Automatic Gate Installation

- By alupost

- Posted on

Table of Contents

Automatic Gate Installation in San Diego: Engineer for Salt, Slope, Wind, and Right-of-Way

San Diego punishes lazy specs: coastal salt in La Jolla, Point Loma, and OB freckles “painted black” steel by August; canyon gusts in Mission Hills, North Park, and Kensington expose flimsy rails and under-sized operators; sloped sidewalks in Pacific Beach and Ocean Beach turn swing arcs into red tags; and short aprons in Clairemont, Hillcrest, and South Park force geometry decisions before aesthetics. If you want automatic-gate-installation that still cycles quietly after three summers, design like an adult: choose the mechanism by driveway physics (apron depth, threshold slope, sight triangles), size posts/rails for span and wind, specify AAMA 2604/2605 powder on aluminum (or duplex on steel) with 316 stainless hardware and isolation at dissimilar metals, and treat the leaf like structure—not décor. Electric driveway gates fail where drawings are vague: arcs that invade public right-of-way, sliders without runback or drainage, ground tracks set into moving pavers, and operators sized by width instead of actual leaf weight plus wind load. Wrap it with the safety stack that inspectors actually check (UL 325/ASTM F2200 photo-eyes at bumper and stroller heights, monitored edges on the leaf/pocket mouth, loops that let vehicles clear sidewalk before motion), and your automatic driveway gates pass once, run quiet, and stop being a weekend hobby.

Geometry First—Apron Depth, Slope, and Sightlines Decide Mechanism (Not Taste)

San Diego picks slide vs. swing for you. Short aprons in PB, OB, and parts of Mid-City make swing arcs cross sidewalk the second a bumper noses up—automatic fail—so sliding wins: tracked if housekeeping/drainage are honest, cantilever if the threshold sees DG, eucalyptus litter, or alley grit. Sloped sidewalks along Mission Hills and North Park kill pretty double-swings that “toe-in/toe-out” and drag; sliders ignore the slope and stay parallel to traffic, which also preserves sightlines at egress on Berry-street curves. When the lot is flat and deep (Carmel Valley, Rancho Bernardo), swing can pencil—if arcs never enter public right-of-way and hinge-line posts/footings are sized for wind and leaf mass. Draw it like cabinetry: curb-to-gate apron depth in inches, threshold slope, runback pocket length/clearance for sliders, or full swing arcs to scale for swings. If a bid can’t show those numbers, it’s guessing with your driveway.

Mechanism & Materials—Slide (Tracked vs. Cantilever) vs. Swing, and What Survives Here

Tracked sliders feel invisible when the surface is controlled: broom-finish or tight pavers with a crowned rail lane and a drain to daylight at the pocket; sealed carriages, stainless rack/chain, and sweep strips that brush fines without becoming a plow. Cantilever sliders are the adult answer where debris is chronic (DG paths in Kensington back alleys, jacaranda litter in North Park, gritty easements in City Heights): oversized posts at proper spacing, sealed carriage bearings, boxed frames with hidden diagonals, and side guides set to control sway without binding at 3 p.m. heat. Swings look classic on deep, flat La Mesa or Scripps lots—build them like doors: deeper hinge-line footings, larger posts, boxed leaves with diagonals, co-axial adjustable (nylon-lined/greasable) hinges, and compression latches so the meeting stile stays tight. Finish chemistry isn’t a style choice: aluminum + AAMA 2604/2605 powder and 316 stainless near spray is the coastal workhorse; steel needs duplex (galvanize + powder) and sealed penetrations or you’re spot-painting by Labor Day. If you add wood/composite inlays for warmth, back-vent and drip-path them, hold off grade, and re-check operator torque—the inlay mass isn’t free.

Power, Low-Voltage, and Enclosures—Quiet Electronics Beat San Diego Weather

Automatic-gate-installation fails more from wiring than mechanics. DC operators need clean power sized to actual trench length and load: conductor gauge chosen with voltage-drop math panel → pedestal → operator (long Carmel Valley driveways and detached garages surprise people), surge protection on the feed, and a shaded NEMA 4/4X enclosure with sealed glands + drip loops so marine layer mornings don’t condense into the board. Low-voltage (loops, photo-eyes, intercom, keypads) rides in separate conduit from power so video/audio stays clean; devices mount where glare won’t blind sensors (west sun along Point Loma corridors) and where drivers can reach without blocking sidewalk (48–54″ pedestal reach on tight OB aprons). Battery backup matters on summer brownouts; soft-start/stop profiles need tuning to your leaf mass so rack/chain don’t chatter; and obstruction forces are set with a human present—not factory defaults—so the system is safe and calm.

Trenching, Conduit, and Voltage Drop—Do the Math or Buy “Mystery” Stalls Later

San Diego’s long setbacks and piecemeal remodels mean power rarely sits where you want it. Trench once with intent: schedule depth/route, separate conduits for power and LV, and print conductor gauge with voltage-drop math on the plan so you’re not starving a DC motor on hot afternoons in Rancho Bernardo. Land the controller in shade (north/east exposures win), choose enclosures that actually seal (NEMA 4/4X on the coast), and use sealed glands with drip loops so marine layer + irrigation overspray don’t cook boards. If you’re pulling new service down the drive, plan loop sawcuts so cars clear sidewalk before motion; if you’re using existing runs, measure end-to-end so the “100 ft” story isn’t actually 160 ft once it winds around beds. This is the difference between electric driveway gates that “sort of” start at 3 p.m. and automatic driveway gates that feel boring—in the best way.

Access & Connectivity—Make the Pedestal Usable at 7 a.m. and 9 p.m.

Wi-Fi at the curb is a lie in stucco canyons; spec access like you’ve lived here. Use a UL-listed controller as the brain and let apps ride shotgun; run a cellular bridge or hardline where signals are trash (OB alleys, Mission Hills slopes); and mount the pedestal where faces aren’t backlit at noon (avoid south/west glare). Video intercoms aim out of headlight/sunset; keypads/prox sit at 48–54″ reach so drivers don’t yoga-pose into traffic; and schedules for trades stop the 7 a.m. chorus of buzzes. Match device finish to the gate powder (matte/low satin) so the stack disappears. Do this once and your automatic-gate-installation works on trash day and date night—no drama, no “try again” taps.

Safety & Code That Pass the First Time (UL 325 / ASTM F2200 Without Hand-Waving)

San Diego inspectors don’t grade on vibes; they want a safety map they can touch, and automatic-gate-installation only feels “done” when the machine protects people, cars, strollers, and pets by design—not by luck. On short aprons in PB/OB and tight slopes in Mission Hills/North Park, your drawing should already prove the gate never invades public right-of-way, places devices where glare won’t blind them at sunset, and keeps kids from reaching through to triggers. The adult stack looks like this: two photo-eye zones (bumper height ~18–24″ outside and stroller height ~36–40″ inside) aimed away from headlight/sunset glare; monitored safety edges on the leading edge of the leaf and the pocket mouth for sliders; tuned obstruction forces with a human standing there (not factory defaults); and loops cut so vehicles clear the sidewalk before the leaf moves. For electric driveway gates on La Jolla and Point Loma slopes, you add soft-start/soft-stop so rack/chain isn’t a hammer, a shaded NEMA 4/4X enclosure with sealed glands + drip loops so marine layer mornings don’t cook boards, and conductor gauge sized with real voltage-drop math panel → pedestal → operator so hot afternoons don’t cause “mystery” reversals. Do that once, in ink, and automatic driveway gates pass in one visit and stop being an inspection hobby.

UL Devices Placed for Real Streets (Not a Warehouse Aisle)

San Diego glare and headlight geometry are different from a catalog diagram. Along west-facing corridors (Point Loma, Ocean Beach), photo-eyes aimed straight across the drive will see sun and cars—rotate them off-axis, hood them if needed, and keep housings out of sprinkler throw so lenses don’t haze. In alley work (North Park, Kensington, City Heights), hold devices inside the line with vandal-resistant housings and blinded screwheads; run low-voltage in its own conduit so intercom audio/video stays clean; and place pedestals at 48–54″ reach so drivers aren’t blocking the sidewalk to punch a code. Sliders get monitored edges at the pocket mouth where fingers want to explore; swings get edges on meeting stiles where crush risk lives; and both get loops tuned so a car clears the walk before motion—printed on the plan with sawcut locations, not “we’ll see onsite.” This is the difference between a safe automatic-gate-installation and a gadget wall.

Manual Today, Automated Tomorrow—Pre-Solve the Safety Map

Half of San Diego says “we’ll automate later,” then trenches through landscaping twice. Don’t. During fence/drive work, set spare conduit (separate LV from power), mark pedestal and enclosure pads in shade, and sketch the future safety plan on the as-built: photo-eye heights/aim notes, edge locations, loop positions, and a note for leaf weight so torque isn’t guessed later. Even if you’re commissioning manual, your electric driveway gates are now pre-approved to become automatic driveway gates without demo, and your first call won’t be to a concrete saw.

Site Prep & Civil Details—Runback, Drainage, and Footings Decide Whether It Works

Most failures in automatic-gate-installation start in the ground, not in the operator. Tracked sliders only feel “invisible” when the threshold is milled honest—broom-finish or tight pavers crowned for a rail seat—and the pocket drains to daylight so PB/OB irrigation fog and winter rain don’t flood bearings. Cantilever sliders only feel “set-and-forget” when posts are oversized and spaced to carry the leaf, guides control sway without binding at 3 p.m. heat, and clearances are drawn like cabinetry so a hot leaf never kisses stucco or meters in Hillcrest alleys. Swings only feel “classic” when hinge-line footings are deeper and wider than your gut says, rails are sized for span so 12–16′ leaves don’t belly in Santa Ana gusts, and the meeting stile closes with a compression latch that ignores a 30°F day/night swing. Add crowned concrete at posts, isolation at dissimilar-metal contacts so you don’t grow tea-stain freckles, and a 12–18″ hardscape standoff so sprinklers don’t haze faces, and the physics turn quiet—exactly what you want from automatic driveway gates in San Diego.

Tracked vs. Cantilever—Drain or Float Based on Debris Reality

If your runback shares ground with DG paths, eucalyptus litter, or alley grit (North Park, Kensington, Golden Hill), tracks become grinders. Float the mass: go cantilever, specify carriage spacing for the span, box the frame with hidden diagonals, and tune guides to hold plane without pinching when aluminum grows after lunch. If your apron is clean (Carmel Valley, Rancho Bernardo), tracked is faster and efficient—just crown a rail lane, spec sealed carriages, add a sweep that brushes fines without plowing, and draw the drain to daylight at the pocket. Either way, write clearances in inches around walls, gas meters, and stucco returns; “we’ll fit it” is how hot leaves scrape at 3 p.m. The adult automatic-gate-installation packet shows those numbers before you sign.

Swing Geometry on Slopes—Toe-In/Toe-Out Math You Can’t Ignore

San Diego sidewalks rarely sit level next to the curb; toe-in/toe-out is how pretty double-swings start grinding by month two. If you’re set on swing (deep La Mesa lots, flat Scripps cul-de-sacs), prove clearance at the worst point: draw arcs to scale, show grade at the hinge line and at the leaf edge, and put the high-point dimension in ink. Upsize hinge posts and footings, box the leaves, use co-axial adjustable hinges (nylon-lined or greasable), and set compression latches so the meeting stile stays quiet through heat cycles. The more slope and the shorter the apron (Pacific Beach, Ocean Beach), the more slide beats swing—physics, not taste—and the faster electric driveway gates become reliable automatic driveway gates instead of a change-order machine.

Design Language That Still Looks Expensive After Three Summers (Proportion, Finish, Wind Logic)

Curb appeal in San Diego is earned with proportion and chemistry, not ornament, and automatic-gate-installation that actually ages well treats the leaf like architecture: boxed frames scaled to the façade, slat rhythms that line up with garage panels or window mullions, picture-frame borders that repeat trim widths, and vented density where the Santa Ana or canyon breeze would otherwise turn the face into a drum. Along La Jolla and Point Loma, salt plus sun exposes lazy finishes—so aluminum with AAMA 2604/2605 powder in matte/low satin (charcoal, bronze, warm gray) beats glossy black that fingerprints by noon and chalks by August; if you insist on steel for mass, duplex it (galvanize + powder) and seal penetrations or you’ll be spot-painting by Labor Day. Mission Hills and North Park lots stack slope and street glare, so automatic driveway gates look cleanest when the top line is dead-level while the bottom follows grade (racked panels on fences, clear threshold geometry on sliders), and swing leaves get boxed + braced so the meeting stile doesn’t open daylight after a 30°F day/night swing. If you add wood or composite inlays for warmth on electric driveway gates, back-vent and drip-path them, hold off grade, and re-run torque math—mass isn’t free—and keep one palette across metal/fence/pedestal so the system disappears instead of reading like a parts bin. The adult aesthetic is quiet and intentional: one rhythm, one sheen, wind relief where wind lives, and powder chemistry that handles coastal air and PB/OB sprinklers without turning the entry into a maintenance hobby.

Slide Facades vs. Swing Presence—Where Each Actually Looks Better (By Block, Not by Brochure)

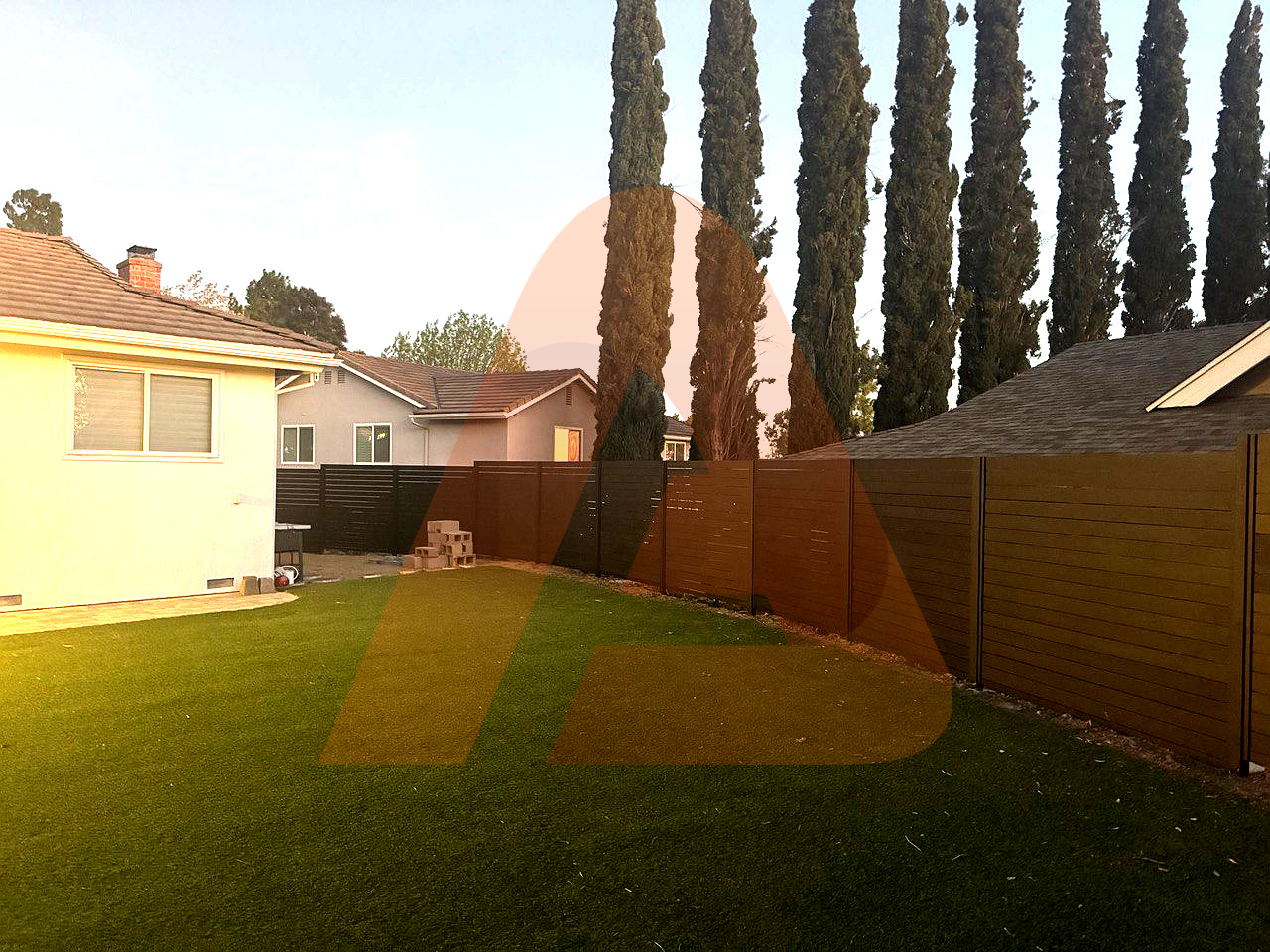

Sliders read modern and parallel to the street; swings read formal and perpendicular—both can look right if you let the block decide. On short Clairemont, PB, and OB aprons, sliders win visually because they never invade sidewalk and they keep the driveway geometry calm; a tracked slider feels “invisible” once you crown a rail lane and drain the pocket to daylight, while a cantilever slider looks deliberate in Kensington and North Park alleys where DG and leaf litter would turn a ground track into a grinder. On deep, flat La Mesa or Scripps cul-de-sacs, a double-swing can frame the approach like a pair of doors—if you draw arcs to scale, upsize hinge-line footings, use co-axial adjustable hinges, and lock the meeting stile with a compression latch so the leaf faces don’t chatter when Santa Anas gust. For canyon-edge Mission Hills or University Heights, use vented faces (narrow horizontals with reveal, staggered boards in a metal picture frame, or perforated/louvered panels inside welded frames) so automatic driveway gates bleed wind instead of fighting it; keep guide pressure honest on sliders so a hot afternoon doesn’t make the leaf kiss stucco, and match pedestal and guide finishes to the gate powder so equipment doesn’t photobomb your frontage. It’s all one idea: geometry first, then a façade that behaves—clean lines, no rattle, no glare, nothing to argue with the street.

Palettes, Sheen, and Night Lighting—Calm at Noon, Useful at 9 p.m.

Color and light are performance choices in automatic-gate-installation, especially on west/south exposures where San Diego sun will ruthlessly shame glossy surfaces and blow out cameras. Keep powders matte/low satin to hide dust and hard-water haze, echo fixture/door hardware so the stack feels deliberate, and avoid mirror sheens that read “facility.” Light the entry like a front door, not a runway: warm 2700–3000K grazers low on the inside face to reveal texture without glare, tight beams on the latch/pedestal zone so keypads and intercoms work without blinding drivers, and zero uplight into lenses. On electric driveway gates with glass/mesh accents, mount fixtures where overspray won’t fog lenses and run low-voltage in separate conduit from power so video/audio stays clean; place the controller enclosure in shade (north/east walls win) with sealed glands and drip loops so morning marine layer doesn’t condense into boards. If you mix materials—aluminum for the wet zones, warm inlays on protected spans—carry one palette and repeat reveals so the hybrid reads designed; then prove usability at night by standing at the curb and actually using the pedestal at 48–54″ reach without blocking the sidewalk. When palette, sheen, and lighting are tuned to block realities, automatic driveway gates look premium without shouting, and they work like appliances on trash day and date night—exactly the brief.

Commissioning, Handover, and the 90-Day Tune—Lock In Quiet Cycles (Not Callbacks)

The last 5% is where automatic-gate-installation wins or bleeds: limits, forces, guides, sensors, wiring sanity, and a paper trail your future self can read. In San Diego, that means you commission when the driveway is hot (3–4 p.m.) so expansion isn’t theoretical; you tune soft-start/soft-stop so rack/chain or arm hardware doesn’t hammer; you set obstruction forces with a human there (not factory defaults); and you prove the safety map in real light—west glare in Point Loma/OB, canyon gusts in Mission Hills/Kensington, sprinkler haze in North Park. For sliders, you confirm the runback pocket clears the leaf at temperature and drains to daylight; for swings, you sight the meeting stile under a string, tension co-axial hinges, and verify the compression latch pulls shut after a 30°F day/night swing. Enclosures live in shade (north/east wall), NEMA 4/4X with sealed glands and drip loops; power conductors are sized with voltage-drop math panel → pedestal → operator; low-voltage rides in a separate conduit so intercom video/audio stays clean. Do that once and your automatic driveway gates feel like an appliance on trash day, not a gadget you babysit.

The Handover Packet That Saves You Years (Write It Like a Map, Not Marketing)

One page for geometry: curb→gate apron depth, threshold slope, chosen mechanism (tracked/cantilever slide or swing) drawn to scale with runback pocket or swing arcs, and final leaf weight in pounds so torque isn’t guessed later. One page for electronics: operator model/firmware, soft-start/stop times, obstruction force numbers, limit targets, surge protection, battery install date, and a wiring diagram with conductor gauges and actual trench lengths (panel → pedestal → operator). One page for safety: photo-eye heights (bumper ~18–24″ outside, stroller ~36–40″ inside) with aim notes away from headlight/sunset glare, monitored edge locations (leading edge + pocket mouth on sliders, meeting stiles on swings), and loop sawcuts positioned so vehicles clear sidewalk before motion—UL 325/ASTM F2200 all in ink. One page for materials/finish: AAMA 2604/2605 powder codes on aluminum or duplex spec on steel, 316 stainless hardware on coastal stretches, isolation pads where stainless meets coated metals, and gasket/weep callouts so water leaves parts, not lives in them. Add maintenance cadence by neighborhood reality—PB/OB rinse + pocket flush, Mission Hills wind checks, La Jolla salt wipe-downs—and your electric driveway gates stay boring (perfect) long after the truck leaves.

First 90 Days—Diagnostics & Tuning That Prevent Service Calls (San Diego Checklist)

Week 1: cycle at noon and at dusk; listen for chatter at the pocket (grit = flush/drain), watch photo-eyes in west glare (hood/rotate if they blink), and verify soft-stop isn’t slamming a hot rack. Week 3 (after first heat wave in La Mesa/Scripps): back guide pressure off a hair on sliders if thermal growth starts to sing; re-tension swing hinges and confirm compression latch still pulls the stile tight; measure line voltage at the operator under start load—if it sags, you undersized conductors for the real run. Week 6 (first coastal fog set in La Jolla/Point Loma): open the NEMA 4/4X box, check for condensation, confirm drip loops and glands are doing their job, wipe lenses, and re-aim eyes if sunrise glare found them. Week 12: re-check obstruction forces with a human present, confirm limits didn’t drift, log any torque changes after wood/composite inlay movement, and tape updated numbers inside the enclosure. If the run lives in DG/leaf country (Kensington, North Park), admit reality and switch a tracked spec that’s turning into a grinder to cantilever at the next service—housekeeping isn’t going to change. This is adult automatic-gate-installation: tiny adjustments, written once, that keep automatic driveway gates quiet through San Diego heat, salt, slope, and wind.

Retrofits & Replacements—Turn Old San Diego Gates Into Quiet, Compliant Machines

Most jobs in San Diego aren’t new builds; they’re creaky double-swings that scrape PB sidewalks, rusted tube frames in Point Loma that tea-stain stucco, or alley pivots in North Park that block right-of-way. The adult way to handle automatic-gate-installation on a retrofit is to stop guessing and measure the driveway physics first: curb→gate apron depth in inches, threshold slope across the opening, sight triangles at egress, and the real debris profile (DG, eucalyptus litter, alley grit). If a swing arc will ever enter public right-of-way, you’re done—convert to a slider; if the ground track would live under leaf drop or DG, jump straight to cantilever; if the apron is flat and deep (La Mesa/Scripps cul-de-sacs), a swing can stay—but you box the leaves, upsize hinge-line footings, use co-axial adjustable hinges, and lock the meeting stile with a compression latch so it doesn’t chatter after a 30°F day/night swing. Faces get upgraded from “painted black” to aluminum with AAMA 2604/2605 powder (or duplex steel) plus 316 stainless hardware and isolation at dissimilar metals so you don’t grow tea-stain freckles by August in La Jolla and OB; wood/composite inlays are back-vented, held off grade, and accounted for in torque because mass isn’t free. Power is fixed once, not three times: conductor gauge sized with voltage-drop math panel → pedestal → operator; low-voltage in its own conduit so intercom audio/video stay clean; shaded NEMA 4/4X enclosure with sealed glands and drip loops so marine layer mornings don’t cook boards. Wrap it with a UL 325/ASTM F2200 map (photo-eyes at bumper and stroller heights, monitored edges on the leaf and pocket mouth, loops that let cars clear the sidewalk before motion) and the “mystery stalls” and inspector callbacks vanish. That’s how electric driveway gates become boring (perfect) automatic driveway gates on San Diego streets without rebuilding the whole frontage.

Salvage vs. Replace—Decide With a Tape, a Wrench, and Physics (Not Sentiment)

Keep posts only if they’re plumb under string, don’t pump water, and actually size to span and wind; 1990s pipe-in-concrete won’t carry a 14–16′ slider without belly. Reuse ground tracks only when the threshold is a single plane you can crown toward a daylight drain; if pavers wander or DG drifts (Kensington, Golden Hill), stop pretending housekeeping will save you and float the leaf on a cantilever with oversized posts, sealed carriages, and side guides set to hold plane without pinching at 3 p.m. heat. Preserve wiring only if the measured end-to-end run meets voltage-drop math under start load; if line-to-line sags at the operator, pull new conductors now and stop paying for “mystery” reversals later. Any salvage plan still prints the numbers in ink: apron depth, slope, runback length/clearances, carriage spacing, guide geometry, leaf weight, operator torque/duty, AAMA powder or duplex spec, stainless grade, isolation locations, and UL device heights/aim notes. If a retrofit bid can’t show those lines, it’s guessing with your driveway and selling you change orders.

“Manual Today, Automated Tomorrow”—Prewire the Upgrade So You Don’t Demo Later

Half the city says “we’ll automate next year” and then trenches through landscaping twice. During fence work, lay the bones for automatic-gate-installation even if you’re commissioning manual: separate conduits for power and low-voltage, conductor gauge printed with voltage-drop math for the actual trench length, a shaded NEMA 4/4X pad for the controller, and a sketched safety map that will pass in one shot—photo-eyes at ~18–24″ (bumper) and ~36–40″ (stroller) aimed out of headlight/sunset glare, monitored edges on the leading edge and (for sliders) the pocket mouth, and loop sawcuts placed so vehicles clear the sidewalk before motion. Label leaf weight on the as-built so torque isn’t guessed when you add the operator; place the pedestal at 48–54″ reach so drivers don’t block the sidewalk; match device finishes to the gate powder (matte/low satin) so the stack disappears. Done this way, your “later” upgrade from electric driveway gates to fully automatic driveway gates is a one-day commission, not a demolition.

Pricing & Bid Reality for Automatic Gate Installation in San Diego (Apples-to-Apples, Not Hopes)

Sticker shock is normal on the coast; change-order shock is optional. In San Diego, automatic-gate-installation prices swing on geometry (apron depth, threshold slope, right-of-way), mechanism (tracked slide vs. cantilever vs. swing), finish chemistry that survives salt (AAMA 2604/2605 on aluminum, duplex on steel), operator torque sized to leaf weight + wind, the safety stack that actually passes UL 325/ASTM F2200 in PB/OB sightlines, and trenching distance from panel → pedestal → operator with voltage-drop math. Cheap bids hide the physics—no runback or swing arcs drawn to scale, no drainage at the slider pocket, ground track proposed on DG alleys in North Park, operators picked by width instead of mass, glossy “painted black” metal that freckles by August in La Jolla/Point Loma, and zero plan for glare on photo-eyes. Use the ranges below to sanity-check electric driveway gates and automatic driveway gates quotes; these assume boxed frames, real powder/pretreat, stainless hardware with isolation, UL safety devices, separate LV/power conduits, and a commissioning + 90-day tune that makes the machine quiet in July heat.

| Scope (San Diego typical) | Installed Range | When It Moves | Main Cost Drivers | Notes |

|---|---|---|---|---|

| Tracked Sliding Gate 12–16′ (manual) | $4,800 – $9,200 | + for pocket drainage, paving repair | Frame section, rail seat, sealed carriages | Great on clean aprons (Carmel Valley/RB); crown a rail lane + drain to daylight |

| Cantilever Sliding Gate 12–16′ (manual) | $7,800 – $13,800 | + for long spans/tight posts | Post section/spacing, carriage set, stiffness | Best for DG/leaf-litter alleys (Kensington, North Park, City Heights) |

| Double-Swing 12–14′ (manual) | $4,200 – $8,900 | + with slope or deeper hinge footings | Hinge-line footings, post size, boxed leaf | Only on deep, flat lots (La Mesa/Scripps); arcs must never enter public ROW |

| Automation Package (DC operator + battery) | $2,900 – $6,900 | + for heavy faces/wind loads | Leaf weight, torque/duty, soft-start/stop | Size to mass + wind, not width; tune obstruction forces with a human present |

| UL 325 / ASTM F2200 Safety Stack | $900 – $2,400 | + long pockets/extra edges | Photo-eyes (2 zones), monitored edges, loops | Bumper (~18–24″) + stroller (~36–40″) heights; loops clear sidewalk before motion |

| Access Pedestal + Keypad/Prox/Video | $750 – $2,200 | + cellular bridge/hardline | Device mix, vandal housings, cabling | Wi-Fi dies at curbs; stucco kills signal—plan connectivity, not hope |

| Power & Low-Voltage Trenching | $18 – $45 / ft | + under driveways/roots | Surface type, conduit count, routes | Print conductor gauge with voltage-drop math; separate LV from power |

| Runback Pocket & Drainage (tracked) | $650 – $2,000 | + linear drain or daylight discharge | Excavation, drain hardware, discharge | Stops PB/OB irrigation + storm wash from flooding bearings |

| Finish Upgrade (AAMA 2605 powder) | $350 – $1,100 | + complex palettes | Chemistry, pretreat, color | Worth it for La Jolla/Point Loma salt + inland UV; matte/low satin only |

| Coastal Hardware Upgrade (316 SS + isolation) | $6 – $14 / lf or $180 – $420 / gate | + heavy spray zones | Fastener grade, isolation pads | Prevents tea-stain where stainless touches coated aluminum/steel |

| Wood/Composite Inlays (per 12–16′ leaf) | $900 – $2,800 | + operator upsizing | Back-venting, mass, fastening | Add warmth; recheck torque and balance; hold off grade, drip-path |

| Permits / HOA / Basic Engineering | $600 – $1,900 | + strict tracts | Submittal depth, precedent sheets | First-pass packets save weeks in Mission Hills/Kensington HOAs |

| Demolition & Haul-Away (old gates/footings) | $700 – $1,800 | + hidden concrete/rebar | Access, surprises, corrosion | Old “painted black” steel hides anchors; budget time, not just tonnage |

| Commissioning & 90-Day Tune | $280 – $680 | + complex safety maps | Force settings, limits, guide pressure | Re-tension after first heat wave; tape settings inside enclosure |

How to Compare Bids in 90 Seconds (San Diego Filter That Actually Works)

Force every proposal to write the physics down: curb→gate apron depth, threshold slope in inches, chosen mechanism (automatic driveway gates slide tracked/cantilever or swing) with runback pocket or swing arcs drawn to scale, and the leaf weight in pounds so operator torque isn’t guessed. Finishes are chemistry in ink (AAMA 2604/2605 on aluminum; duplex on steel), hardware metals by zone (316 SS on the coast) with isolation where stainless touches coated metal, enclosure rating/location (NEMA 4/4X, shade), and conductor gauge with voltage-drop math for the actual trench length panel → pedestal → operator (LV in separate conduit). UL map shows photo-eyes at bumper and stroller heights aimed out of headlight/sunset glare, monitored edges on the leaf and (for sliders) the pocket mouth, and loop sawcuts that let a car clear the sidewalk before motion. Commissioning is a line item—soft-start/stop dialed, obstruction forces set with a human present, limits printed and taped inside the box. If a bid dodges any of those lines, it’s not cheaper—it’s unfinished.

Red Flags That Predict Change Orders (Walk Away, No Regrets)

“Painted black” with no AAMA code; operators chosen by opening width, not mass + wind; no runback or pocket drainage on a tracked slider; ground track proposed for DG/leaf-litter alleys in North Park/Kensington; swing arcs that will invade sidewalk on short PB/OB aprons; photo-eyes mounted at random heights facing west glare; stainless fasteners touching coated aluminum/steel with no isolation (hello tea-stain); one conduit for power + LV; Wi-Fi-only access at the curb in stucco canyons; and a “we’ll tune it later” approach to obstruction forces. That’s how automatic-gate-installation turns into a weekend hobby. Hire the crew that writes the boring stuff in ink—their electric driveway gates run quiet on day one and still do after the first Santa Ana and the first marine layer.

Design Your Ideal Fence & Gates Today!

Bring your vision to life with premium aluminum fencing, custom gates, and modern cladding solutions crafted to elevate any property.

Schedule A ConsultationApprovals, Permits, and Right-of-Way Reality in San Diego (Pass Once, Build Once)

San Diego signs off on automatic-gate-installation when the packet reads like engineering, not vibes: a to-scale site plan that shows curb-to-gate apron depth in inches, threshold slope across the opening, and the chosen mechanism drawn to scale—runback pocket + drainage for sliders (tracked) or carriage/guide geometry for cantilever, or full swing arcs that prove they never cross public right-of-way. On short aprons in PB/OB and slopey Mission Hills/North Park fronts, you make the geometry do the talking so there’s no “trust us” at the counter; on La Jolla and Point Loma blocks inside coastal overlays you also call the finish chemistry in ink (AAMA 2604/2605 on aluminum or duplex on steel), list stainless grade where salt lives, and show isolation where stainless meets coated metals so reviewers don’t picture tea-stain within a season. Egress sightlines get dimensioned like adults: driveway visibility triangles labeled, upper-third density tapered where sight cones pinch, and gate faces vented in wind corridors so inspectors aren’t inheriting a sail. The safety map sits on page one, not buried: photo-eyes at bumper (~18–24″) and stroller (~36–40″) heights aimed out of headlight/sunset glare, monitored edges on the leading edge (and pocket mouth for sliders), and loops cut so vehicles clear the sidewalk before motion—exactly how automatic driveway gates earn a first-pass sign-off. Power and low-voltage are separated on the drawing with conductor gauge sized by voltage-drop math panel → pedestal → operator, the enclosure is pinned to shade (NEMA 4/4X) with sealed glands + drip loops, and the leaf weight is written so operator torque isn’t guessed. Put those boring lines in ink and your electric driveway gates go from submittal to install without the “come back with real drawings” loop.

HOA/ARC Submittals That Don’t Neuter the Design (Mission Hills, Kensington, La Jolla)

Committees in older tracts and canyon neighborhoods hate clutter and glare, not gates. Give them elevations that align slat rhythm to garage panels or window mullions, picture-frame borders that echo trim widths, and matte/low-satin palettes that won’t flash at noon. For automatic-gate-installation on Spanish/Mid-Century elevations, note vented faces (narrow horizontals with reveal, staggered boards in an aluminum picture frame, or perforated/louvered infill) so wind bleeds and the façade doesn’t “drum” in Santa Ana gusts; for coastal lots, promise (and draw) back-vented wood/composite inlays only where they’re protected, with the increased leaf mass rolled into the operator sizing. Label your pedestal at 48–54″ reach so drivers don’t block sidewalk, match device finishes to the gate powder so equipment disappears, and include two photo sheets of nearby approvals—precedent makes ARCs say yes faster. The net: you keep the architecture intact while proving automatic driveway gates won’t glare, rattle, or invade public space.

Encroachments, Sight Triangles, and Coastal Overlays—The “Gotchas” You Solve on Paper

San Diego’s fastest project-killers are avoidable: swing arcs that nick sidewalk on PB/OB aprons; tracked sliders without a drain to daylight at the runback pocket; cantilevers drawn without carriage spacing or hot-day clearances to stucco and meters in Hillcrest alleys; photo-eyes aimed straight into west sun along Point Loma corridors; and “painted black” metal in La Jolla salt with no AAMA code or stainless isolation. Solve them before the counter visit: show swing arcs that live entirely inside the parcel or pick slide and be done; crown a rail lane and draw the drain path if tracked, or float the leaf on a cantilever when DG/leaf litter is a lifestyle; dimension pocket/guide clearances for a hot leaf so it can’t kiss masonry at 3 p.m.; rotate/hood photo-eyes out of glare; and write your chemistry—AAMA 2604/2605 on aluminum or duplex on steel—plus 316 stainless at the coast with isolation at dissimilar contacts. Tie it together with loops placed so a car clears the sidewalk before motion and a shaded NEMA 4/4X enclosure that keeps marine layer out of boards. Do that, and your automatic-gate-installation packet passes once, your crew builds once, and your electric driveway gates behave like infrastructure instead of a project you babysit.

Access, Connectivity, and Daily Flow—Build the Gate Around How You Actually Live

Pretty is cheap; usable is rare. In San Diego, automatic-gate-installation that feels invisible at 7 a.m. on trash day and 9 p.m. after dinner is about access geometry and signals, not app logos. Start with reach and glare: pedestals land where a driver can roll down the window and hit keypad/prox at 48–54″ without stretching into Mission Hills traffic, faces aim out of west/south sun so Point Loma/OB glare doesn’t blind a camera or cook a screen, and housings sit outside sprinkler throw (hard-water film is a slow death). Next is connectivity that survives stucco canyons and alley RF noise: treat the UL-listed controller as the brain and anything “smart” as a passenger; run a hardline or cellular bridge when curb Wi-Fi is fantasy; keep low-voltage in its own conduit so video/audio stays clean; and put the enclosure in shade (NEMA 4/4X, sealed glands, drip loops) so marine layer mornings don’t condense into boards. Then map people flow, not just bumpers: a quiet pedestrian gate on the desire path with a self-closing closer and shielded latch so kids can’t reach through; lockout windows for trades so Kensington/North Park crews don’t buzz you at dawn; courier logic that opens only the parcel slot or pedestrian leaf, not the driveway. Finally, write all of it down—device heights, cable routes, voltage-drop math panel → pedestal → operator, photo-eye positions at bumper (~18–24″) and stroller (~36–40″) heights, monitored edges at the leaf and pocket mouth for sliders—because electric driveway gates fail when “we’ll figure it out onsite” meets San Diego glare, slope, and salt. Do the boring access math now and your automatic driveway gates become a tool you stop thinking about, which is the point.

Trash Day, Trades, and Deliveries—Schedules, Codes, and Fail-Safes That Don’t Back Up the Street

San Diego lanes are tight; your neighbors don’t want a queue. Program the pedestal so Tuesday 6–10 a.m. (or your service window) accepts a contractor code that opens only once per entry, logs the event, and times out; pair it with a separate parcel/courier routine that pings your intercom and pops a narrow leaf or parcel hatch instead of running the entire slider. On short OB/PB aprons where a bumper sits near sidewalk, delay vehicle motion until exit loops confirm the car has fully cleared the public way—ink that in your UL map so an inspector can see it. For cleaners and gardeners, set geofenced or time-boxed credentials that expire without your help; for guests, push one-time codes that throttle retry attempts so the pedestal doesn’t turn into a keypad hammer. Backstop the whole stack with a battery-backed DC operator sized to actual leaf weight + wind, a manual release you can reach in the dark, and clear signage that’s not a billboard. This is the difference between automatic-gate-installation that keeps a block calm and one that turns your driveway into a weekly meeting.

Security Without Theater—Quiet Hardware, Honest Lighting, Cameras That See Faces (Not Headlights)

Security that works in San Diego is boring by design. Cameras mount where they see faces in shade, not headlight bloom—tuck them just inside the line, slightly off-axis to the drive, and keep their lenses out of sprinkler throw; use warm, tight beams on latch/pedestal zones and low grazers for wayfinding so OB/Point Loma west sun and Mission Hills glare don’t wash the sensor. Choose compression latches and co-axial adjustable hinges so swing leaves don’t rattle in a Santa Ana, and set guide pressure on sliders so a hot leaf never kisses stucco at 3 p.m. Finish chemistry is part of security because you won’t maintain gear that looks tired: aluminum with AAMA 2604/2605 powder (matte/low satin) plus 316 stainless hardware and isolation at dissimilar contacts keeps the façade calm in La Jolla salt; duplex steel only if you’ll service it; wood/composite inlays only where you can back-vent and drip-path them, then re-run torque—mass isn’t free. Fold all of that into the packet (device heights, sightlines, finish codes, conductor gauges, loop sawcuts that make cars clear the sidewalk before motion), and your automatic driveway gates stop pretending to be a deterrent and start acting like infrastructure: quiet, readable, and always closed when you need them closed.

Power Resilience & Outage Plan—Keep the Gate Moving When SDG&E Blinks

San Diego’s grid is moody: marine-layer mornings, summer AC spikes, Santa Ana events, and the odd PSPS in backcountry feeds mean your automatic-gate-installation needs a resilience plan that isn’t “hope.” Build it in from day one: DC operators with honest amp-hour battery backups sized to the measured leaf weight plus wind drag (not catalog width), conductors chosen by voltage-drop math panel → pedestal → operator for the actual trench length, and a shaded NEMA 4/4X enclosure with sealed glands + drip loops so Point Loma fog doesn’t condense into boards. If your apron is short (PB/OB) or the driveway sits on a slope (Mission Hills/North Park), program exit loops and obstruction logic so a car clears sidewalk before motion even when the system is on battery; print those behaviors in the packet so an inspector can sign without a second visit. For electric driveway gates that live within sight of salt (La Jolla/OB), isolate stainless from coated aluminum/steel so galvanic creep doesn’t eat terminals, and land a surge protector upstream—coastal static + summer lightning is rare but real. This is how automatic driveway gates stay boring during brownouts: power stays clean, logic is predictable, and the machine honors the street.

Solar Assist, Realistic Battery Sizing, and “Trickle vs. Fantasy Off-Grid”

Solar on a gate is a charger, not a generator—treat it that way. In San Diego, one or two modest panels in full sun can keep a DC operator topped off between normal cycles, but only if you size the battery first to your worst day: number of opens/closes, actual leaf mass (weigh it), and wind load at your microclimate (Mission Hills gust ≠ Carmel Valley calm). Write those numbers, then choose a battery bank that gives you the cycles you need for 24–72 hours without line power; size solar to replace that drain over a few good days, not to run the whole system in fog. Mount panels where salt spray won’t sandblast them and where shadows from palms or rooflines won’t halve output by noon; route PV leads in UV-rated conduit, separate from low-voltage signal, and through the same shaded NEMA 4/4X you put the controller in. If you insist on full off-grid at the curb, be honest about panel area and battery volume—it’s a mini power plant, not a sticker. With a right-sized bank plus solar assist, automatic-gate-installation cruises through SDG&E blips without drama and without you babysitting a charger.

Emergency Egress, Knox, and Manual Release That Works for Humans (Not Just Techs)

Outages aren’t the only emergency; fire and med calls care about minutes, not UI. Put the manual release where a normal adult can reach it in the dark, label it plainly, and teach the household to use it—after you confirm the release doesn’t require a gymnastics routine on a sloped PB sidewalk. In the city and county, a Knox® key switch or strobe/optical receiver at the pedestal is standard on many blocks; mount it where engines can actually see/reach it without blocking traffic, match the device finish to your powder so it disappears, and document the circuit so a future tech doesn’t guess. For automatic driveway gates on downhill drives (Kensington/University Heights), bias obstruction forces conservative and verify soft-start/stop so a stalled car isn’t nudged downhill; for sliders, make sure the pocket is clearable by hand when the operator is disengaged—no hidden stops, no hot-day rubs against stucco. And put one boring line in the packet: after an outage, system returns to “closed” with all safety devices live before resuming auto cycles. That’s how electric driveway gates stay safe when the power flickers, the engine siren shows up, or it’s 5 a.m. and you just need to leave.

Maintenance & Lifecycle—Keep the Machine Quiet for Years (Not Months)

The difference between automatic-gate-installation that becomes “set-and-forget” in San Diego and a gate you babysit is a blunt maintenance cadence written for salt, slope, wind, and irrigation. Along La Jolla/Point Loma and OB, salt spray and marine layer will haze powder and creep into fasteners; inland Carmel Valley/RB bakes operators and batteries; Mission Hills/North Park throws canyon gusts and eucalyptus litter into pockets. Treat the leaf like a small machine: rinse faces where sprinklers overshoot; crown and flush tracked pockets to daylight so bearings aren’t swimming; back-vent any wood/composite inlays and re-check torque because mass isn’t free; keep 316 stainless isolated anywhere it touches coated aluminum/steel so tea-stain never starts; verify soft-start/stop so rack/chain or arms don’t hammer at the ends; and measure voltage at the operator under start load once a year—the DC motor on electric driveway gates will tell you if conductors are undersized or a splice went dumb. Batteries are consumables (2–4 years coastal, 3–5 inland), surge protection isn’t optional near the bluff, and enclosure seals/glands only work if they’re actually seated after a contractor’s last visit. Do the boring checklist on schedule and your automatic driveway gates stay what they should be: invisible infrastructure on trash day and date night.

Seasonal Checklist by Microclimate (Coast, Canyon, Inland—Real San Diego)

Coast (La Jolla, Point Loma, OB): monthly hose/squeegee of faces; quarterly pro clean if you run dark matte powders or any glass; wipe photo-eye lenses; confirm shoe/pocket drains move water to daylight; open the NEMA 4/4X box every change of season—look for condensation rings, confirm drip loops and glands are tight, and re-seat desiccant. Canyon/wind (Mission Hills, North Park, Kensington): after first Santa Ana, cycle a dozen times and listen—back guide pressure off a hair if sliders start to sing at 3 p.m., verify compression latches on swings still pull the meeting stile shut, and check that vented faces (narrow horizontals/louvers/perf) aren’t choked by spider silk and leaf litter. Inland heat (Carmel Valley, RB, La Mesa/Scripps): in July/August, measure line-to-line voltage at the operator while it starts—if it sags, your conductor gauge or splices are lying; re-tune soft-start/stop so a hot rack/arm doesn’t slap; crack the enclosure in the shade and check board temps and battery health. Everywhere: keep irrigation throws ending at a 12–18″ hardscape strip, not at the face; confirm loops still see cars so the leaf waits until the sidewalk is clear; and re-aim photo-eyes that wander into west glare. This is automatic-gate-installation maintenance written for the block you live on, not a generic warranty card.

Service Contracts, Spares, and Data You Actually Use (So Issues Don’t Escalate)

If you don’t want Saturday surprises, write a light service plan: two inspections/year coast, one inland—operator firmware check, limits/force re-verify with a human present, guide pressure set hot, voltage-drop audit recorded, pocket/drain flush if tracked, carriage inspection if cantilever, hinge lubrication where spec allows (co-axial nylon-lined/greasable only), and a battery load test. Keep a tiny spares kit on the shelf (pair of photo-eyes, a monitored edge strip, a latch kit, lens hoods, isolation pads, stainless hardware pack, spare conduit glands, and a printed one-page wiring diagram). Log cycle counts or calendar time for preventive battery swaps (coast: 24–36 months; inland: 36–48) and tape dates/settings inside the enclosure so the next tech isn’t guessing. For homes that live on deliveries, add a quarterly pedestal test: keypad/reader codes, intercom clarity at noon sun, and camera aim slightly off-axis so headlights don’t blind sensors. These small habits keep electric driveway gates and fully automatic driveway gates boring—quiet cycles, clean passes, no callbacks—exactly why you installed them.

Design Your Ideal Fence & Gates Today!

Bring your vision to life with premium aluminum fencing, custom gates, and modern cladding solutions crafted to elevate any property.

Schedule A ConsultationReal San Diego Case Studies—What Actually Works on Salt, Slope, and Short Aprons

Pretty drawings die fast on San Diego streets; the installs that stick are the ones that start with driveway physics and end with an operator sized to real leaf weight plus wind, not catalog width. In La Jolla and Point Loma, marine layer + afternoon sun punish “painted black” tube frames and under-sealed electronics; the builds that still look new after three summers pushed automatic-gate-installation toward aluminum with AAMA 2604/2605 powder in matte/low satin, 316 stainless hardware with isolation where stainless meets coated metal, shaded NEMA 4/4X enclosures with sealed glands + drip loops, and either tracked sliders with pocket drains to daylight or cantilever sliders where sand and leaf litter never stop. Mission Hills and North Park add slope and canyon gusts, which is where sliders shine—parallel to traffic, zero arc into right-of-way, and vented faces (narrow horizontals with reveal or perforated/louver infill inside boxed frames) that bleed wind so the leaf doesn’t “drum” at 3 p.m.; swing only pencils on deep, truly flat approaches, with co-axial adjustable hinges and compression latches so the meeting stile doesn’t chatter after a 30°F day/night swing. Inland in Carmel Valley, RB, La Mesa, and Scripps, the enemy is heat and distance: long trenches starve DC operators unless conductor gauge is chosen with voltage-drop math panel → pedestal → operator, soft-start/stop gets tuned so rack/chain or arms don’t hammer, and battery backup is sized to cycles, not brochures. The through-line for electric driveway gates and fully automatic driveway gates that just work: draw the geometry (apron, slope, runback pocket or swing arcs) to scale, print leaf weight in pounds, pick chemistry for the block you live on, map UL devices for headlight/sunset glare, and separate low-voltage from power so video/audio stays clean. Do that, and the gate becomes invisible—in the correct way.

Point Loma / OB: Salt, West Sun, and Zero Patience for Sidewalk Invaders

A double-swing on a short Ocean Beach apron looked great on Instagram and failed on day one: toe-in/toe-out on a sloped sidewalk and an arc that nicked right-of-way. The adult rebuild was a tracked slider because housekeeping was solvable: we milled a crowned rail lane into broom-finish concrete, set sealed carriages, and detailed a linear drain to daylight at the pocket so marine layer + sprinklers couldn’t flood bearings. The face moved to aluminum with AAMA 2605 matte charcoal over real pretreat; all fasteners jumped to 316 stainless with isolation pads; the enclosure went to a shaded wall in a NEMA 4/4X box with sealed glands and drip loops; and the operator was sized to weighed leaf mass + wind. UL map put photo-eyes at ~20″ (bumper) and ~38″ (stroller) aimed out of west glare, monitored edge at the pocket mouth, and loops cut so a car cleared sidewalk before motion. Result: automatic-gate-installation that passes once and stays quiet—no tea-stain freckles, no 3 p.m. chatter, no sidewalk drama.

Mission Hills / North Park Alleys: Slope, DG, Eucalyptus Litter—Cantilever or Don’t Bother

Ground tracks in DG and leaf drop are grinders, full stop. A North Park alley pivot kept jamming, then a tracked slider inherited the same fate. The fix that stuck was cantilever: oversized posts at proper spacing, sealed carriage bearings, a stiffer boxed aluminum frame with hidden diagonals, side guides set to control sway without pinching at heat, and a pocket envelope drawn like cabinetry so the hot leaf never kissed stucco or meters. Devices stayed inside the line in vandal-resistant housings; low-voltage had its own conduit; the operator enclosure sat in shade; and a cellular bridge backed the UL-listed controller because curb Wi-Fi is a fairy tale in stucco canyons. Finish stayed low-satin AAMA 2604/2605, stainless hardware was isolated, and a quarterly sweep of carriage pockets became the only maintenance. That’s how automatic driveway gates stop being weekend hobbies and turn into boring (perfect) machines on alley lots.

Build Sequencing & Trade Coordination in San Diego—So You Don’t Tear It Up Twice

Most “mystery costs” on automatic-gate-installation jobs aren’t mysteries; they’re sequencing errors where the paver crew sets a beautiful apron, irrigation gets turned on, stucco is patched—and then the gate team shows up and cuts everything to run conduit, set posts, or drain a slider pocket. Fix it in the calendar, not after the saw cuts: survey and utility locates first, trenching and conduits second (separate runs for power and low-voltage from panel → pedestal → operator), footings and sleeves third, then hardscape, then verticals, then electronics, and only then irrigation tune and plantings. On PB/OB and North Park lots where the apron is short and sidewalks slope, lock the mechanism choice (tracked vs. cantilever slide or swing) before any concrete is poured; crown a dedicated rail lane and draw a drain to daylight if you’re going tracked, or widen post/footing pads and the pocket envelope if you’re floating a cantilever so the hot leaf can’t kiss stucco at 3 p.m. In La Jolla and Point Loma, coastal overlays and salt push finish choices earlier: AAMA 2604/2605 powder on aluminum or duplex on steel gets written into the GC spec, 316 stainless fasteners get ordered with isolation pads so nobody swaps in zinc on install day, and the NEMA 4/4X enclosure location is decided where it actually has shade. Mission Hills and Kensington jobs add slope and wind: the concrete sub pours crowned, straight rail seats and deeper hinge-line footings the same week as fence post piers so there’s no cold-joint surprise; the landscaper holds back 12–18″ of hardscape standoff so sprinklers don’t fog faces; and the low-voltage tech lays loops and device conduits before pavers go down. Do this once and your automatic driveway gates look like they’ve always been there; skip it and you’ll be paying twice—once to build, once to fix what the calendar broke.

Concrete, Pavers, and Irrigation—Who Moves First, Who Follows (And What to Put in Ink)

Concrete and pavers don’t “work around it later”—they lock the geometry forever. Before a yard sees a saw cut, the automatic-gate-installation packet needs the boring numbers: curb→gate apron depth in inches, threshold slope, runback pocket length/clearances if tracked, carriage/guide geometry if cantilever, or full swing arcs that prove they never invade public right-of-way. The concrete crew pours crowned pads for tracked rails and guide posts, not perfectly flat ponds; paver crews leave a dead-straight lane for the rail with room for anchors and weeps; and both teams leave the pocket’s drain path open to daylight, not “we’ll drill later.” Irrigation follows after electronics—not before—so rotors don’t live in front of photo-eyes or fog the face; throws end at a hardscape strip, not the gate, and the controller gets a shaded, reachable spot before plantings box it in. North Park alleys with DG and eucalyptus litter? Don’t pour a rail you’ll grind—draw the cantilever and oversize the posts, then make the mason leave honest air around meters and stucco returns so a hot leaf can’t rub. Mission Hills slopes? If a swing must happen, you write hinge pad depth/diameter by height and wind, spec co-axial adjustable hinges and a compression latch, and show the high-point clearance dimension so everyone can see it passes. Lock those things on paper and your electric driveway gates won’t inherit someone else’s pretty mistake.

Inspections, Submittals, and Commissioning Windows—Book Them Like a Critical Path

San Diego inspections get easy when the packet matches dirt, but you still have to schedule them like a build, not a hope. Rough: open holes for posts/guide posts (or hinge pads) with depth/diameter tagged; conduits stubbed (power and low-voltage in separate sleeves); and, if tracked, the crowned rail seat formed with the pocket drain visible. Final: leaf hung and cycling, photo-eyes at bumper (~18–24″) and stroller (~36–40″) heights aimed out of headlight/sunset glare, monitored edges on the leading edge and (for sliders) the pocket mouth, loops cut so vehicles clear sidewalk before motion, and the enclosure mounted in shade (NEMA 4/4X) with sealed glands + drip loops; the finish chemistry (AAMA 2604/2605 on aluminum or duplex on steel) and stainless grade/isolation are printed in ink—inspectors along the coast look. Commissioning isn’t “when we have time”; it’s a hot-afternoon appointment where soft-start/soft-stop is tuned to the actual leaf weight + wind, guide pressure is set so a 3 p.m. leaf doesn’t kiss stucco, and obstruction forces are verified with a human present. Book the 30–90-day tune on the spot—Mission Hills wind, La Jolla salt, and OB glare will show you what to tweak—and tape settings inside the enclosure so the next tech isn’t guessing. Do that, and automatic driveway gates stop being a scheduling story and start being a quiet machine that just works.

Smart Integration & Security—Local-First Control That Works in San Diego (Not Just in the App Store)

Pretty UI won’t save a bad system. For automatic-gate-installation that’s dependable in San Diego’s stucco canyons and foggy coast, treat the UL-listed gate controller as the brain and every “smart” layer as a passenger. That means relays/dry contacts for scenes, door-station integrations that still pass UL 325/ASTM F2200 if the cloud dies, and access rules that live locally (time windows for trades, one-time codes for guests, schedule logic for trash day) whether Wi-Fi behaves or not. In La Jolla/Point Loma marine layer, Wi-Fi at the curb is fantasy—run PoE or a shielded hardline, or use a cellular bridge with real RSSI, then keep all safety devices (photo-eyes at bumper ~18–24″ and stroller ~36–40″, monitored edges at leaf/pocket mouth, exit/entry loops that clear sidewalk before motion) wired back to the controller so electric driveway gates remain safe even if your app sulks. In Mission Hills/North Park slopes, separate low-voltage from power in its own conduit so video intercom audio isn’t trash; in PB/OB west sun, mount cameras and keypads out of glare so faces don’t blow out at noon. Log events on the controller (opens, codes used, faults), size battery backup to leaf weight + wind, and keep the NEMA 4/4X enclosure shaded with sealed glands + drip loops so marine layer doesn’t condense into boards. Do this and your automatic driveway gates act like appliances—local, quiet, predictable—with your phone as convenience, not life support.

Which Smart Stack Plays Nice (HomeKit/Google/Alexa vs. Control4/Crestron)—And What Not to Do

Hook your automatic-gate-installation to the home the adult way: use a UL-listed controller that exposes dry contacts or secure IP endpoints, then let HomeKit/Google/Alexa mirror scenes (arrive/depart, night lock) while the hardware enforces safety. For serious estates in Rancho Bernardo/Carmel Valley, Control4/Crestron/KNX land cleanly if you treat the gate like a door with interlocks: scene opens only when loops say the vehicle has space; pedestrian gate never trips the driveway leaf; “party mode” extends hold-open but never disables photo-eyes/edges. Readers should speak OSDP (encrypted) over RS-485, not plain Wiegand over long curb runs that hum with interference; video intercoms ride PoE back to the rack, not 2.4 GHz scraping at the curb. Never let cloud logic bypass hardware interlocks; never hang a swing/slide on a smart relay alone; and never share the same conduit for power and LV unless you like glitchy intercoms. If you insist on geofencing for electric driveway gates, throttle it: geofence arms a short “ready” window, then a keypad/prox confirms—so a phone in a beach bag doesn’t open the yard from half a block away.

Cyber Hygiene & Daily Ops—Keep Convenience Without Creating a Backdoor

Security here is boring by design. Put the gate gear on its own VLAN, no port-forwarding, VPN only; rotate contractor codes quarterly; rate-limit the pedestal so it can’t be brute-forced; and expire guest codes automatically after your event. In Newport-facing winds or canyon gusts, schedule firmware updates for calm daylight hours and only after backing up the controller config; print the current versions and tape them inside the enclosure next to force/limit settings. Store 30–60 days of access logs locally (not just in an app) so you can answer “who opened at 6:12 a.m.” without begging a cloud; aim cameras slightly off-axis to avoid headlight bloom, and keep lenses out of sprinkler throw. Where salt lives (La Jolla/OB), isolate 316 stainless from coated aluminum/steel at every contact point or you’ll grow tea-stain around readers and hinges; where heat lives (La Mesa/Scripps), check battery health each summer and measure live voltage at operator start so you don’t chase “mystery” reversals that are just drop. Last: teach the manual release in daylight, label it, and confirm it’s reachable on a sloped apron—because automatic driveway gates are only “secure” if humans can exit fast when SDG&E blinks or an engine crew needs through.

Final Thoughts: Spec for Salt, Slope, and Wind—Then Your Gate Becomes Invisible (The Goal)

If you want automatic-gate-installation in San Diego that still feels “new” after three summers, stop treating the gate like décor and spec it like infrastructure. Let driveway physics pick the mechanism first—short PB/OB aprons and sloped sidewalks push you to sliders (tracked with real drainage or cantilever where DG/leaves live), while deep, flat La Mesa or Scripps lots can carry a swing if arcs never cross public right-of-way—and then size posts, rails, and operators to leaf weight plus wind instead of brochure width. Chemistry isn’t optional: aluminum with AAMA 2604/2605 powder and 316 stainless (isolated at dissimilar-metal contacts) survives La Jolla/Point Loma salt; steel only flies duplexed (galvanize + powder) with sealed penetrations; wood/composite inlays need back-venting, drip paths, and torque re-calcs because mass isn’t free. Power and low-voltage ride in separate conduits, conductor gauge is chosen with voltage-drop math panel→pedestal→operator, and the enclosure sits in shade (NEMA 4/4X, sealed glands, drip loops) so marine layer mornings don’t cook boards. Safety is inked, not implied: photo-eyes at bumper and stroller heights aimed out of headlight/sunset glare, monitored edges on the leading edge and pocket mouth, loops that let vehicles clear the sidewalk before motion. Commission at 3–4 p.m. heat, tune soft-start/stop so nothing hammers, and tape settings inside the box; do that once and your electric driveway gates behave like appliances on trash day and date night—quiet, compliant, boring (perfect).

Design Your Ideal Fence & Gates Today!

Bring your vision to life with premium aluminum fencing, custom gates, and modern cladding solutions crafted to elevate any property.

Schedule A ConsultationFrequently Asked Questions

Pick by geometry and debris, not taste. Short aprons and sloped sidewalks in Pacific Beach, Ocean Beach, Mission Hills, and North Park tilt hard toward sliders because swing arcs invade right-of-way and toe-in/toe-out on slope becomes a callback machine. Use tracked sliders on clean, crownable thresholds with pocket drainage to daylight; go cantilever where DG, eucalyptus litter, or alley grit will turn a ground track into a grinder. Save double-swings for deep, flat approaches in La Mesa/Scripps—then box the leaves, upsize hinge-line footings, run co-axial adjustable hinges, and lock the meeting stile with a compression latch so automatic driveway gates don’t chatter after a 30°F day/night swing.

Aluminum + AAMA 2604/2605 architectural powder is the coastal workhorse for automatic-gate-installation; keep the sheen matte/low satin (charcoal/bronze/warm gray) so salt film and fingerprints don’t headline your entry. Hardware near spray zones is 316 stainless, isolated anywhere stainless meets coated aluminum or steel to kill tea-stain freckles. Steel only pencils duplexed (hot-dip galvanize + powder) with sealed penetrations and real weeps; otherwise you’ll be spot-painting by Labor Day. Add wood/composite inlays only where they’re protected; back-vent, hold off grade, and re-run torque because your operator sizes to mass plus wind, not aesthetics.

San Diego inspectors care about physics and UL 325/ASTM F2200 compliance. They’ll verify the gate never enters public right-of-way, that photo-eyes sit at bumper (~18–24″) and stroller (~36–40″) heights aimed out of glare, that monitored edges protect the leading edge (and pocket mouth for sliders), and that exit/entry loops let vehicles clear the sidewalk before motion. They’ll also look for soft-start/stop (no hammering), real enclosure protection (NEMA 4/4X in marine zones), and conductor sizes that won’t starve a DC motor at 3 p.m. heat. Permits/approvals are commonly required where frontage or power work is touched—bring a packet with site plan, arcs/runback drawn to scale, finish chemistry in ink, UL device map, and you pass once.

Sanity bands (installed, typical 12–16′): tracked slider (manual) ~$4.8k–$9.2k; cantilever (manual) ~$7.8k–$13.8k; double-swing (manual) ~$4.2k–$8.9k; automation package with battery ~$2.9k–$6.9k; UL safety stack $0.9k–$2.4k; trenching $18–$45/ft. Creeps hide where physics are missing: no pocket drainage on tracked specs, ground tracks proposed in DG alleys, operators picked by width not leaf weight + wind, glossy “painted black” metal with no AAMA code, photo-eyes aimed into west sun, one conduit shared for power + low-voltage, and Wi-Fi-only curb access in stucco canyons. Force apples-to-apples: apron depth, slope, arcs/runback to scale, leaf weight, finish chemistry, stainless grade + isolation, UL map, conductor gauge with voltage-drop math, commissioning + 90-day tune in writing.

Prewire now. During fence/drive work, run separate conduits for power and low-voltage; print conductor gauge with voltage-drop math for the actual trench length; set a shaded NEMA 4/4X pad for the controller; and sketch the future UL map on the as-built (photo-eyes at bumper/stroller heights, monitored edges, loop sawcuts where a car clears the sidewalk before motion). Place the pedestal at 48–54″ reach so drivers don’t block the sidewalk; match device finishes to gate powder (matte/low satin) so equipment disappears; and write the leaf weight in pounds on the closeout sheet so torque isn’t guessed later. Done right, your upgrade from electric driveway gates to fully automatic driveway gates is a one-day commission—not a demolition.