staging and Weather Windows You Can’t Ignore

Coast: stainless hardware and AAMA 2604/2605 powder-coated metal in hand before demo; finish work scheduled for dry, stable conditions (fog morning + 90°F afternoon = ruined film coat); hardware kept boxed until install so salt air doesn’t start corrosion early. Inland: deeper footing gear and mid-rails onsite for tall privacy runs; hinge posts oversized for wind; gate hanging delayed until after a wind event so final tuning sticks. For backyard fence installation, this staging kills 90% of “unexpected” delays. For privacy fence installation near me, it keeps your calendar honest and your fence from needing rescue in month three.

Timelines, Lead Times, and What Actually Delays You

“Two weeks” is fake without context. Orange County timelines hinge on HOA cycles, permit desks, material staging, and weather windows (marine layer + afternoon heat will wreck film finishes). Local fence contractors near me stage approvals and materials in parallel: HOA packet out day one, utility locate booked, stainless or marine-grade hardware pre-ordered for coastal jobs, and inspection slots reserved to verify holes before pour where required. Inland, they watch Santa Ana forecasts before hanging gates so alignment tweaks stick. The laggards? They dig first, submit later, and then you sit with braced posts waiting for a reviewer to return from vacation.

What Blows Schedules (and How Pros Avoid It)

Common killers: missing HOA precedent (packet bounces), non-stainless hardware delivered to a coastal site (reorder), posts too shallow for wind zone (red tag + re-dig), panels forced to grade instead of racked (visible waves), and gates built like fence panels (rack and drag after first heat swing). Competent fence builders dodge all of it with a boring checklist: correct footings, correct metals, breathable finishes where wood is allowed, and gate leaves built as doors with diagonal bracing and adjustable hinges. That’s how you keep the calendar honest.

Reading a Bid Without Getting Burned

If a proposal doesn’t specify post size/spacing, footing depth by zone, hardware metals, finish system, and gate construction, it’s not a bid—it’s a placeholder. The keepers list species (cedar/redwood vs. vinyl/composite), corrosion strategy near the coast, racking on slopes, and exactly how gates are framed and latched. They’ll also show three addresses within five miles of yours. That’s how you separate real fence contractors from price-only tourists—and why paying a little more up front saves you from buying the same fence twice.

Cost, Quotes, and Lifetime Value (Stop Comparing Only the Sticker)

Most Orange County homeowners start with three numbers on a spreadsheet and call it due diligence—and that’s exactly how you buy rework. The real spread between bids from fence installers isn’t labor hours; it’s the invisible lines that keep a fence straight, quiet, compliant, and low-maintenance after three summers. On the coast (Newport Beach, Huntington Beach, Laguna Beach), anything that doesn’t name stainless fasteners, AAMA 2604/2605 powder coat on metal, isolation where dissimilar metals touch, and breathable finishes for wood is a future rust halo or peeling film coat; inland (Yorba Linda, Mission Viejo, Anaheim Hills), shortcuts show up as shallow posts that lean, rails that belly, and gates built like panels that rack the first Santa Ana. Real residential fence installation quotes cost more because they budget for microclimate: deeper footings in wind corridors, racked panels on slope instead of lazy stair-steps, mid-rails where kids and dogs lean, and gate leaves framed like doors with adjustable hinges and compression latches so thermal swings don’t open gaps you can see from the street. That “expensive bid” is usually the only one pricing the fence you think you’re buying—one that passes inspection once, keeps its line, and doesn’t hijack your weekends with repairs.

What a Real Spec Includes (And Why It Matters)

A professional submittal from competent fence installers reads like a build plan, not a flyer: post section and on-center spacing by wind zone; footing depth and mix; named hardware metals (stainless within coastal distances, hot-dip galvanized inland); finish system by environment (AAMA-rated powder on metal, penetrating oil on wood), plus color/texture so HOAs don’t bounce you on aesthetics; panel construction (picture-frame, board-on-board, tongue-and-groove) with a clear slope strategy (rack vs. step) called out; and gate construction spelled in plain English—framed leaf, diagonal brace, adjustable (nylon-lined or greasable) hinges, compression latch, and clear ground/side clearances so leaves don’t plow gravel or sidewalk. For backyard fence installation near pools, it will also note latch heights and swing direction; for corner lots in Costa Mesa or Tustin, it will draw the visibility triangles. When those lines are on paper, inspectors nod instead of red-tagging, HOA reviewers recognize their own precedent, and your install calendar actually holds.

Where Cheap Bids Fail (Predictably)

Common tells: “XX linear feet of fence” with zero structural detail; film paint on coastal steel; strap hinges on a “custom” gate; generic hardware metals “per availability”; panels that will be “trimmed to suit slope” (translation: visible waves in a week); and no mention of fasteners, isolation pads, or finish cadence. In OC, these are not opinions—they’re failure modes. The result is the same story every time: rust freckles in Newport by August, racked gates in Anaheim Hills by the first wind, and stepped panels that telegraph every 8 feet on a gentle Irvine slope. When you ask for fixes, you discover the spec never promised what you assumed. Avoidable—if you insist on the boring details up front for privacy fence installation near me or any other scope.

Gates, Hardware, and Daily Use (Where Most Projects Fail First)

A fence lives or dies at the gate because that’s the only moving part—and it’s where lazy specs hide. In Orange County, the gate that still closes with a finger press after three summers wasn’t “lucky”; it was built like a small door and installed for your street’s geometry. Coastal parcels want stainless hinges, compression latches, and powder-coated or vinyl frames that don’t bloom rust when marine layer hits at 6 a.m. and sun bakes at noon; inland tracts want deeper hinge-post footings, larger hinge hardware, and mid-rails where family traffic leans hard. Side-yard gates for backyard fence installation should clear bins and strollers without bruised knuckles, and driveway wings must respect right-of-way so a leaf never swings into sidewalk or lane. Good fence installers design that on day one, not during punch-list week. They also plan sightlines and latch heights for pool codes, keep irrigation off metal (silent killer), and place stops so leaves don’t slam latches to death. This is mundane, yes—and it’s exactly why the right crew’s fences stay quiet, aligned, and drama-free while the bargain job next door starts squeaking and drifting out of plumb.

Build Gates Like Doors (Not Panels on Hinges)

Gate leaves should be rigid frames with diagonal bracing, not fence boards nailed to a hinge fantasy. Adjustable (nylon-lined or greasable) hinges set co-axial stop chatter and let you tune after the first heat swing; compression latches pull the meeting stile tight so you don’t see daylight at 3 p.m.; hinge posts get larger footings because torque lives there; and clearances at the sweep prevent leaves from plowing decomposed granite or turf. On slopes in San Clemente or Laguna Niguel, sliding driveway gates are the adult call—swing leaves will strike grade—while pedestrian gates rack to the hillside cleanly instead of stepping every panel like a staircase. For residential fence installation near the coast, all exposed metals need AAMA-rated finishes and stainless fasteners; inland, hot-dip galvanized hardware is fine if UV-stable components back it up. Build this way and the gate remains the quietest part of the project, not the weekly support ticket.

Human Factors, Safety, and Code (So You Pass Once and Live Happily)

People should be able to use the fence without contortions—and inspectors should pass it without debate. Latch heights meet code but stay ergonomic; pedestrian gates open away from sidewalks; driveway gates keep arcs out of public right-of-way or switch to sliding when aprons are short; and corner parcels respect visibility triangles so neighbors and drivers aren’t blind at intersections. For privacy fence installation near me at pool lots, self-closing/self-latching behavior and latch positioning aren’t “nice to have”—they’re the difference between approval and a red tag. Competent fence installers add one more layer: maintenance pragmatics. They’ll show you how to rinse coastal hardware, oil wood on a realistic cadence, and tweak hinges after the first Santa Ana so you don’t learn by failure. Do the human and code details right, and the fence becomes invisible infrastructure—quiet, compliant, and out of mind—exactly what you wanted when you started this search.

Backyard Fence Installation That Balances Privacy, Code, and Real Life in OC

When Orange County homeowners search backyard fence installation, they’re really asking for three things at once: privacy from the street and neighboring second-story windows, code-clean details that pass on the first inspection, and day-to-day usability that doesn’t annoy the family or the block. On coastal lots in Newport, Huntington, and Laguna, privacy has to coexist with salt, fog, and glare—so installers lean aluminum/vinyl for perimeters and reserve wood for targeted runs where warmth matters, detailing with cap-and-trim, ground clearance, and breathable oils so boards don’t wick water and blister. Inland in Yorba Linda, Mission Viejo, and Anaheim Hills, height and sound damping take priority; board-on-board or tongue-and-groove over pressure-treated posts kills sightlines and softens road noise—provided posts are deep enough for wind, rails are sized for span, and panels rack to grade instead of stair-stepping every eight feet. Across OC, good fence installers plan trash-bin widths at side yards (40–48 in), keep arcs out of public right-of-way on corner lots, and build gates like doors (framed leaf, diagonal brace, adjustable hinges, compression latch) so alignment stays true through heat swings and marine layer. That’s how residential fence installation becomes invisible infrastructure: quiet, compliant, and easy to live with long after the crew leaves.

Pool-Barrier Rules, Sightlines, and Passing Inspection Once

Pool yards are where “almost right” gets red-tagged. Latch heights, self-closing/self-latching behavior, and swing direction (away from the pool) are non-negotiable, and they’re enforced unevenly across OC—Newport and Laguna overlay coastal considerations, while Irvine and Lake Forest push HOA consistency on top of code. Competent fence installers pre-write those lines into the packet: latch centerlines in inches (not vibes), hardware cutsheets that match the field install, and clear diagrams of swing arcs that don’t cross sidewalks or block egress. On slopes common to San Clemente and hillside Anaheim Hills, they rack panels so bottom lines track the land without wedge gaps that a toddler could exploit, and they set return wings to guard sightlines at corner lots. Near the coast, stainless or hot-dip galvanized hardware is mandatory (salt air will freckle anything else by summer); inland, UV-stable components and deeper augers keep tall privacy faces standing straight through Santa Ana season. If your search is privacy fence installation near me, this is the boring check-list that saves weeks: code boxes ticked in writing, photos of post holes before pour (some cities require it), and a first-pass inspection because the plan mirrored last month’s approvals on your street.

Pets, Kids, Neighbors: Ergonomics That Stop Headaches Before They Start

Real life is bins, strollers, dogs, and deliveries. Side-yard gates sized to 40–48 inches mean trash cans roll without bruised knuckles; kick plates and mower strips keep edges from fraying; and dog-view windows or higher solids tame anxiety barking where alleys carry noise. In coastal ZIPs, installers isolate dissimilar metals to prevent streaking, keep irrigation off faces (overspray is silent death), and use AAMA-rated powder on metal so the fence still photographs clean against white stucco after two summers. Inland, mid-rails at kid/dog height stop boards from bulging, compression latches keep meeting stiles tight when temps swing 30°F in a day, and hinge posts get larger footings so gusts don’t twist gates out of plane. For neighbors, “good-neighbor” construction (alternating rails or picture-frame panels) gives both sides a finished face; on streets with strict visibility triangles, pros taper heights near corners or use open upper bands so inspectors pass and drivers see. That’s backyard fence installation done like adults: ergonomic, durable, and quiet enough that you forget it’s there—exactly what you wanted when you typed “fence installers” in the first place.

Spec & Material Matrix for Orange County (Use This to Decode Bids)

Most confusion with fence installers comes from vague materials talk—pretty renderings, no survivability plan. Orange County splits into microclimates that punish shortcuts differently: salt and marine layer along Newport/Huntington/Laguna; UV, wind, and slope inland across Irvine/Lake Forest/Yorba Linda/Anaheim Hills; funky grades and old utilities in Costa Mesa/Santa Ana. The right choice for residential fence installation shifts with that context, and it isn’t about hype—it’s about which system holds a straight line after three summers, passes inspection the first time, and doesn’t turn maintenance into a side job. Use the matrix below to sanity-check any bid for backyard fence installation or privacy fence installation near me—line by line, with zero guesswork.

| Material | Best OC Zones | Core Strengths | Watch-outs | Typical Gate Pairing | Maintenance (Realistic) | HOA Compatibility |

|---|---|---|---|---|---|---|

| Cedar/Redwood (wood) | Inland privacy runs (Yorba Linda, Mission Viejo, Anaheim Hills); select coastal accents | Warmth, sound damping, hides grade changes, custom widths | Needs cap-&-trim, ground clearance, stainless/HDG fasteners; breathable oils only (no film coats) | Framed leaf, diagonal brace, adjustable hinges, compression latch | Re-oil 12–18 mo coast; 18–24 mo inland; annual rinse | Good where wood is allowed; some HOAs restrict color/height |

| Vinyl | Coastal perimeters (Newport/HB/Laguna) and uniform tracts (Irvine/Lake Forest) | Low upkeep, uniform look, HOA-friendly, corrosion-proof faces | Choose UV-stable product; reinforce rails; plan for expansion gaps | Standard framed vinyl gates with stainless/HDG hardware | Hose-down as needed; hardware check annually | Often preferred by HOAs (approved palettes) |

| Aluminum | Coastal + inland (everywhere); mixed-material modern façades | Lightweight (quieter gates), corrosion-resistant with AAMA 2604/2605 powder, clean lines | Specify stainless fasteners; isolate dissimilar metals to avoid streaking | Aluminum frame gates; underground or clean hardware for façades | Minimal—rinse; hardware/hinge tune yearly | Widely approved; easy to match colors |

| Composite | Inland low-upkeep privacy; some coastal if hardware is stainless | Wood look without frequent refinishing; stable color | Heavier panels—size posts/rails correctly; watch thermal movement | Framed gates with stout hinges; compression latches | Rinse; periodic fastener checks | Generally acceptable; confirm color/texture rules |

How to Use This Without Getting Burned

Match your address to the “Best OC Zones,” then check your bid for the required details: corrosion strategy (stainless/HDG + AAMA powder) within a mile or two of salt air, UV and wind allowances inland (deeper posts, tighter spacing, mid-rails), and a gate spec that reads like a door build—not a panel on hinges. If your fence installers proposal doesn’t call out racking (not stepping) on slopes, post depth by wind zone, and the exact finish system, it’s not a real spec. It’s a future change order.

Design Your Ideal Fence & Gates Today!

Bring your vision to life with premium aluminum fencing, custom gates, and modern cladding solutions crafted to elevate any property.

Schedule A ConsultationFailure Modes (and What Pros Write in the Bid to Prevent Them)

Fences don’t “randomly” fail in OC; they fail in the same ways—salt freckles on non-stainless hardware, film coats peeling under fog/sun cycles, shallow posts leaning in wind, panels stair-stepped on gentle slopes, and gates sagging because someone built a leaf like a fence panel. Competent fence installers preempt all of it in writing: stainless or hot-dip galvanized fasteners, AAMA 2604/2605 powder on metal, breathable penetrating oils for wood, racked panels that follow grade, footing depth tied to wind exposure, and gates framed with diagonals, adjustable hinges, and compression latches. For privacy fence installation near me, they also document corner visibility triangles, pool-latch heights, and swing directions so inspectors pass the first time and you don’t sit with braced posts while packets bounce around.

Gates & Moving Parts: Where Cheap Bids Go to Die

Every fence failure starts at the gate. The fix is not expensive—just disciplined. Hinge posts need larger footings; hinges must be adjustable (nylon-lined or greasable) and co-axial; the leaf needs a rigid frame with a diagonal; clearance must keep the sweep off DG/turf; and the latch should be compression style so thermal swings don’t open daylight. On sloped drives in San Clemente or Laguna Niguel, sliding driveway wings beat swing arcs that strike grade; on flat Irvine pads, double-leaf swing is fine if the structure is real. Your residential fence installation spec should spell this out. If it doesn’t, expect callbacks.

Slope, Grade, and Line Discipline (Why “Racking” Matters)

OC lots rarely sit flat. Stepping stock panels every eight feet creates a toothy horizon that looks cheap and leaves wedge gaps at the bottom. Racking solves it: the panel rail angles to track grade, bottoms follow the land cleanly, and top lines read straight from the street. That’s the difference between a DIY look and a professional backyard fence installation that photographs well and keeps pets in without infill strips. Pros will note racking in the submittal, show locations where stepping is intentional (e.g., façade wants tiers), and dimension post centers to maintain reveal consistency. It’s a line item on paper—and the reason the finished fence looks like it belongs.

Quick Bid Triage You Can Do in 60 Seconds

Open the proposal and search for: post size & depth, hardware metals, finish system, racking vs. stepping, gate construction, wind assumptions, and HOA/permit sequencing. If two or more are missing, that bid is guessing. If all are present—and there are three recent jobs within five miles of your address with pass dates—you’re talking to fence installers who understand Orange County, not just fences in general.

Ergonomics, Safety, and Neighbor Etiquette That Make Fences Easy to Live With

Good fence installers don’t just drop panels and bounce—they design for how people actually use a property in Orange County. That means side-yard gates wide enough for bins (40–48″), latch heights that meet pool-barrier code but don’t require wrist yoga, return wings that preserve corner visibility so you don’t get red-tagged in Costa Mesa or Tustin, and panel layouts that rack to grade so pets don’t find wedge gaps. On coastal streets in Newport, Huntington, and Laguna, they also plan around salt and morning marine layer: stainless or HDG hardware, isolation at dissimilar-metal contacts, and finishes that breathe if you insist on wood accents. Inland in Yorba Linda, Mission Viejo, and Anaheim Hills, they size posts and rails for wind, add mid-rails where kids and dogs lean, and overbuild hinge posts so gates don’t twist the first Santa Ana. This is the difference between residential fence installation that fades into daily life and a fence you babysit.

Lighting and Sightlines After Dark (So You Don’t Annoy the Block)

Nighttime usability is part of the spec. Low, warm lighting aimed at the latch and address plate beats a blinding flood that screams “facility.” On west-facing lots in Newport Coast or San Clemente, installers angle photo-eyes and choose matte finishes that won’t glare at sunset. For backyard fence installation, subtle path lighting by side gates keeps strollers and bins from clipping posts; for corner lots, taper heights or use open upper bands near the visibility triangle so drivers aren’t guessing. Done right, your fence reads intentional at night—guiding, not glaring.

Dogs, Pools, and City-by-City Quirks

Pool yards: self-closing/self-latching hardware, latch heights set in writing on the packet, and swing away from the pool—non-negotiable across OC. Dog pressure points: mid-rails at push height, compression latches that don’t rattle, and board-on-board or T&G when “privacy fence installation near me” also means “bark control.” Older Santa Ana/Costa Mesa parcels: expect surprise utilities; pros probe and set gravel collars or metal bases so wood isn’t wicking at grade. Irvine/Lake Forest HOAs: color chips and precedent photos get you through the first review; show them and you save weeks.

Maintenance Calendar & Lifespan: Plan It Once, Keep It Boring

A fence that still looks premium after three summers had a maintenance plan from day one. Pros hand you a calendar keyed to your ZIP: rinse cadence, hardware checks, and finish cycles matched to sun, wind, and salt—not a generic “see you never.” Coastal perimeters bias aluminum or vinyl for low upkeep; targeted wood runs get cap-and-trim to shed water, ground clearance to stop wicking, and breathable penetrating oils on a real schedule. Inland, where UV and wind carry the day, fence installers tighten the structure—deeper posts, tighter spacing, mid-rails—and you just oil less often and tune gates after heat swings. This is how residential fence installation becomes quiet infrastructure instead of a hobby.

Coastal Routine (Newport / Huntington / Laguna)

Quarterly quick rinse on metal faces and hardware, lens wipe on any safety/photo eyes if you’ve got gated entries, and a fastener walk-down on exposed faces once a year. Wood accents: spot oil sun-blasted sections as needed; full re-oil 12–18 months. Keep irrigation off metal—overspray is silent death. Expect stainless fasteners and AAMA 2604/2605 powder on metal to pay for themselves in non-events.

Inland Routine (Irvine / Lake Forest / Yorba Linda / Anaheim Hills)

Re-oil wood 18–24 months with UV blockers, check hinge tension after the first big Santa Ana, and walk tall privacy runs annually to catch early rail belly. For composite/vinyl, hose down a couple times a year and confirm reinforced rails are holding line. Gates get a quick hinge/latch tune at season changes. Small, predictable touches—no rescues.

Design Your Ideal Fence & Gates Today!

Bring your vision to life with premium aluminum fencing, custom gates, and modern cladding solutions crafted to elevate any property.

Schedule A ConsultationWarranties, Specs, and Paperwork That Actually Protect You

Paper protects projects. If a bid from fence installers doesn’t name post section and spacing, footing depth and mix by wind zone, hardware metals (stainless/HDG by distance to coast), finish system (AAMA 2604/2605 on metal; breathable oil on wood), slope strategy (rack vs. step), and gate construction (framed leaf + diagonal brace + adjustable hinges + compression latch), it’s not a spec—it’s a hope. Tie the warranty to those lines: post/performance by zone, corrosion coverage within X miles of the coast (contingent on stainless/HDG), and a 30–90 day tune-up in writing so you’re not paying to fix settlement. For backyard fence installation, include pool-latch heights and swing direction right on the drawing; for corner lots, draw the visibility triangles. When it’s in ink, inspectors pass and HOAs nod.

Clauses That Matter (and the Fluff You Can Ignore)

Matters: corrosion strategy, wind assumptions, racking on slope, specific hardware models, finish codes, and inspection sequencing (hole photos before pour where required). Fluff: “lifetime materials” without naming the finish system, “workmanship warranty” with no measurable spec, and “color to be selected later” on HOA streets that only approve three tones. Demand the boring lines now; avoid change-order theater later.

Keeping Change Orders in a Box

Ask for allowances where surprises live: stainless upgrades within coastal distance, deeper footing if the inspector calls wind exposure, and utility conflicts on older lots. Pros price the risk on day one and move; tourists “discover” it at your expense. That’s how you keep privacy fence installation near me from turning into permit purgatory and weekend repairs.

Case-Study Patterns: Why the Same Specs Keep Winning in OC

The jobs that age best share DNA. Coastal Newport Heights/CDM: aluminum or vinyl perimeters, stainless hardware, panels racked to steep grades, framed gates that don’t rack when fog meets noon sun. Irvine/Lake Forest: HOA-clean lines, reinforced vinyl or aluminum, underground or clean hardware at front elevations, and side gates at 40–48″ for bins. Yorba Linda/Anaheim Hills: taller privacy runs with real structure—deeper posts, tighter spacing, mid-rails—and gates anchored on oversized hinge posts with compression latches so wind and thermal swing don’t show daylight. These aren’t preferences; they’re the recurring solutions the best fence installers use because OC keeps asking the same physics questions.

Quick Self-Audit Before You Sign

Hold your address against the spec: Does it say rack (not step) on your slope? Name stainless/HDG by coastal distance? State footing depth by wind zone? Define gate framing and hardware? If two answers are “no,” you’re buying a punch list, not a fence. Fix the paper; the field will follow.

Installation Sequencing That Keeps OC Jobs On-Time (and Straight)

Competent fence installers in Orange County don’t start with a post-hole—they start with a site walk that treats your address like a jobsite, not a brochure. Utilities are marked (older Costa Mesa/Santa Ana parcels love surprise lines), setbacks and corner visibility triangles are taped, and the slope is measured in inches over each panel bay so crews can rack panels to grade instead of stair-stepping every eight feet. On the coast (Newport/Huntington/Laguna), corrosion strategy is set before demo—AAMA-rated powder on metal, stainless or HDG hardware, isolation where dissimilar metals touch—and finish work is scheduled around marine layer mornings and hot afternoons so coatings cure correctly. Inland (Irvine/Lake Forest/Yorba Linda/Anaheim Hills), the plan tightens post spacing on tall privacy faces, deepens augers by wind exposure, and stages mid-rails where kids and dogs lean. Rails and picture-frame borders go in only after posts cure to spec; boards follow with consistent reveals; caps and trims shed water; hardware lands last so salt air hasn’t been attacking it in open boxes all week. That’s how residential fence installation holds line, passes first inspection, and doesn’t need a rescue visit by month three.

The Pre-Build Checklist That Prevents Red Tags

Before anyone digs, a good foreman runs the inspector’s punch list on paper: post depth by wind zone, front-plane height caps, pool-barrier latch heights and swing directions where relevant, sidewalk/right-of-way clearances for driveway wings, and documented racking (not stepping) along slope. Coastal packets include enclosure distances to mandate stainless/HDG and AAMA 2604/2605 powder; hillside packets call out drainage paths and any intentional step sections for façade rhythm. If your search started with privacy fence installation near me, this is what makes “approved once” reality instead of hope: drawings that mirror last month’s neighborhood approvals, hardware cut sheets that match field parts, and hole photos ready if your city requires proof before pour.

Daily QC That Keeps Lines Dead-Straight

Professional crews don’t “eyeball it.” They string the entire run, set temporary braces, and run a plumb/level walk each afternoon—torpedo on posts, tape on centers, and a sightline down long elevations to catch ripple before it shows from the street. Hardware stays boxed until the minute it’s installed on coastal jobs; cut stations sit on plywood pads so saws don’t drift; waste bins live at the cut table so offcuts don’t become planter confetti. Gates are built as doors—framed leaf, diagonal brace, adjustable (nylon-lined or greasable) hinges, compression latch—then tuned after the first heat swing. That’s the difference between backyard fence installation that still looks intentional after summer and one that’s already waving in photos.

Gates, Access, and Everyday Use (Where Most Fences Fail First)

If a fence is going to embarrass you, it’ll be at the gate. OC microclimates make lazy gate specs obvious: marine layer swells wood and blooms rust on cheap hardware at the coast; inland wind twists hinge posts that weren’t sized or set deep enough. The fix is discipline. Side-yard gates get clear widths (40–48″) so bins and strollers pass without knuckle-busting; hinge posts get larger footings; leaves are rigid frames with diagonals, not fence boards nailed to fantasy; and the latch is compression-type to pull the meeting stile tight when temps swing 30°F in a day. On corner lots, swing arcs stay out of public right-of-way; on pool yards, self-closing/self-latching hardware hits the exact latch centerline your city enforces. Good fence installers build these rules into the submittal so the inspector just nods and you move on with your life.

Coastal Gate Package That Doesn’t Rust Out

Newport/Huntington/Laguna punish shortcuts. Stainless fasteners and hinges, AAMA 2604/2605 powder on any exposed metal, isolation pads at dissimilar-metal contacts, and ground clearance so wood doesn’t wick. Keep irrigation off faces; put a rinse and lens-wipe cadence in the handover; and specify adjustable hinges so you tune alignment after the first fog-to-sun cycle. Do that and your coastal residential fence installation stays quiet and clean instead of turning into a chemistry lesson by August.

Inland Wind & Slope: Build for Torque, Not Luck

Yorba Linda/Anaheim Hills/Mission Viejo bring gusts and grade. Deeper augers, tighter on-center spacing for tall privacy runs, mid-rails where dogs and kids lean, and compression latches so thermal swings don’t open daylight. On real slopes (San Clemente canyons), sliding driveway wings beat swing leaves that strike grade; pedestrian runs rack to the hillside so bottoms track the land without wedge gaps. This is the adult version of privacy fence installation near me—no drama, no rework, just a fence that behaves.

Final Thoughts: Build for Your Street, Spec for Your Microclimate, and Keep It Boring (That’s the Goal)

If you want fence installers who deliver results in Orange County, stop grading bids by the prettiest rendering and start grading them by the boring lines that make a fence invisible infrastructure: post size and footing depth by wind zone, panels that rack to grade (not stair-step), stainless/HDG hardware chosen by distance to the coast, finish systems that actually survive fog→sun cycles, and gates built as doors with diagonal bracing, adjustable hinges, and compression latches. Coastal parcels in Newport/Huntington/Laguna will eat shortcuts for breakfast; inland pads in Irvine/Lake Forest/Yorba Linda/Anaheim Hills will expose shallow posts, flimsy rails, and strap-hinge gates the first windy week; older Costa Mesa/Santa Ana lots will punish anyone who ignores utilities and drainage. The right crew treats residential fence installation like a system, not an errand: approvals and materials staged before demo, inspections passed the first time because the packet mirrors last month’s approvals, and a handover that lists maintenance by ZIP so your backyard fence installation stays quiet after three summers instead of becoming your Saturday project. That’s how “privacy fence installation near me” turns into a fence you forget—in the best possible way.

Design Your Ideal Fence & Gates Today!

Bring your vision to life with premium aluminum fencing, custom gates, and modern cladding solutions crafted to elevate any property.

Schedule A ConsultationFrequently Asked Questions

Force apples-to-apples: post section & spacing, footing depth/mix by wind zone, hardware metals (stainless/HDG by coastal distance), finish system (AAMA 2604/2605 on metal; breathable oil on wood), slope strategy (rack vs. step), and gate build (framed leaf + diagonal brace + adjustable hinges + compression latch). If two or more are missing, it’s a guess, not a spec.

Coast (Newport/HB/Laguna): aluminum or vinyl perimeters with AAMA-rated powder and stainless fasteners; targeted wood only with cap-and-trim, ground clearance, and breathable oils. Inland (Irvine/Lake Forest/Tustin/Yorba Linda/Anaheim Hills): cedar/redwood over PT posts for warm privacy or aluminum/composite for low upkeep—deeper posts, tighter spacing, UV-stable finishes.

Most “gate problems” are design problems: panel-on-hinge leaves, tiny hinge posts, no diagonal, and latches that don’t pull the meeting stile tight. Proper residential fence installation uses rigid frames, bigger hinge-post footings, adjustable (nylon-lined/greasable) hinges, compression latches, and clearances that don’t plow DG or turf. Result: finger-close forever.

Depends on address and overlay. Pros run approvals/materials in parallel: HOA packet day one, utility locates booked, stainless/marine hardware ordered for coastal jobs, and inspections scheduled to verify holes before pour where required. Install moves fast once approvals land; “two weeks flat” without seeing your site is sales talk.

Coast: quarterly quick rinse on metal, photo-eye/latch lens wipe if gated, spot-oil wood accents, full re-oil 12–18 months. Inland: re-oil wood 18–24 months with UV blockers, hinge/latch tune after first Santa Ana, annual walk for rail belly on tall privacy faces. Vinyl/aluminum mostly need hose-downs and a yearly hardware check. Keep irrigation off faces—overspray is silent death.