Aluminum Sliding Gates in San Jose California

- By alupost

- Posted on

Table of Contents

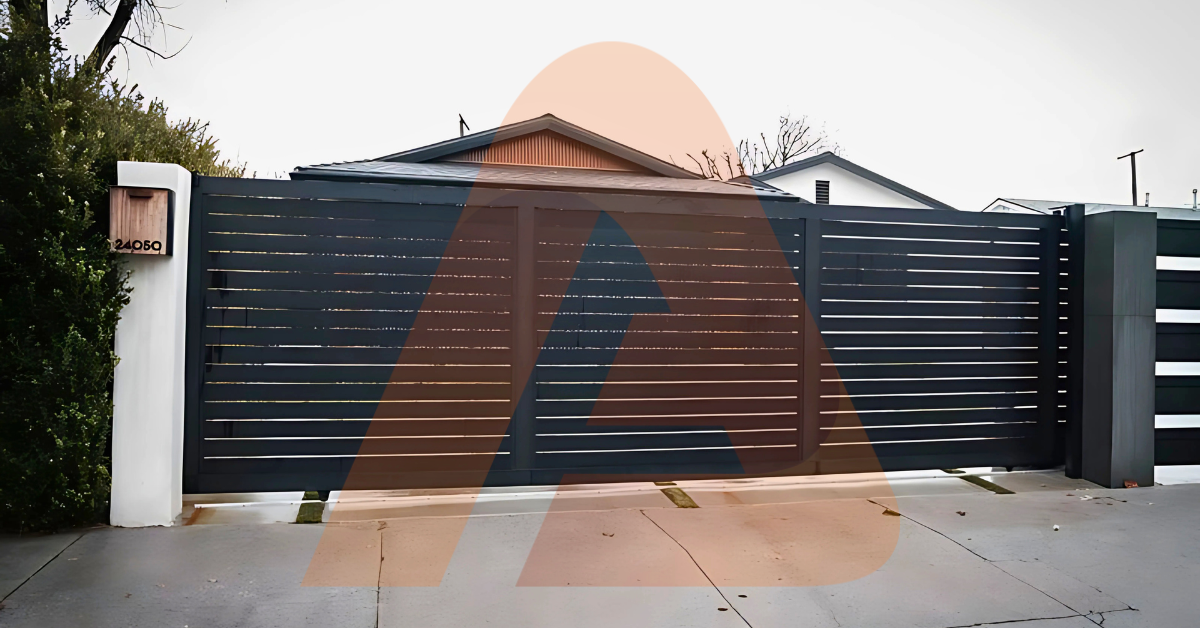

Aluminum Sliding Gates in San Jose: Why Sliders Win on Real Driveways

San Jose driveways are short, sloped, and crowded—garage aprons in Willow Glen and Rose Garden, alley cuts in Japantown and Naglee Park, corridor winds in Almaden and Santa Teresa, expansive clay in Evergreen and Silver Creek—so aluminum-sliding-gates usually beat swing because they stay out of public right-of-way, clear slopes without dragging, and keep sightlines clean at egress. The lighter leaf mass of modern aluminum gates lets DC operators run cooler and quieter in valley heat, and the corrosion profile makes sense next to daily irrigation: AAMA 2604/2605 powder over real pretreat with stainless hardware (and isolation where stainless meets coated aluminum) means no tea-stain freckles by summer. A credible sliding driveway gate installation starts with driveway physics, not brochure mood—apron depth (curb to gate line), slope across the threshold, wind exposure, and pedestrian paths. If the apron’s short or the sidewalk pitches up, you draw a slider with runback or you invite a red tag; if irrigation kisses the face every morning, you spec aluminum and route water away; if corner triangles matter (Berryessa/North Valley), you taper density near the cone. Do that and the leaf moves like infrastructure: one touch, no rattle, no drama—just a quiet horizontal motion that never argues with the street.

Apron, Slope, and Sightlines—Mechanism Chosen by Geometry, Not Taste

San Jose picks your mechanism for you. On short Willow Glen aprons, a swing arc crosses sidewalk the moment someone noses a bumper to the line—automatic fail—so sliding gate installation draws a runback pocket parallel to the curb and shows drainage to daylight; on sloped Cambrian and Alum Rock thresholds, sliders avoid “toe-in/toe-out” swing problems and keep the leaf off concrete; on busy corners in Berryessa or North Valley, an open upper third near the triangle plus a slider that stays parallel to traffic preserves egress visibility without inviting inspectors back. If debris is predictable (leaf litter under jacarandas, DG paths, alley grit), you call cantilever instead of pretending a ground track will stay clean; if the runback is tight, you document pocket clearance or change the façade rhythm to recover inches. This is how aluminum-sliding-gates go from “idea” to a pass-once plan: geometry first, styling later.

Finish and Hardware That Survive Valley Sun and Sprinklers

San Jose isn’t coastal, but UV + hard water + nightly irrigation will age lazy specs fast. Modern aluminum gates take AAMA 2604/2605 architectural powder in matte/low satin (charcoal, bronze, warm gray) over a documented pretreat; hardware is stainless where water lives, with isolation pads at stainless-to-aluminum contacts; penetrations get sealed glands and drip loops so enclosures don’t wick moisture. If you insist on mixed materials (wood inlays for warmth), you back-vent and drip-path so you don’t trap steam against aluminum, and you re-check operator torque because inlays add mass. Put the chemistry and metals in ink on the submittal and your sliding gate installation stays quiet and clean through three summers instead of chalky by July.

Engineering the Slider: Track vs. Cantilever for San Jose Blocks

“Slider” isn’t one thing—it’s tracked or cantilever—and San Jose tells you which lane to use. Tracked wins when you control housekeeping: straight, stable apron grades in Almaden and Santa Teresa where a drain to daylight is easy; cantilever wins where debris is chronic: DG paths in Evergreen, leaf litter in Willow Glen side yards, alley grit in Naglee Park. Either way, aluminum-sliding-gates want a stiff, boxed frame with hidden diagonals, a guide system that prevents sway without binding in heat, and operators sized to real leaf weight plus wind—not catalog optimism. Rails and posts act like structure, not décor: you pick section for span so a 12–16′ leaf doesn’t belly, and you place the controller in shade because valley sun cooks boards. The drawing shows runback or guide post geometry to scale, lists conductor gauge with voltage-drop math if you’re powering today or later, and maps safety even if you’re manual now (photo-eye sightlines, monitored edge pinch points) so upgrades don’t mean demo.

Tracked Sliders—Fast, Efficient, and Honest When You Can Keep the Track Clean

Choose tracked when your surface is predictable and you’ll actually maintain it: broom-finish or pavers with a gentle crown, a linear drain or daylight outlet at the pocket, and a service strip that stays clear of bins and plantings. In sliding gate installation for Rose Garden and Almaden, sealed carriage wheels, stainless rack/chain, and a low-sheen powder keep cycles quiet; you spec sweep strips that brush fines without turning the leaf into a plow, and you keep irrigation throw ending at a hardscape strip so hard water doesn’t haze the face. Voltage-drop math lives on the plan, not in someone’s head, and the operator enclosure sits in shade with sealed glands and drip loops so the first marine-layer morning doesn’t condense inside the box. Done right, tracked sliders feel invisible: they roll, stop soft, and never argue with the sidewalk.

Cantilever Sliders—When Debris, DG, and Alleys Make Tracks a Grinder

If your run lives in DG, under trees, or along a gritty alley, skip the ground rail and carry the leaf: oversized posts at proper spacing, sealed carriage bearings, and a stiffer modern aluminum gates frame that doesn’t belly across long spans. Guides control sway without binding when metal expands at 3 p.m.; pocket faces get matte powder so cameras don’t flare; and the plan calls out clearance to masonry, meters, and trash gates so the floating leaf never kisses anything on a hot day. Cantilever costs more in steel and hardware, but it deletes the single biggest failure mode in San Jose yard life: tracks filled with last night’s landscaping. When the drawing shows post section, carriage spacing, and pocket clearances in inches, your aluminum-sliding-gates behave like infrastructure on day one—and still do after three summers.

Automation, Access, and Safety That Don’t Bite You Later (San Jose Reality, Not Brochure)

If you want aluminum-sliding-gates that behave like infrastructure in San Jose—not a gadget wall—build the automation stack around your driveway physics, your connectivity, and UL 325/ASTM F2200 from day one. That means a DC operator sized to actual leaf weight plus wind load (not catalog optimism), battery backup so Almaden/Santa Teresa brownouts don’t trap cars, and an enclosure living in shade with sealed glands and drip loops so valley temperature swings and morning condensation don’t cook boards. Power isn’t a guess: you run conductor gauge with voltage-drop math on the plan for the real trench length from panel to pedestal to operator, you separate low-voltage from power to keep noise out of video/audio, and you land everything in a NEMA 4/4X or better box because irrigation overspray in Willow Glen/Rose Garden is a silent killer. Access is human first—clean pedestal placement at 48–54″ reach that doesn’t force a driver to block the sidewalk, devices aimed out of glare, and a routine that lets deliveries and trades in without opening the leaf every five minutes. Safety is not optional or “we’ll figure it out”: sliding gate installation has monitored edges on the moving leaf and pocket mouth, photo-eyes at correct heights (car bumper + stroller level) aimed away from headlight/sunset glare, and loops cut where vehicles clear the sidewalk before motion. Draw every sensor, height, and wire path; then the inspector signs once and your modern aluminum gates cycle quietly for years instead of becoming a callback machine.

Access Control That Actually Works on San Jose Streets (Connectivity, Not Wishful Wi-Fi)

Neighborhood Wi-Fi is flaky, alleys are worse, and stucco eats signals—so spec access like you’ve lived here. For aluminum-sliding-gates on short Willow Glen or Rose Garden aprons, use a slim pedestal with keypad + prox + video intercom, run a cellular bridge or hardline backhaul instead of trusting curbside Wi-Fi, and mount the call station where faces aren’t backlit at noon (south/west exposures glare). In Japantown/Naglee Park alleys, keep devices inside the property line with vandal-resistant housings and blinded screwheads; set a contractor code that opens only during defined windows so yard crews stop buzzing you from the street. If you stack smart locks or app-based openers, make them passengers—not pilots—behind a UL-listed controller that still works when the cloud doesn’t. For HOAs in Almaden/Silver Creek, match finish and color (matte/low satin charcoal/bronze) to the gate powder so the pedestal disappears, and keep the runback pocket free of camera views so bugs and lighting don’t trip analytics. This is how sliding gate installation stays usable at 7 a.m. on trash day and 9 p.m. when your router reboots—inputs are redundant, signals are clean, and the pedestal sits where drivers can reach it without yoga.

Safety Map (UL 325/ASTM F2200) You Can Hand an Inspector Without Blushing

Stop hand-waving and put it in ink. San Jose inspectors want to see, for aluminum-sliding-gates, at least two photo-eye zones: outside at bumper height (18–24″) aimed away from car headlight glare, and inside at stroller/kid height (36–40″) to protect walk paths; monitored edges on the leading edge of the leaf and at the pocket entrance to cover pinch points; and exit/entry loops cut so vehicles fully clear the sidewalk before the leaf moves. If wind gusts in Almaden/Santa Teresa cause nuisance reversals, you tune obstruction forces with a human standing there—not factory defaults—and you prove soft-start/soft-stop profiles so the rack/chain doesn’t chatter. Label wire types, conductor gauges, and terminations; show the enclosure rating (NEMA 4/4X in irrigated or mist-prone zones) and the shaded mounting location; and tape a one-pager inside the box with limits, force settings, loop sensitivities, and battery install date. For pocketed tracked sliders, show the drain to daylight and the monitored edge at the pocket mouth; for cantilever, show carriage spacing and guide geometry so sway is controlled without binding at 3 p.m. heat. Do this once and your modern aluminum gates quit being an inspection hobby and start being the quiet, predictable machine you paid for.

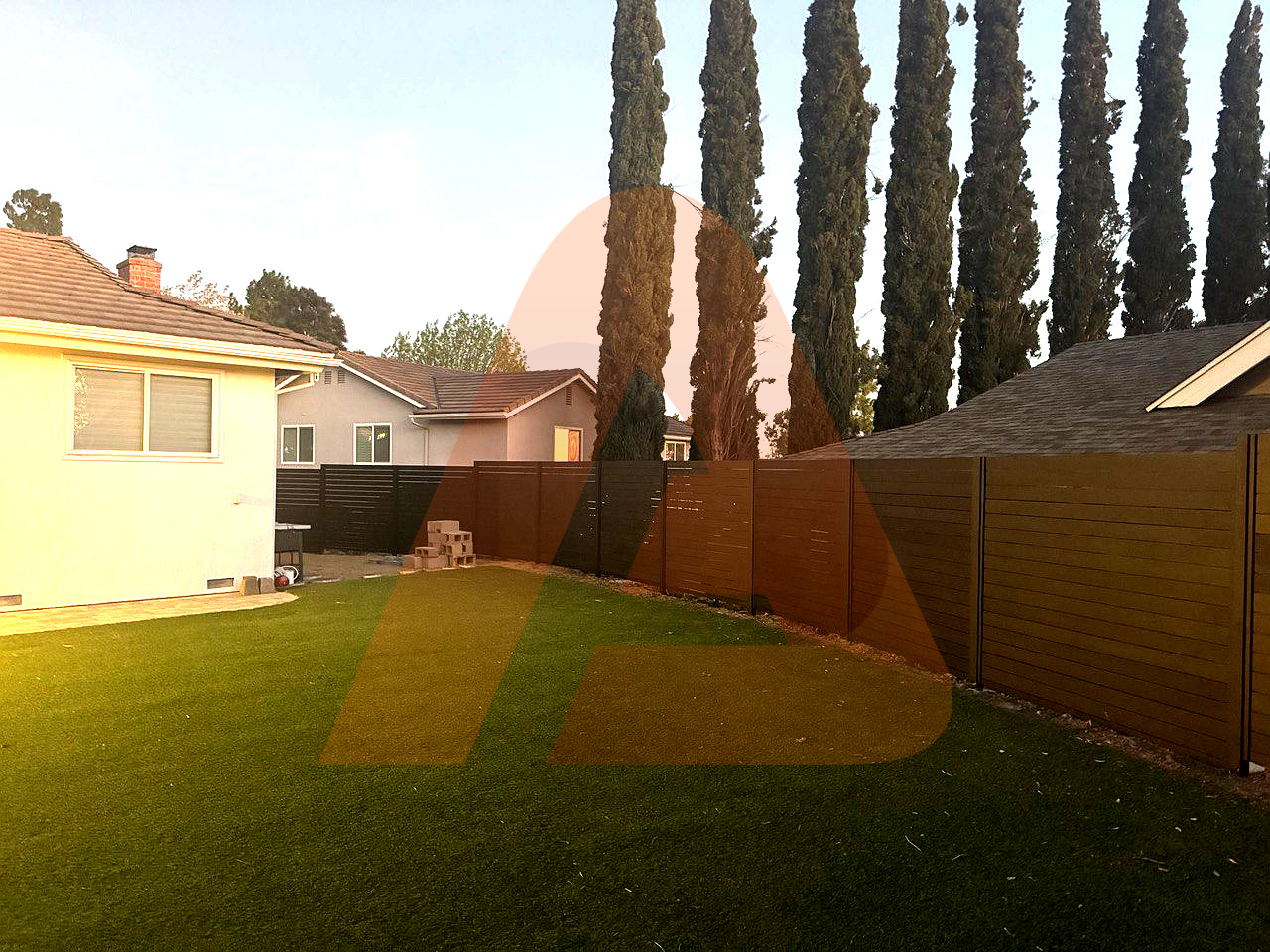

Design Language That Looks Expensive Three Summers From Now (Not Just on Install Day)

Curb appeal is earned in proportion and chemistry, not ornament. In San Jose, aluminum-sliding-gates look premium for years when the face reads like architecture—slat rhythm aligned to garage panels or window mullions, picture-frame borders scaled to the façade, vented density where wind funnels—and the finish is chosen for Valley life: matte/low-satin AAMA 2604/2605 powder that hides dust and hard-water spotting instead of glossy black that fingerprints by noon. On Willow Glen and Rose Garden streets, afternoon sun punishes shiny surfaces and cameras; soft charcoal, bronze, and warm gray stay cooler and don’t blow out video intercoms. In Almaden and Santa Teresa, corridor gusts expose flimsy frames—so you use boxed, welded sections with hidden diagonals and guides that control sway without binding at 3 p.m. heat. Evergreen and Silver Creek bring irrigation and clay: keep the face off grade, isolate stainless fasteners from coated aluminum to kill tea-stain streaks, and route sprinklers so their throw ends at a hardscape strip, not at your gate. If you insist on warmth, add wood or composite inlays inside the aluminum picture frame—but back-vent and drip-path them so you’re not trapping steam, and re-check operator torque because inlays add mass. This is the difference between modern aluminum gates that disappear into the elevation and catalog pieces that turn into a maintenance hobby by July.

San Jose Palettes, Glare, and Night Lighting (Make It Quiet, Not a Runway)

Color is performance. West and south exposures in Willow Glen, Rose Garden, and Almaden need low-sheen powders that don’t act like mirrors; pick tones that echo door/fixture metals so the pedestal and guide posts vanish. Light the leaf like a front door, not a parking lot: warm 2700–3000K grazers at low height, tight beams on the latch zone, zero uplight into lenses. Keep fixtures clear of irrigation (overspray is silent death), land low-voltage in separate conduit from power so intercom audio stays clean, and mount the enclosure in shade so morning condensation doesn’t cook boards. When sliding gate installation respects glare, color temperature, and cable hygiene, the entry reads calm from the street and usable at 10 p.m.—no hotspots, no camera bloom, no “facility” vibe.

Hybrids That Don’t Look Patched (Where Wood Belongs—and Where It Doesn’t)

You can have warmth without buying headaches. Run aluminum (AAMA 2604/2605 + stainless hardware) on the wet stretches—Rose Garden lawns, Willow Glen side yards with daily rotors—and reserve wood/composite inlays for protected spans under eaves or in dry Almaden courts. Keep one rhythm (slat spacing, reveals) and one palette so the mix reads intentional; spec cap-and-trim on redwood/cedar, hold boards off grade, oil both faces at install, and use compression latches so a 30°F day/night swing doesn’t open daylight. For alleys in Japantown/Naglee Park, stick with full aluminum faces or perforated/louver panels inside welded frames so grit and DG don’t turn a ground track into a grinder; if you do inlay, back-vent and accept the mass in your torque calc. Hybrids done this way keep the “San Jose modern” look you want and still cycle like aluminum-sliding-gates should—quiet, clean, and boring in the best possible way.

Site Prep, Runback, and Drainage—Build the Pocket Once, Not Twice

Aluminum-sliding-gates live or die on ground work, not powder color. San Jose driveways stack three headaches—short aprons, quirky slope, and relentless irrigation—so the pocket and threshold have to be engineered on paper and built like you mean it. Start by shooting the apron from curb to gate line and across the threshold; if the slope fights a swing, you’ve already justified sliding gate installation to the inspector. For tracked systems in Willow Glen and Rose Garden, you cut a true line for the rail, set it on a flat-bearing substrate (no random pavers), and grade a micro-fall toward a linear drain or daylight discharge at the pocket so last night’s rotors don’t flood bearings. Where the runback hugs walls, meters, or planting beds, you draw the clear envelope in inches—leaf thickness, rollers, guide hardware, and a heat-expansion buffer—so the panel never kisses masonry at 3 p.m. In Japantown/Naglee Park alleys or Evergreen side yards where DG and leaf litter are chronic, you stop pretending housekeeping will be perfect and call a cantilever: oversize posts at proper spacing, sealed carriage bearings, stiffer boxed frames on your modern aluminum gates, and guide geometry that controls sway without binding when metal grows in heat. Every penetration gets sealed glands with drip loops; every conductor is sized with voltage-drop math from panel → pedestal → operator; every irrigation head gets re-aimed or a 12–18″ hardscape strip so hard water doesn’t haze the face by June. Put the boring lines into the submittal—runback length, drain detail, pocket clearances, enclosure location (shade), AAMA 2604/2605 powder code, stainless hardware with isolation—and the slider stops being a project and becomes infrastructure that cycles quiet through three San Jose summers.

Short Aprons, Slope, and Pocket Geometry (Willow Glen, Rose Garden, Cambrian)

Short aprons pick your mechanism for you. If a bumper nosed to the line would intersect a swing arc or a sloped sidewalk would force toe-in/toe-out limits, aluminum-sliding-gates are the only adult answer. Tracked works here if you mill the threshold honest: broom-finish concrete or tightly laid pavers with a straight, crowned lane, a rail seat that doesn’t rock, and a line to daylight at the pocket so irrigation and storm wash leave as fast as they arrive. Draw the pocket like cabinetry: leaf thickness, roller stack, guide posts, and a clearance margin for thermal growth; if you can’t keep 1–1.5″ of honest air on the hot side, adjust fence rhythm or jump to cantilever. Pedestals mount at 48–54″ reach so drivers don’t block sidewalk egress, devices aim out of west glare, and the controller lives on the shade side of the wall—San Jose sun cooks boards when you get cute. This is sliding gate installation tuned for valley geometry: scale, clearance, drainage, and shade, not vibes.

Debris, DG, and Alley Reality (Japantown, Naglee Park, Evergreen, Alum Rock)

Tracks and grit hate each other. If your runback shares real estate with DG paths, jacaranda litter, or alley sweepings, tracked sliders become grinders and callbacks. Cantilever the leaf: specify larger posts and real footings (depth/diameter keyed to height and wind), a carriage spacing that carries the span without belly, and side guides that keep the panel from wagging without pinching when aluminum expands at 3 p.m. heat. Pocket faces get matte/low-satin powder (AAMA 2604/2605) so cameras don’t flare; stainless hardware is isolated from coated aluminum so you don’t grow tea-stain freckles; and any nearby irrigation gets hardscape buffers so you aren’t rinsing bearings every weekend. Run a spare conduit for future access even if you’re manual now, keep low-voltage separate from power, and tape a one-pager inside the enclosure space with conductor gauge, trench length, and leaf weight so the operator spec isn’t guessed later. Do that, and your modern aluminum gates roll like a machine on day one—and keep doing it after the first heat wave, first leaf drop, and first winter rain.

Approvals, HOA, and First-Pass Inspections (Get Stamped Once in San Jose)

Paperwork moves projects here, not promises. For aluminum-sliding-gates, your submittal needs to read like a build plan, not a mood board: a to-scale site plan with the gate line clearly inside setbacks; driveway apron depth measured curb → gate line; slope across the threshold in inches; and either a tracked runback pocket drawn to scale with drainage to daylight or a cantilever layout showing post section, carriage spacing, and guide geometry. Corner parcels (Berryessa/North Valley) must show visibility triangles with density tapered near the cone; alley work (Japantown/Naglee Park) must prove the leaf never enters public right-of-way. Materials are named like adults—AAMA 2604/2605 powder codes for the modern aluminum gates face over documented pretreat, stainless hardware called by grade with isolation where stainless meets coated aluminum, and enclosure rating/location (NEMA 4/4X, shade) printed in ink. If power is present (now or later), include conductor gauge with voltage-drop math panel → pedestal → operator and a UL 325/ASTM F2200 safety map even if you’re commissioning manual on day one (photo-eye heights, monitored edges at the pocket mouth and leading edge, loop locations so vehicles clear the sidewalk before motion). Elevations show finished heights at both high/low grade; side sections call out bottom clearance so the leaf doesn’t plow pavers. Do this and your sliding gate installation passes once—no “come back with a real drawing” loop that eats three weeks.

HOA / ARC Submittals That Don’t Neuter the Design (Almaden, Silver Creek, Berryessa)

ARC boards here hate glare and clutter, not gates. Give them a calm palette (matte/low-satin charcoal/bronze/warm gray), a slat rhythm that aligns to garage panels or window mullions, and a rendering that shows the slider parallel to the street so egress sightlines stay open. Call out the pocket screening, pedestal location at 48–54″ reach, and finish continuity between devices and gate (no mixed sheens). In irrigation-heavy tracts, specify aluminum with AAMA 2604/2605 and stainless hardware (plus isolation) on any span that gets daily spray; if you’re adding wood/composite inlays for warmth, show back-vent/drip details and note the updated leaf weight so operator sizing isn’t a mystery. Bring one page of nearby precedent approvals and you’ll shave a week—the ARC moves faster when they’re blessing their own history.

Inspector Walk-Through: What They Actually Check (So You Pass the First Time)

Field day is boring if your packet matched the dirt. Pre-pour, the city wants open holes with depth/diameter tagged for posts and guide posts (bigger at cantilever supports), crowned concrete above grade, and—on tracked systems—proof the rail seat is straight and the pocket drains to daylight. They’ll stand at the apron and confirm a swing arc won’t ever exist (that’s why you chose aluminum-sliding-gates), then check visibility triangles and that your upper third is open where required. If automation is in scope, they’ll look for two photo-eye zones (bumper ~18–24″, stroller/walk path ~36–40″) aimed out of headlight/sunset glare, monitored edges on the leaf and pocket mouth, and loops that let vehicles clear the sidewalk before motion; obstruction forces get tuned with a human present, not factory defaults. Enclosures live in shade with sealed glands and drip loops; low-voltage is routed separate from power; powder chemistry (AAMA code) and hardware metals (stainless grade) are printed on the submittal. If you can point to each of those items on paper and in the ground, inspection becomes a handshake and your sliding gate installation goes straight to commissioning.

Approvals, Property Lines, and First-Pass Inspections (Paper That Saves Weeks in San Jose)

Permits around backyard-fence-installation in San Jose move at the speed of clean drawings and zero guesswork, so front-load the boring details and you’ll build once: a to-scale site plan with the fence/gate line clearly inside setbacks, corner visibility triangles dimensioned on any street frontage, and a simple slope profile in inches per run with RACK (not “trim to suit”) printed where panels will follow grade; elevations at both high and low grade with finished heights called out so no one argues in the field; a footing schedule that ties post diameter/depth to height and exposure (Evergreen/Silver Creek clay ≠ Willow Glen loam, Santa Teresa corridor winds ≠ calm Rose Garden alleys); and explicit gate diagrams—swing arcs or slider runback drawn to scale so you never invade right-of-way or nick garage aprons. Materials must be named like adults (heart redwood/cedar + cap-and-trim + breathable oil; aluminum with AAMA 2604/2605 powder; steel as duplex—galvanize + powder), hardware metals matched to exposure (stainless/HDG where sprinklers live), and isolation at dissimilar contacts written in. If your scope includes a driveway or alley leaf, add a one-page safety plan even for non-motorized gates (sightlines at egress, latch heights, no swing into sidewalks), and if it’s a pool yard, print latch centerline and swing-away direction in inches. Wrap it with a neighbor memo for shared lines—plan view, height, finish, and dates—because nothing burns time like a fence that’s beautiful and one inch on the wrong side. This is how a “privacy fence installation near me” turns into a first-pass stamp instead of a revision treadmill—and how wood fence installation near me doesn’t become a weekly email thread.

HOA/ARC Submittals That Pass Without Neutering the Design

ARC boards in Almaden, Silver Creek, and parts of Berryessa don’t hate fences; they hate clutter and glare. Give them elevations that align slat/picket rhythm to window mullions so the line reads like architecture, finish chips in matte/low-satin that won’t chalk by June, and a palette that echoes door/fixture hardware instead of fighting it. Call out cap-and-trim on redwood/cedar, real ground clearance so boards don’t wick, and oil systems with UV blockers on a schedule; for metal stretches near daily irrigation, specify aluminum with AAMA 2604/2605 powder and stainless hardware (plus isolation) so they see “low maintenance” not “annual touch-ups.” Corner lots get tapered profiles or open upper thirds near triangles—drawn, not promised—and gates are shown as doors (boxed frames, adjustable hinges, compression latches), not panels on strap hinges. Bring one page of nearby approvals in the same tract and you’ll shave a week; ARCs nod faster when they’re approving precedent, not invention. That’s how backyard-fence-installation clears paperwork in Willow Glen, Almaden, and Evergreen without sanding off everything you liked about the design.

Inspection Day: Pass Once, Pour Once (And Keep Neighbors Calm)

Field passes are predictable if your packet matches the dirt. Pre-pour, post holes are open and photographed with depth/diameter against a tape; footing crowns are shown above grade for drainage; in clay zones you’ve belled or widened where called out and backfilled with clean aggregate; and in windy corridors you’ve tightened on-centers for taller faces so rails don’t belly across 8–10′ bays. Racked panels track slope—no saw-tooth stepping or dog-sized wedge gaps—and any gate arcs/runback are marked on the ground so it’s obvious you’re not entering sidewalks or alleys. If a driveway/alley gate is motorized later, you’ve at least planned for it: conduit in now, swing/slide geometry that already honors sightlines, and a note where photo-eyes would live out of headlight glare. Drop a 48-hour neighbor notice in tight Willow Glen or Japantown blocks, stage panels on stands (not gardens), cone the curb during deliveries, and keep cut stations on plywood so metal dust doesn’t tattoo concrete. Do this, and your “privacy fence installation near me” inspection is a handshake, not a scavenger hunt—and your wood fence installation near me doesn’t hijack the street thread or your week.

Pricing & Bid Reality for Aluminum Sliding Gates in San Jose (Apples-to-Apples, Not Hopes)

Sticker shock is normal; what matters is the spec behind the number. In San Jose, aluminum-sliding-gates price out on geometry (apron depth, slope, pocket length), debris reality (track you’ll actually maintain vs. cantilever that ignores grit), finish chemistry (AAMA 2604 vs. 2605), and a safety/access stack that passes UL 325/ASTM F2200 without “we’ll see onsite.” Cheap quotes usually bury the physics—no leaf weight, no operator torque/duty, no voltage-drop math from panel to pedestal to operator, no pocket clearance, no drainage plan—and then get “discovered” after you sign. Use the ranges below to sanity-check sliding gate installation around Willow Glen, Rose Garden, Almaden, Santa Teresa, Evergreen, Silver Creek, Japantown, and Naglee Park; they assume boxed welded frames, real powder over pretreat, stainless hardware with isolation, and a commissioning/tune that makes the leaf quiet in July heat.

| Scope (San Jose typical) | Installed Range | When It Moves | Main Cost Drivers | Notes |

|---|---|---|---|---|

| Tracked Aluminum Slider 12–16′ (manual) | $4,800 – $9,200 | + if slope, drains, or paving repair | Frame section, rail hardware, pocket length, drainage | Great on clean aprons; needs housekeeping at track & pocket |

| Cantilever Aluminum Slider 12–16′ (manual) | $7,800 – $13,800 | + for long spans or tight posts | Post size/spacing, carriage set, frame stiffness | Best for DG, leaf litter, alleys; no ground track to clog |

| Automation Package (DC operator + battery) | $2,900 – $6,900 | + with heavier faces/inlays | Leaf weight, wind load, duty cycle, soft-start/stop | Size torque to actual mass; avoid catalog optimism |

| UL 325 / ASTM F2200 Safety Stack | $900 – $2,400 | + for long pockets/extra edges | Photo-eyes (2 zones), monitored edges, loops | Heights matter: bumper + stroller levels; draw it in ink |

| Access Pedestal + Keypad/Prox/Video | $750 – $2,200 | + with cellular bridge/hardline | Device mix, vandal housing, cabling runs | Mount at 48–54″ reach; avoid west-sun glare |

| Power & Low-Voltage Trenching | $18 – $45 / ft | + through driveways/roots | Surface type, conduit count, routes | Run voltage-drop math; separate LV from power |

| Runback Pocket & Drainage (tracked) | $650 – $2,000 | + for daylight drain or basin | Excavation, linear drain, discharge path | Stops pocket floods and grit buildup |

| Finish Upgrade (AAMA 2605 powder) | $350 – $1,100 | + on complex palettes | Chemistry, pretreat, color | Worth it on harsh sun/wet zones; matte/low satin only |

| Wood/Composite Inlays (per 12–16′ leaf) | $900 – $2,800 | + operator upsizing | Back-venting, mass, fastening | Add warmth; recheck torque and balance |

| Permits / HOA / Basic Engineering | $600 – $1,900 | + in strict ARCs | Submittal depth, precedent sheets | First-pass packets save weeks of churn |

What a Real San Jose Bid Must Spell Out (So You’re Comparing Systems)

If the proposal doesn’t read like a build plan, it’s a change-order machine. You want driveway physics in writing—apron depth, slope across threshold, runback length/clearances, pocket geometry for tracked or post spacing/carriage layout for cantilever. You want leaf weight and frame section so the operator can be sized to mass plus wind; you want AAMA 2604/2605 powder codes over documented pretreat, stainless hardware named by grade with isolation where stainless meets coated aluminum, and enclosure rating/location (NEMA 4/4X in irrigated zones, shade always). The sliding gate installation packet should show conductor gauge with voltage-drop math for the real trench length, low-voltage paths separated from power, photo-eye heights aimed out of headlight/sunset glare, monitored edges on the leading edge and pocket mouth, loop locations that let vehicles clear the sidewalk before motion, and a drainage detail to daylight at the pocket if you’re tracked. For cantilever, the drawing shows post sections, footing sizes, carriage spacing, and guide geometry that controls sway without binding at 3 p.m. heat. Add a commissioning line item—soft-start/stop profiles recorded, obstruction forces tuned with a human present, limits printed and taped inside the box—and the spec stops being marketing and starts being a machine.

Red Flags That Predict Pain (Walk Away, No Regrets)

“Painted black” with no AAMA code; no leaf weight stated; operator picked by door width, not mass and wind; no runback or pocket clearance on the drawing; ground track proposed for DG/leaf-litter alleys in Japantown or Naglee Park; swing arcs on short Willow Glen aprons that will invade sidewalk; no voltage-drop math for a 100-ft trench; photo-eyes at random heights aimed straight into west sun; zero mention of monitored edges at the pocket mouth; stainless fasteners with no isolation to coated aluminum (hello tea-stain); glossy finishes that will fingerprint and chalk by June; and “we’ll figure drainage onsite.” If a modern aluminum gates bid dodges those lines, the number is fantasy. Hire the crew that writes the boring stuff in ink—their aluminum-sliding-gates roll quiet on day one and still do after three summers.

Design Your Ideal Fence & Gates Today!

Bring your vision to life with premium aluminum fencing, custom gates, and modern cladding solutions crafted to elevate any property.

Schedule A ConsultationCommissioning, Handover, and the 90-Day Tune—Make the Slider Boring (Perfect)

The difference between aluminum-sliding-gates that vanish into daily life and a gadget you babysit is the last 5%—commissioning done like adults and a clean handover. In San Jose that means the crew sights the rail line dead-straight under a string, confirms pocket clearances in hot afternoon temps so thermal growth doesn’t make the leaf kiss masonry at 3 p.m., and dials operator profiles to your driveway physics—not factory defaults. On tracked sliding gate installation in Willow Glen/Rose Garden, they verify the rail sits on a plane (no rocking pavers), drains to daylight at the pocket, and that sweep strips brush fines without turning into a plow; on cantilevers in Japantown/Naglee Park they confirm carriage spacing, side-guide alignment, and that the floating leaf won’t wag when the wind funnels down the alley. Operators are sized to actual leaf weight plus wind load, soft-start/soft-stop is tuned so rack/chain stay quiet, and obstruction forces are set with a human there—not a guess. Photo-eyes sit at bumper and stroller heights, aimed out of headlight and sunset glare; monitored edges live on the leading edge and pocket mouth; loops fire so a car clears the sidewalk before motion. The enclosure sits in shade with sealed glands and drip loops, low-voltage is routed separate from power so intercom audio stays clean, and every conductor gauge is documented with voltage-drop math from panel → pedestal → operator. Finally, the face chemistry gets logged—AAMA 2604/2605 powder code over documented pretreat, stainless hardware grade with isolation where stainless meets coated aluminum—so three summers from now you’re not guessing why a fastener freckled. That’s commissioning for modern aluminum gates in San Jose: not glamorous, totally decisive.

What the Handover Packet Should Contain (So You Never Guess Later)

Your packet isn’t a brochure; it’s a map you—or the next tech—can win with. One page lists driveway geometry (apron depth, threshold slope), mechanism choice (tracked vs. cantilever) with a little sketch of the pocket/runback and clearances in inches, and the final leaf weight for future operator swaps. Another page prints operator model/firmware, soft-start/stop times, obstruction force settings, photo-eye heights and aim notes, monitored edge locations, loop sensitivity, and battery install date; limits are written and a copy is taped inside the NEMA 4/4X box. Finish sheet shows AAMA powder code and pretreat, hardware metals by zone (stainless where irrigation lives, HDG where it doesn’t), and isolation pad locations so no one deletes them during a repair. Civil notes include drain detail to daylight (tracked) or carriage/guide geometry (cantilever), plus a diagram of conduits with distances and wire gauges (panel → pedestal → operator; low-voltage separate). Maintenance card is boring and specific: quarterly hose-down of track/pocket in Willow Glen, quick wipe of lenses, brush fines from the sweep; after first heat wave in Almaden/Santa Teresa, re-check guide pressure and force settings; after fall leaf drop in Naglee Park/Japantown, pocket clean-out; after first winter rain in Evergreen/Silver Creek, confirm crowned concrete still sheds and pocket doesn’t pond. If you added wood/composite inlays, a line notes back-venting and the light oil schedule for the inlay faces; if you plan future access, the card shows spare conduit routes. With that handover, sliding gate installation stops being a project and becomes infrastructure: it rolls, it stops, it stays quiet—exactly what you paid for when you chose aluminum-sliding-gates for a San Jose driveway.

Retrofits & Replacements—Turn Tricky Driveways Into Quiet Sliders (San Jose Reality)

Most San Jose installs aren’t blank slates; they’re sagging wood swing gates scraping sloped sidewalks in Willow Glen, rusted tube frames in Rose Garden that tea-stain stucco, or alley pivots in Japantown that block right-of-way. Converting those problems to aluminum-sliding-gates is a geometry + housekeeping project, not just a new leaf: you measure apron depth curb→gate line, shoot threshold slope in inches, and decide tracked vs. cantilever by debris reality (DG paths in Evergreen, leaf litter under jacarandas, alley grit in Naglee Park). If a tracked rail will live clean with a drain to daylight at the pocket, keep it simple; if the surface is chaos, float the mass with a cantilever and oversize posts to carry the span. Retain posts only if they meet today’s section/depth for wind and height; otherwise, reset the line so rails won’t belly and the operator doesn’t mask structural flex. Faces shift to AAMA 2604/2605 powder in matte/low satin (charcoal/bronze/warm gray) over real pretreat, stainless hardware is isolated where it meets coated aluminum so you don’t grow tea-stain freckles, and irrigation gets a 12–18″ hardscape standoff so hard water doesn’t haze the plane by June. The retrofit packet spells pocket/runback in inches, lists leaf weight so torque isn’t guessed, and prints the UL 325/ASTM F2200 safety map even if you’re manual on day one—because future you will automate. Done right, a Willow Glen swing that never cleared the sidewalk becomes sliding gate installation that cycles quiet, stays out of right-of-way, and passes once.

What to Salvage vs. What to Replace (Decide With a Tape and a Wrench, Not Hope)

Keep posts only if they’re plumb under string, don’t pump water, and actually size to span and wind; “pipe in concrete” from 1998 won’t carry a 14–16′ slider without belly. Reuse conduits if they meet voltage-drop math panel→pedestal→operator and separate low-voltage from power; otherwise trench once now and stop paying twice. If you’re attached to wood, inlay warm boards inside welded modern aluminum gates frames—but back-vent and drip-path the inlays and recheck operator torque because mass went up. Salvage an old track only when it sits on a single plane, can be crowned toward a drain, and the pocket clears the leaf at 3 p.m. heat; if DG, roots, or pavers move, jump to cantilever and delete the grinder. Every salvage decision ends up in the drawing: post section/depth, carriage spacing, guide geometry, pocket clearance, finish chemistry, hardware metals, and—always—leaf weight. If a bid can’t print those, it’s guessing with your driveway.

“Automate Later” Without Future Demo (Prewire, Pocket, and Device Geometry Now)

San Jose owners add motors six months after they fall in love with the slider; plan it today so you don’t trench gardens tomorrow. Run spare conduit (separate LV from power), land it in shade at a NEMA 4/4X enclosure pad, and sketch device locations like adults: photo-eyes at bumper height (18–24″) and stroller height (36–40″) aimed away from headlight/sunset glare, monitored edge on the leading edge and at the pocket mouth, and loop sawcuts where a car clears the sidewalk before motion. In HOA tracts (Almaden/Silver Creek), pick a pedestal finish that matches the gate powder (matte/low satin) so the stack disappears; in alleys (Japantown/Naglee Park), keep devices inside the line with vandal-resistant housings and blinded screwheads. Note leaf weight on the handover card, print soft-start/stop targets, and leave a drain sketch for tracked pockets—or carriage/guide geometry for cantilever—so the next tech doesn’t guess. That’s how aluminum-sliding-gates stay future-proof: the wiring’s there, the safety map’s solvable, and the pocket was built once.

Retrofits & Replacements—Turn Tricky Driveways Into Quiet Sliders (San Jose Reality)

Most San Jose installs aren’t blank slates; they’re sagging wood swing gates scraping sloped sidewalks in Willow Glen, rusted tube frames in Rose Garden that tea-stain stucco, or alley pivots in Japantown that block right-of-way. Converting those problems to aluminum-sliding-gates is a geometry + housekeeping project, not just a new leaf: you measure apron depth curb→gate line, shoot threshold slope in inches, and decide tracked vs. cantilever by debris reality (DG paths in Evergreen, leaf litter under jacarandas, alley grit in Naglee Park). If a tracked rail will live clean with a drain to daylight at the pocket, keep it simple; if the surface is chaos, float the mass with a cantilever and oversize posts to carry the span. Retain posts only if they meet today’s section/depth for wind and height; otherwise, reset the line so rails won’t belly and the operator doesn’t mask structural flex. Faces shift to AAMA 2604/2605 powder in matte/low satin (charcoal/bronze/warm gray) over real pretreat, stainless hardware is isolated where it meets coated aluminum so you don’t grow tea-stain freckles, and irrigation gets a 12–18″ hardscape standoff so hard water doesn’t haze the plane by June. The retrofit packet spells pocket/runback in inches, lists leaf weight so torque isn’t guessed, and prints the UL 325/ASTM F2200 safety map even if you’re manual on day one—because future you will automate. Done right, a Willow Glen swing that never cleared the sidewalk becomes sliding gate installation that cycles quiet, stays out of right-of-way, and passes once.

What to Salvage vs. What to Replace (Decide With a Tape and a Wrench, Not Hope)

Keep posts only if they’re plumb under string, don’t pump water, and actually size to span and wind; “pipe in concrete” from 1998 won’t carry a 14–16′ slider without belly. Reuse conduits if they meet voltage-drop math panel→pedestal→operator and separate low-voltage from power; otherwise trench once now and stop paying twice. If you’re attached to wood, inlay warm boards inside welded modern aluminum gates frames—but back-vent and drip-path the inlays and recheck operator torque because mass went up. Salvage an old track only when it sits on a single plane, can be crowned toward a drain, and the pocket clears the leaf at 3 p.m. heat; if DG, roots, or pavers move, jump to cantilever and delete the grinder. Every salvage decision ends up in the drawing: post section/depth, carriage spacing, guide geometry, pocket clearance, finish chemistry, hardware metals, and—always—leaf weight. If a bid can’t print those, it’s guessing with your driveway.

“Automate Later” Without Future Demo (Prewire, Pocket, and Device Geometry Now)

San Jose owners add motors six months after they fall in love with the slider; plan it today so you don’t trench gardens tomorrow. Run spare conduit (separate LV from power), land it in shade at a NEMA 4/4X enclosure pad, and sketch device locations like adults: photo-eyes at bumper height (18–24″) and stroller height (36–40″) aimed away from headlight/sunset glare, monitored edge on the leading edge and at the pocket mouth, and loop sawcuts where a car clears the sidewalk before motion. In HOA tracts (Almaden/Silver Creek), pick a pedestal finish that matches the gate powder (matte/low satin) so the stack disappears; in alleys (Japantown/Naglee Park), keep devices inside the line with vandal-resistant housings and blinded screwheads. Note leaf weight on the handover card, print soft-start/stop targets, and leave a drain sketch for tracked pockets—or carriage/guide geometry for cantilever—so the next tech doesn’t guess. That’s how aluminum-sliding-gates stay future-proof: the wiring’s there, the safety map’s solvable, and the pocket was built once.

Maintenance, Warranty, and Owner One-Pager (Keep It Quiet for Three Summers)

San Jose eats lazy specs with UV, hard water, clay movement, and corridor wind; aluminum-sliding-gates that still feel “new” in year three are the ones you maintain like a machine, not a sculpture. The routine is boring and specific: pocket/track kept clean (or zeroed with cantilever if debris is chronic), drain to daylight proven after the first hose test, faces rinsed where sprinklers haze, and a shaded NEMA 4/4X enclosure with sealed glands and drip loops so morning condensation in Willow Glen doesn’t cook boards. Commissioning notes get saved and followed—soft-start/stop times, obstruction forces set with a person standing there, loop sensitivities printed—because sliding gate installation fails when settings drift and nobody remembers what “good” was. Finish chemistry matters more than color: AAMA 2604/2605 powder on the modern aluminum gates face, stainless hardware with isolation where stainless meets coated aluminum, and sealed penetrations so water can’t sit; inlays (wood/composite) are back-vented and drip-pathed so steam doesn’t balloon panels in July. Do the micro stuff on a schedule and your slider stays invisible in the best way—one touch, no rattle, no chores.

Seasonal Care That Takes 10 Minutes (But Saves Service Calls)

Quarterly in Willow Glen/Rose Garden: hose dust and hard-water film off the face, brush fines from the sweep (tracked) or blow out carriage pockets (cantilever), wipe photo-eye lenses, and peek at gasketed glands on the enclosure. After the first heat wave in Almaden/Santa Teresa: cycle the leaf a dozen times, listen for “chatter,” back off guide pressure a hair if thermal growth is pinching, confirm soft-start/stop is smooth, and re-verify obstruction forces with a person there—not factory defaults. After fall leaf drop in Japantown/Naglee Park: clear the pocket, confirm monitored edges at the pocket mouth aren’t taped over by a “temporary” fix, and check that loop sawcuts haven’t filled with grit so cars still clear the sidewalk before motion. Evergreen/Silver Creek clay after first winter rain: confirm crowned concrete still sheds, pocket doesn’t pond, and posts at guides haven’t heaved; tweak guides if needed so the leaf can’t kiss masonry at 3 p.m. Keep irrigation throws ending at a 12–18″ hardscape strip; rotors fogging the face are silent finish killers. This ten-minute cadence is the entire difference between “new gate” and “new project.”

Warranty Terms That Mean Something (And the Weasel Words to Reject)

Useful coverage ties to the spec in ink: face finish warrants by AAMA code (2604/2605) over documented pretreat, not “painted black”; hardware covers stainless grade and isolation at stainless-to-aluminum contacts (no tea-stain loopholes); structure names boxed frame section and guides/bearings by model so “wear item” exclusions don’t swallow the whole leaf; electronics list operator model/firmware, surge protection, battery date, and that UL 325/ASTM F2200 safety devices are monitored—not “present.” Service includes a 30–90 day tune (force check, limit verify, guide pressure set in afternoon heat). Red flags: “lifetime workmanship” with no reference to track/pocket drainage, “cosmetic finish” exclusions that ignore hard-water haze after normal rinsing, operator warranties voided by “non-approved access gear” (you want UL-listed interoperability), and any packet with no printed leaf weight (torque sizing is guesswork without it). Make the sliding gate installation contract read like the machine you bought; if a bidder can’t write those lines in plain English, walk—your aluminum-sliding-gates deserve grown-up paperwork.

Design Your Ideal Fence & Gates Today!

Bring your vision to life with premium aluminum fencing, custom gates, and modern cladding solutions crafted to elevate any property.

Schedule A ConsultationReal San Jose Case Studies—Turning Problem Driveways Into Quiet Sliders

The fastest way to see why aluminum-sliding-gates dominate San Jose is to look at jobs that looked “simple” until the street, slope, and sprinklers spoke. Willow Glen and Rose Garden give you short aprons and daily irrigation that haze lazy powder and corrode mixed-metal fasteners; Japantown and Naglee Park add alleys with grit, meters, and trash-day chaos where a swing arc instantly invades right-of-way; Almaden and Santa Teresa stack corridor winds on long, sun-blasted spans that expose flimsy frames; Evergreen and Silver Creek ride expansive clay that tilts lazy footings and swells under pockets you forgot to drain. The fixes that stuck all started with driveway physics on paper—apron depth from curb to gate line, threshold slope in inches, runback/pocket geometry drawn to scale—and then picked the mechanism and finish to survive the block: tracked when housekeeping and drainage were honest, cantilever when DG/leaf litter or alley grit would grind a ground rail; AAMA 2604/2605 matte/low-satin powders over documented pretreat on the modern aluminum gates face; stainless hardware with isolation pads at stainless-to-aluminum contacts; shaded NEMA 4/4X enclosures with sealed glands and drip loops; and UL 325/ASTM F2200 safety mapped even when the owner insisted on “manual for now.” Every winning sliding gate installation also logged leaf weight to size torque (no catalog optimism), separated low-voltage from power to keep intercom audio clean, and showed drainage to daylight at the pocket so hard water and winter rain didn’t pond. That’s the pattern: measure first, specify like adults, and the leaf becomes quiet infrastructure that passes once and stays boring for three summers straight.

Willow Glen / Rose Garden—Short Apron, Sprinklers, and a Tracked Slider That Actually Lasts

Classic failure: a wood double-swing scraping a sloped sidewalk and fogged daily by sprinklers, replaced twice with “painted black” tube frames that tea-stained the stucco by July. The adult rebuild started with geometry: curb-to-gate apron depth too short to swing without entering right-of-way, threshold pitching 1–1.5″ across 12′, and a tight runback against a garage wall. Solution: tracked aluminum-sliding-gates with a boxed, welded frame (hidden diagonals), sealed carriages on a rail set into a true, crowned lane, and a linear drain to daylight at the pocket. We drew the pocket like cabinetry—leaf thickness, roller stack, guide post offset, 1–1.5″ thermal-growth clearance—and moved rotors behind a 12–18″ hardscape strip so hard water mist stopped hazing the face. Finish: AAMA 2605 matte charcoal over documented pretreat; hardware: stainless with isolation pads wherever stainless met coated aluminum; enclosure: shaded NEMA 4/4X with drip loops; conductors: gauge listed with voltage-drop math panel → pedestal → operator; safety: photo-eyes at ~20″ (bumper) and ~38″ (stroller) aimed out of glare, monitored edge at the pocket mouth, loops cut so a car clears the sidewalk before motion. Result: one-hand cycles, no rattle, no sidewalk violations, no summer freckles—and a packet any inspector could bless in one walk.

Japantown / Naglee Park Alley—Grit, Meters, and a Cantilever That Ignores Debris

Alley pivots here die fast: strap-hinge swings that block right-of-way, ground tracks jammed by DG and leaf litter, and meter clusters the leaf kisses every hot afternoon. The fix was a cantilever sliding gate installation that carried the mass clear of grit: oversized posts at proper spacing, sealed carriage bearings, a stiffer boxed aluminum frame that didn’t belly across 14–16′, and side guides set to control sway without binding at 3 p.m. heat. We kept every device inside the line—vandal-resistant pedestal at 48–54″ reach, camera aimed out of headlight/sunset glare—and ran a cellular bridge (stucco kills Wi-Fi) behind a UL-listed controller that still works when the cloud doesn’t. Finish stayed low-satin (AAMA 2604/2605) in warm gray so cameras didn’t blow out; stainless fasteners were isolated at all stainless-to-aluminum contacts; pocket clearances were drawn in inches around meters and stucco; low-voltage ran in its own conduit away from power; and the safety map called out monitored edges on the leading edge and pocket mouth even though the owner planned to automate “later.” Leaf weight lived on the handover card, obstruction forces were tuned with a person standing there, and the maintenance line was honest: blow carriage pockets after leaf drop, quick quarterly wipe of lenses, and a once-a-season glance at glands. Net effect: a slider that never enters the alley, ignores debris, reads calm at night, and—most important—stays out of neighborhood threads because it just works.

Diagnostics & Tuning—Fix Annoyances Before They Become Service Calls

The reason aluminum-sliding-gates feel “new” in year three is because someone tuned the machine when San Jose conditions changed—first heat wave in Almaden, first leaf drop in Japantown, first winter rain in Evergreen clay—not six months later when a neighbor complains. Start with the simple killers: grit in a tracked pocket because DG migrated or rotors misted the lane; thermal growth that tightens side guides until the leaf chirps at 3 p.m.; photo-eyes aimed straight into west sun along Rose Garden streets; a controller shoved into full sun so board temps drift and obstruction logic gets jumpy; a ground that subtly heaved under guide posts in Silver Creek, making the leaf kiss masonry in the afternoon. A grown-up sliding gate installation checklist reads like a pilot’s: wipe lenses; confirm photo-eye heights (bumper ~20″, stroller ~38″) and aim away from glare; brush/flush the pocket or, if you live in a debris corridor, accept that you needed a cantilever; run the leaf repeatedly when the apron is hottest and back off guide pressure a hair if travel chatters; re-do your voltage-drop math if someone extended the run to the pedestal and the operator now “sort of” starts on hot days; and verify that the pocket still drains to daylight after landscapers re-graded a bed. Most “mystery” problems in modern aluminum gates are consequence, not defect: a finish that chalks was glossy instead of AAMA 2604/2605 matte; tea-stain freckles around screws came from stainless touching coated aluminum with no isolation; false reversals came from eyes in headlight/sunset glare; noise came from guides set cold, not hot; and controller weirdness came from a box mounted in direct sun. Tune against the block you live on—UV, hard water, clay, wind—and the leaf goes back to being boring, which is the correct outcome.

False Reversals, Phantom Opens, and “It Only Happens at Night” (Sensor/Power Reality)

When aluminum-sliding-gates reverse “for no reason,” it’s never random. In Willow Glen and Rose Garden, sunset blasts photo-eyes if you mounted them at the wrong angles; fix the aim and add small hoods, don’t crank obstruction forces to unsafe levels. In Japantown alleys, car headlights at the turn-in can white-out lenses or confuse poorly aimed devices; rotate the eyes, move them a few inches off the beam line, and make sure you’ve got two zones (bumper + stroller height) so pets and carts don’t become edge cases. Phantom opens? Not ghosts—loops too sensitive, wires sharing conduit with power, or an access device bouncing on marginal Wi-Fi. Separate low-voltage from power, retune loop sensitivity so a car clears the sidewalk before motion, and, in stucco-heavy blocks where signal is trash, stop pretending 2.4 GHz will save you—hardline or a cellular bridge behind a UL-listed controller is the adult fix. If you added wood/composite inlays to your modern aluminum gates after the fact and the operator now “struggles,” weigh the leaf and re-size torque; catalog optimism isn’t physics. The pattern holds across San Jose: identify the environmental trigger (glare, heat, grit, RF), adjust placement/aim/pressure for that trigger, and stop fighting the symptom with unsafe force settings.

Chatter, Drag, and Midday Stalling (Heat, Guides, and Housekeeping)

Noisy travel at 3 p.m. is a settings problem you can hear. Aluminum grows in heat; guides set “perfect” at 8 a.m. will pinch after lunch on Almaden and Santa Teresa courts. Back the guides off until the leaf stays in plane without rubbing, then cycle through the hottest hour to confirm. On tracked sliding gate installation, listen at the pocket: a crunchy first foot is grit from DG paths or tree litter—sweep and flush, then prove the drain to daylight isn’t silted shut; if you’re spending Saturdays vacuuming a rail in Evergreen, you specified the wrong mechanism—go cantilever and delete the grinder. Midday stalls on operators that were fine in spring usually come down to voltage drop plus heat soak: measure line-to-line at the operator while the motor starts; if it sags, you undersized conductors for the actual trench length or tied low-voltage in the same pipe and invited noise. Fix the wiring, move the enclosure into shade (NEMA 4/4X, sealed glands, drip loops), and re-tune soft-start/stop so the rack/chain isn’t slamming. Faces that rattle after the first Santa Teresa gust want a mid-rail at dog-push height or a vented profile (narrow horizontals with reveal, perforated/louver infill) so wind bleeds instead of drumming. Do these boring moves and aluminum-sliding-gates go back to being what you bought: quiet, compliant, predictable—no babysitting, no drama.

Retrofits & Replacements—Turn a Tired Line Into Quiet Infrastructure

Most San Jose projects aren’t blank lots; they’re leaning fences with blotchy stain, mismatched repairs, and gates that grind after hot afternoons. A smart backyard-fence-installation retrofit starts with a slope profile (inches per bay), a soil read (Evergreen/Silver Creek clay vs. Willow Glen loam), and a sprinkler audit (Rose Garden overspray is silent death), then decides what to salvage without importing yesterday’s problems. If posts are straight, sound, and set to honest depth/diameter, you can sometimes keep them—but only if they meet today’s span and wind math and sit clear of constant irrigation; otherwise, you’re dressing a crack. Long rear runs in Almaden and Santa Teresa often belly because rails were undersized; fix that with rail sections chosen for 8–10′ bays and panels racked to grade so bottoms hug the land instead of stepping into dog-sized wedge gaps. Where irrigation never stops (Willow Glen, Rose Garden), switch wet stretches to aluminum with AAMA 2604/2605 powder and stainless hardware (isolate stainless-to-aluminum contacts), keep redwood/cedar where it stays dry, and carry one rhythm so the hybrid reads designed, not patched. Gates get rebuilt as doors—boxed frames, hidden diagonals, co-axial adjustable (nylon-lined or greasable) hinges, compression latches—so a 30°F day/night swing doesn’t open daylight and a 70-lb shepherd can’t rattle the latch. This is the retrofit logic that turns “privacy fence installation near me” from a stain refresh into quiet infrastructure that survives three summers.

Reuse Posts or Reset the Line—Decide With a Wrench and a Tape, Not Hope

Sentiment says “save the posts”; physics sometimes agrees. In Willow Glen/Cambrian, pull caps and test with a wrench—if posts twist, pump water, or sit inside mulch that keeps them wet, they’re done. In Evergreen/Silver Creek clay, assume seasonal movement: if your footing wasn’t belled or widened and the concrete isn’t crowned above grade, expect tilt; resetting now is cheaper than shimming forever. On long Almaden backs, rails sized wrong for 10′ bays will telegraph sag through any new face you hang—respec the rail section or live with the belly. If posts are salvageable but irrigation blasts them daily, sleeve or switch those bays to aluminum so you’re not painting hardware every June. Any reuse plan still needs today’s details: panels racked (not stepped) to kill wedge gaps, cap-and-trim on redwood/cedar with true ground clearance, and isolation pads anywhere stainless meets coated metal so you don’t tea-stain around fasteners. If your “wood fence installation near me” bid doesn’t include a pass/fail checklist for each post (depth, plumb, exposure, irrigation), it’s guessing—and you’ll be paying twice.

“We’ll Automate Later”—Prewire and Draw the Safety Now or Pay for Concrete Twice

Rear gates off alleys and long side-yard doors in Naglee Park, Japantown, and Willow Glen get automated after the fact all the time; do the prep during backyard-fence-installation so you don’t trench flower beds next year. Run spare conduit now (separate low-voltage from power), land it in a shaded mounting zone for a future enclosure, and pick gate geometry that will pass sightlines and not invade right-of-way—slider runback drawn to scale or swing arcs that stay inside the parcel. Even if you’re staying manual today, sketch the UL map like adults: where photo-eyes would live out of headlight glare, where monitored edges fit on pinch points, and where loops would cut the drive so cars clear the sidewalk before motion. Choose faces that won’t become sails when you add an operator (narrow horizontals with reveal, alternating boards, perforated/louvered panels inside welded frames), keep hardware stainless/HDG in irrigated zones, and tape a one-pager inside the enclosure space that lists conduit routes and leaf weight for future sizing. That’s how “later” doesn’t become “demo.”

Final Thoughts: Engineer for San Jose’s Driveways—Then Your Aluminum Slider Disappears (In the Best Way)

If you want aluminum-sliding-gates that still feel “new” after three summers in San Jose, stop treating the gate like décor and start treating it like infrastructure. Geometry picks the mechanism first—apron depth, threshold slope, and right-of-way kill swing arcs on most Willow Glen and Rose Garden fronts, while DG paths and alley grit in Japantown/Naglee Park often force cantilever instead of tracked rails—and then the chemistry and wiring keep it quiet: AAMA 2604/2605 matte/low-satin powder over real pretreat on the face, stainless hardware with isolation where stainless meets coated aluminum so you don’t grow tea-stain freckles, a shaded NEMA 4/4X enclosure with sealed glands and drip loops, and conductor gauges chosen with voltage-drop math panel→pedestal→operator so the DC motor isn’t starving on hot afternoons. The drawing for your sliding gate installation prints runback pocket or carriage/guide geometry to scale, maps UL 325/ASTM F2200 safety (photo-eyes at bumper/stroller heights, monitored edges at the pocket mouth and leading edge, loops so vehicles clear sidewalks before motion), and names leaf weight so torque isn’t guessed; commissioning dials soft-start/stop and obstruction forces with a human there, not factory defaults. Do those “boring” things once, and your modern aluminum gates stop being a project and start being the quiet, compliant machine you forget—exactly the goal in San Jose heat, clay, wind, and sprinklers.

Design Your Ideal Fence & Gates Today!

Bring your vision to life with premium aluminum fencing, custom gates, and modern cladding solutions crafted to elevate any property.

Schedule A ConsultationFrequently Asked Questions

Pick by debris and geometry, not preference. Tracked aluminum-sliding-gates win on clean, controllable surfaces—straight broom-finish or tight pavers with a crowned rail lane and a drain to daylight at the pocket—typical of calmer Almaden courts and many Rose Garden aprons; they roll fast and feel invisible when you’ll actually keep the track clear and water moving. Cantilever wins where grit is a lifestyle: DG side yards in Evergreen/Alum Rock, leaf-drop corridors under jacarandas, and Japantown/Naglee Park alleys with meters and trash day chaos. Cantilever deletes the ground rail (and the grinder that comes with it), but asks for stiffer boxed frames, larger posts at proper spacing, and side guides set to control sway without binding at 3 p.m. heat. If a contractor proposes a ground track where DG drifts or a swing arc on a short Willow Glen apron that will invade sidewalk, they’re selling change orders; the adult sliding gate installation shows the pocket or carriage/guide geometry in inches on the drawing so everyone can see the physics before you sign.

Matte/low-satin AAMA 2604/2605 architectural powder over documented pretreat on the modern aluminum gates face, full stop; skip glossy blacks that chalk and fingerprint by June. Pair that with stainless fasteners where irrigation hits and isolation pads wherever stainless meets coated aluminum so you don’t build a galvanic science project that tea-stains the posts by Labor Day. Seal penetrations, route irrigation throws to end at a 12–18″ hardscape strip (not at the face), and mount enclosures in shade with sealed glands and drip loops; San Jose’s hot afternoons + morning condensation will cook boards if you slap a controller in the sun. If you add wood/composite inlays for warmth, back-vent and drip-path those panels so heat/steam doesn’t balloon them, and re-compute leaf weight so the operator isn’t undersized. This chemistry + housekeeping combo is why aluminum stays “set-and-forget” next to turf and planters where wood would live on a maintenance treadmill.

Plan the envelope like cabinetry. For tracked aluminum-sliding-gates, you need a straight, stable lane across the threshold and a pocket that clears the leaf thickness, roller stack, guide posts, and a modest thermal-growth buffer so the panel never kisses masonry at 3 p.m.—plus a drain to daylight so irrigation and storm wash don’t pond. For cantilever, budget extra length for the counterbalance portion of the leaf and set your support posts at proper spacing so the carriages actually carry the mass without belly; then draw side-guide geometry so sway is controlled without binding in heat. In both cases, print the clearances in inches on the submittal (runback length, guide offsets, bottom clearance over pavers) and show where pedestals and meters sit; guessing is how sliders hit walls and inspectors say “come back with a real drawing.” A credible sliding gate installation packet shows those numbers in ink and passes once.

Yes—if you treat the aluminum as structure and the inlay as a controlled accent. Weld a boxed aluminum picture frame, back-vent and drip-path the inlay so heat and water can leave, keep boards off grade, and specify a breathable oil (not a plastic film) if you use real wood. Mechanically, more mass means you must log leaf weight and size operator torque accordingly; electrically, keep low-voltage separate from power so video/audio doesn’t get noisy; cosmetically, keep one rhythm (slat spacing/reveals) and one palette (matte/low-satin charcoal/bronze/warm gray) so the mix reads designed, not patched. In irrigated Rose Garden stretches, run full aluminum faces; tuck the warm inlays under eaves or on drier Almaden spans. Done this way, hybrids keep the San Jose modern look you want while behaving like modern aluminum gates should—quiet and boring in the best way.

Apples-to-apples means writing the physics down: curb→gate apron depth, threshold slope in inches, chosen mechanism (tracked pocket with drainage or cantilever carriage/guide layout) drawn to scale, leaf weight, frame section, and post/footing schedule by height and exposure. The finish sheet names AAMA 2604/2605 powder over pretreat; hardware calls stainless by grade with isolation at stainless-to-aluminum contacts; enclosure shows NEMA 4/4X in shade. The safety map (UL 325/ASTM F2200) places photo-eyes at bumper and stroller heights aimed out of glare, monitored edges on the leading edge and pocket mouth, and loops so cars clear the sidewalk before motion. Power shows conductor gauge with voltage-drop math panel→pedestal→operator, and low-voltage runs in separate conduit. Commissioning is a line item—soft-start/stop tuned, obstruction forces set with a person present, limits printed and taped inside the box—and the handover card lists settings, battery date, and seasonal housekeeping. If a sliding gate installation quote dodges any of that, it’s not cheaper—it’s a change-order machine with your address on it.