Wood Fence Cost Calculators for Scottsdale Homeowners: Plan Your Budget

- By alupost

- Posted on

Table of Contents

Wood Fence Cost Calculators for Scottsdale Homeowners

For Scottsdale homeowners planning a privacy upgrade, starting with a wood fence cost calculator gives a grounded, line‑item view of the budget by converting length, height, post spacing, picket dimensions, board style, gate count, and labor assumptions into a realistic estimate that mirrors how bids are structured in Maricopa County, which reduces surprises when comparing quotes and accelerates alignment on scope before utility locates, HOA approvals, and material lead‑time checks are initiated; this approach also makes it easy to test scenarios like 6‑foot privacy versus 5‑foot semi‑privacy, closer post spacing for wind load, or switching from standard pine to cedar, so the financial impact of each decision is visible before committing to a layout or purchase order.

Why a calculator beats guesswork

A dedicated wood fence calculator breaks the project into quantities—posts, rails, pickets, concrete, fasteners, stains or sealers—and ties those to chosen dimensions and spacing so the estimate reflects real‑world builds instead of generic per‑foot averages, allowing homeowners to see exactly how height changes, gate hardware, or decorative top caps move both material and labor. By modeling waste factors, terrain adjustments, and gate framing, the calculator produces a pre‑bid reference that helps standardize contractor proposals, reduces scope creep, and ensures apples‑to‑apples comparisons when multiple Scottsdale installers submit quotes for the same specifications.

How Scottsdale pricing factors in

Local pricing varies with wood species availability, labor rates, and site conditions, so plugging Scottsdale‑specific assumptions into the calculator—such as deeper post embeds for monsoon wind considerations, concrete volume per post, and premium hardware for heat exposure—yields estimates that better match final invoices, especially on 6‑foot privacy runs with multiple gates. Because neighborhoods often include HOA guidelines on height, visibility, and finish tones, pre‑configuring the calculator to those rules avoids rework, supports faster approvals, and clarifies the budget impact of compliance items like cap‑and‑trim or uniform stain colors.

How to use the calculator

Using a wood fence cost calculator starts with precise field measurements and input choices that reflect Scottsdale realities, which means walking the fence line with a tape or wheel to capture true linear footage including offsets around AC units, pool equipment, or block walls, recording slopes or grade breaks that change post embed depths and rail alignment, and marking planned gate locations so openings are subtracted from picket counts while additional framing and hardware are added; then, entering target height (often 6 feet for privacy), post spacing (6–8 feet on center), picket width and gap (full privacy, board‑on‑board, or shadowbox), species (pine, cedar, or redwood), and the number and type of gates (pedestrian versus driveway) allows the calculator to translate dimensions into posts, rails, pickets, concrete, and hardware, apply waste factors for cutting and defects, and layer labor at Scottsdale rates, producing a realistic subtotal and grand total that better matches what contractors will quote, while also letting homeowners A/B test scenarios like tighter post spacing for wind resilience, upgrading to cedar for longevity, or adding cap‑and‑trim without losing sight of the budget target established for the property.

Optimizing inputs for accuracy

To optimize accuracy, it helps to set calculator defaults that mirror common Scottsdale specs—6‑foot height for privacy runs, 8‑foot maximum spans for rails to limit sag, 6×6 posts in high‑wind exposures or soft soils, and concrete volumes that reflect deeper embeds for monsoon gusts—then refine by yard section, because a flat side yard can tolerate standard spacing while a sloped rear run may need stepped panels, additional posts, and more concrete; similarly, factoring in pre‑stain or sealant, upgraded hinges and self‑closing latches for pool‑adjacent gates, and rip‑cut waste on custom heights ensures the estimate includes materials and labor that would otherwise appear as change orders, delivering a calculator output that becomes a solid baseline specification for multiple bids rather than a loose per‑foot average.

Common Scottsdale variables

Several variables regularly move Scottsdale wood fence costs: soil and rock conditions that affect post hole excavation time and concrete needs; sun exposure that accelerates finish wear and makes cedar or higher‑quality sealants cost‑effective over time; HOA guidelines that dictate height, visibility, and color, sometimes requiring cap‑and‑trim or decorative elements; and functional requirements like pet containment or pool adjacency that prompt tighter gaps, taller sections, or self‑closing, self‑latching gates, all of which should be toggled in the calculator to see their incremental impact before requesting quotes so the selected design, materials, and hardware match both compliance requirements and the planned budget without mid‑project revisions.

Cost factors to toggle

When configuring the wood fence cost calculator for Scottsdale projects, the most influential variables to toggle are height, wood species, post spacing, gate count/types, finish level, and site conditions, because each one compounds across total linear footage and directly drives both material quantities and labor hours; for example, moving from a 5‑foot semi‑privacy pine layout at 8‑foot post spacing to a 6‑foot full‑privacy cedar layout at 6‑foot spacing increases posts, rails, pickets, concrete volume, cutting waste, and installation time simultaneously, while adding a driveway gate layers in heavier posts, framed gate leaves, upgraded hinges, self‑closing latches for pool adjacency, and added bracing, so modeling these deltas in the calculator before requesting bids ensures the baseline design that goes to contractors is compliant, realistic for Maricopa County wind and soil realities, and less susceptible to budget‑busting change orders once work begins and inspections or HOA walkthroughs occur.

Maintenance and lifespan assumptions

To keep estimates honest over the fence’s service life, plug maintenance and lifespan assumptions into the calculator notes so the chosen wood species and finish plan match Scottsdale’s heat, UV, and pest pressures; cedar generally offers longer service life and better dimensional stability than pressure‑treated pine, especially under intense sun, but still benefits from periodic staining or sealing to maintain color and slow weathering, whereas pine is cheaper up front yet demands more aggressive maintenance to reduce warping, checking, and early decay, which means the “cheaper” option can converge in total cost once recurring finish work and board swaps are factored in, especially on long 6‑foot privacy runs exposed to full sun and irrigation overspray—so setting expectations for stain/seal cycles and potential board replacement intervals inside the planning stage helps prevent under‑budgeting and aligns the selected material with long‑term ownership goals for Scottsdale properties.

HOA and environmental considerations

Because many Scottsdale HOAs specify allowed fence materials, colors, and maximum heights, and front‑yard heights are often stricter than rear‑yard limits, it is prudent to model only HOA‑compliant scenarios in the calculator and include finish color or stain requirements so bids stay apples‑to‑apples; at the same time, local environmental risks such as subterranean termites, irrigation‑driven moisture near posts, and dense planting zones against fence lines should influence design and maintenance inputs, prompting the use of treated posts, proper post‑to‑soil detailing, and spacing vegetation off the fence to reduce hidden damage over time, which in turn preserves the calculator’s projected lifespan and reduces surprise repair costs that otherwise appear years three to five into ownership.

Estimating per‑foot pricing

When translating the calculator’s quantities into per‑foot pricing suitable for Scottsdale planning, anchor the model to a 6‑foot privacy baseline and then run deltas for species, spacing, gates, and finish, because national ranges compress regional realities and Scottsdale jobs often swing based on labor availability and site prep; recent 2025 cost snapshots for wood fencing indicate wide spans driven by material upgrades and complexity, so treating the per‑foot figure as an output of posts, rails, pickets, and concrete—rather than a generic input—yields a far more reliable benchmark to compare bids, especially when driveway gates, stepped panels on slopes, and cap‑and‑trim details are present in the spec the calculator exports for contractors to price. Cedar upgrades frequently lift per‑foot totals above basic pressure‑treated builds but can return that premium over time via better dimensional stability and reduced replacement frequency under intense sun, making it smart to run parallel calculator scenarios for cedar versus pine at the same height and spacing to surface the true cost curve per linear foot before committing to a purchase order or submitting for HOA review.

Gates, hardware, and add‑ons

Gates have outsized budget impact relative to their linear footage, so configure the calculator to treat each pedestrian and driveway gate as a mini‑assembly with dedicated posts, framed leaves, premium hinges, latches, and, where applicable, self‑closing, self‑latching hardware for pool‑adjacent sections to maintain code compliance and avoid post‑bid change orders; driveway gates often involve heavier posts, more robust frames, and alignment labor, which is why two otherwise identical 120‑foot runs can diverge hundreds of dollars depending on whether the layout includes a single pedestrian gate or a 12‑ to 14‑foot vehicle entry that also demands stronger bracing and deeper concrete embeds to handle weight and use cycles. Decorative upgrades such as cap‑and‑trim, horizontal layouts with tighter tolerances, integrated lattice toppers, or pre‑staining/sealing add materials, labor, and handling time that compound across the run, so toggling these features on and off inside the calculator clarifies their incremental impact and prevents “scope creep” during contractor conversations, ensuring all bids price the same feature set and helping Scottsdale homeowners decide which visual upgrades justify their cost per linear foot.

Permits, inspections, and timeline

Project timelines and soft costs can shift totals even when material counts are fixed, so incorporate Scottsdale’s permit expectations and any HOA architectural reviews into the planning assumptions the calculator exports, because a design that appears straightforward on paper may need additional documentation, minor height adjustments along front setbacks, or pool‑safety hardware confirmations that affect both schedule and line items; referencing local fence and wall guidance to verify thresholds for permit reviews and height/location constraints reduces redesign risk and aligns the estimate with what the city and HOA will actually approve on first pass. Where neighborhood CC&Rs require specific heights, finishes, or visibility standards, submitting the calculator’s bill of materials and annotated layout alongside the architectural application speeds approvals and keeps installer bids synchronized to an identical scope, avoiding the downstream cost of re‑mobilization or material returns if a non‑conforming detail is flagged during HOA walkthroughs or pre‑pour inspections.

Scottsdale-specific inputs

When dialing in a wood fence cost calculator for Scottsdale, configure inputs to reflect desert climate, soil, and exposure realities by setting deeper post embed assumptions for wind events, selecting concrete volumes that account for wider post holes in caliche or rocky soils, and choosing wood species and finishes that tolerate intense UV and heat, because these localizations prevent underestimating materials and labor and yield outputs that track more closely with what contractors will actually quote on 6‑foot privacy runs and gated layouts common to Maricopa County neighborhoods. HOA and city guidance frequently shape workable heights, front‑yard visibility, and pool‑adjacent hardware, so aligning calculator height, gate latch specifications, and any cap‑and‑trim details with Scottsdale walls and fences standards and typical HOA architectural rules reduces redesign risk and ensures the exported bill of materials can be submitted with confidence for approvals and accurate bids.

Pool safety and gate rules

Because many Scottsdale properties include pools, gate configurations should be modeled not just as aesthetic choices but as safety‑critical assemblies that satisfy pool barrier rules, which typically require self‑closing, self‑latching hardware at prescribed heights and swing directions, making it essential to toggle compliant hardware packages in the calculator so costs for upgraded hinges, latches, and stronger gate posts are captured up front rather than appearing as late‑stage change orders after plan review or inspection. Incorporating these requirements into the initial specification also influences layout decisions such as gate placement away from climbable features and ensures the per‑foot figure includes the labor time for precise alignment and testing, which helps prevent schedule slips at inspection and keeps the final invoice aligned with the pre‑bid estimate derived from the calculator’s detailed material and hardware line items.

HOA approvals and CC&Rs

Most Scottsdale HOAs maintain CC&Rs and architectural guidelines that prescribe allowable fence heights, materials, finishes, and sometimes color palettes, so building those constraints into calculator scenarios—setting maximum height for front setbacks, selecting approved wood species or finish tones, and indicating decorative elements like lattice or cap‑and‑trim only if permitted—creates a submission‑ready spec that accelerates architectural approval and avoids rework costs. Packaging the calculator’s bill of materials, elevation sketches, and a note citing compliance with HOA rules alongside the application helps standardize contractor bids to the same scope and reduces the risk of last‑minute changes if an architectural committee flags a non‑conforming detail during review or preconstruction walkthroughs.

Compare quotes effectively

When it’s time to turn the calculator output into contractor bids, insist that every quote mirrors the exact specification exported from the wood fence cost calculator—total linear footage by section, height, species, post size and spacing, rail count, picket width and gap, gate quantities and widths, concrete embed depth and bag count, hardware SKUs, finish/stain steps, and any cap‑and‑trim or lattice details—because this forces an apples‑to‑apples comparison where price differences actually reflect labor efficiency, scheduling, or craftsmanship rather than silent substitutions like thinner rails, fewer bags of concrete, or economy hardware that can shorten lifespan and inflate repairs; require line‑item breakdowns and explicitly reject lump‑sum quotes that omit materials detail, since those make it impossible to validate that bids match the calculator’s bill of materials and can hide scope gaps that later become change orders. A structured comparison also includes checking license/insurance proof, asking for a realistic start‑to‑finish timeline tied to material lead times and HOA approvals, and clarifying who handles permits and inspections, because “low” bids sometimes externalize soft costs or omit disposal, utility locates, or haul‑off, and a standardized scope document rooted in the calculator prevents those omissions from slipping through and distorting the true total cost of the Scottsdale fence project.

What to include in scope

A robust scope derived from the calculator should list quantities and standards for every major component—posts by size/spec and embed depth, rail count and dimensions, picket count by width and pattern, bagged concrete volumes per hole, gate frames and hardware sets, fastener type and coating, and finish steps—along with site prep and cleanup, utility locates, and haul‑off, because this detail not only keeps contractors aligned but also makes it simple to verify deliveries on site and to hold installers accountable to the promised specification; including tolerances for rail spans, maximum gap variance at grade, straightness, and gate clearances adds measurable quality targets that reduce disputes and rework after installation. Providing drawings or a simple marked plan with section lengths, slope notes, and gate swing directions alongside the calculator’s bill of materials further tightens alignment, ensuring the per‑foot totals in each bid are pricing the same geometry and assemblies rather than assumptions that diverge once crews start setting lines and digging posts.

Warranty and service terms

Before awarding the job, weigh the warranty terms alongside price by confirming workmanship coverage duration, response timelines, and any material system warranties such as “cedar post on pipe” guarantees, because a slightly higher bid that includes faster service and longer coverage can outperform the cheapest number over the fence’s lifespan; look for clear wording on what is and isn’t covered—natural wood checking, UV discoloration, soil movement, storm damage, and hardware adjustments—and prefer installers who publish workmanship warranties of at least one to three years with defined response windows and, where applicable, extended terms on reinforced post systems that mitigate rot and movement in hot, irrigated Scottsdale yards. Ask how warranty claims are processed and whether gate hardware, latches, and self‑closing mechanisms used for pool‑adjacent sections have distinct coverage, since those parts bear frequent use and must remain compliant; documented, responsive warranty support is a strong signal of a contractor that stands behind the spec produced by the calculator rather than cutting corners that save dollars on day one but cost far more in premature repairs and replacements.

Calculator outputs to export

After finalizing inputs, export the wood fence cost calculator outputs as a clean scope packet that includes a bill of materials by section, total linear footage, height, wood species, post size and spacing, rail counts, picket width and pattern, gate quantities and widths, concrete volumes per post, hardware SKUs, finish steps, and any decorative options like cap‑and‑trim or lattice, because this package becomes the single source of truth for Scottsdale installers to price against and prevents scope drift when bids come back with substitutions or omissions that would otherwise muddy comparisons and inflate costs later via change orders; attaching a simple annotated plan with section lengths, grade notes, gate swing directions, and pool‑adjacent hardware requirements ensures that every contractor is estimating the same geometry, assemblies, and compliance features that the calculator quantified, turning a theoretical estimate into a buildable, approvable specification suitable for HOA and city reviews. Including tolerances—maximum rail span, allowable picket gap variance, post plumb tolerance, gate clearance targets, and latch heights for pool safety—further translates calculator numbers into measurable quality standards, which reduces disputes during inspections and aligns per‑foot pricing with workmanship expectations rather than leaving execution details to interpretation that can undermine the long‑term value of the chosen wood species and finish system in Scottsdale’s climate.

Scheduling and lead times

Turn the calculator’s quantities into a realistic schedule by mapping material lead times for chosen wood species, hardware sets, and finish products, then layering HOA architectural review windows and Scottsdale permit checks so the projected start date reflects actual dependencies rather than optimistic assumptions that slip once paperwork begins; the same scope packet used to request bids should accompany HOA submissions so committees evaluate exactly what contractors will build, minimizing redesign loops that push installation into hotter months when crews and inspections book out faster and labor efficiency drops in high heat, which can indirectly raise costs even if material quantities remain identical to the calculator’s output. Confirm inspection points for pool‑adjacent gates and any height or setback confirmations early and block calendar time for these checkpoints, because missed or failed inspections can cause re‑mobilization and additional labor that the calculator did not assume, and ensuring the city’s walls and fences guidance is reflected in the plan keeps the schedule and budget aligned with what Scottsdale will approve on first pass.

Pre‑construction checklist

Before breaking ground, convert the calculator and scope packet into a field checklist that verifies property line locations, underground utility locates, gate swings and clearances, material delivery counts versus the bill of materials, and site prep such as vegetation clearance and grading for straight lines, because catching discrepancies at this stage prevents on‑the‑fly changes that invalidate the calculator’s assumptions about post spacing, concrete volumes, or gate framing; have the installer mark post centers and gate openings on the ground against the plan and confirm any stepped or racked panel decisions on sloped sections so cut plans and waste factors match reality rather than inflating after layout, which protects the per‑foot cost derived from the calculator by preventing unplanned labor and material adders during installation. For properties with pools or HOA visibility constraints, walk hardware placement, latch heights, and any front‑yard height transitions with the crew lead before digging, aligning field execution with the compliance and safety factors already priced into the calculator so inspections and approvals proceed smoothly without last‑minute redesigns that could otherwise extend timelines and increase total cost.

Post depth and concrete

For Scottsdale planning, configure the wood fence cost calculator to assume conservative post embed depths and concrete volumes, since deeper sets improve wind resistance and reduce leaning on taller 6‑foot privacy runs; common guidance recommends burying roughly one‑third of post height with concrete backfill, translating to about 2 to 3 feet of embed for typical residential fences, while also accounting for wider holes in rocky or caliche soils that consume more mix, so modeling 6×6 corner and gate posts with higher concrete volumes and verifying hole diameters in the calculator will better match real consumption on Maricopa County sites exposed to monsoon gusts and hardpan digging conditions. Converting cylindrical hole dimensions into cubic feet with the calculator improves accuracy—volume V=πr2hV=πr2h in feet—so a 10‑inch diameter by 30‑inch deep hole approximates 1.36 cubic feet before subtracting post displacement, and scaling this across 20–30 posts shows why per‑foot totals move noticeably when embed depth increases a few inches or diameters step up to stabilize gates and corners in high‑wind exposures common around Scottsdale.

Staining and UV protection

Because intense desert UV degrades unprotected boards quickly, bake stain/seal cycles into the calculator notes so lifecycle costs are realistic: pigmented stains with UV inhibitors protect far better than clear water repellents, initial staining often performs best after new lumber has acclimated for several weeks so moisture can escape, and re‑stain intervals tend to be shorter under harsh sun—think roughly every 2–3 years versus longer cycles in milder climates—so the “cheaper today” choice can converge in total cost once recurring finish work is priced into the plan for south‑ and west‑facing Scottsdale runs. Including product type, color, and application steps in the scope packet keeps bids apples‑to‑apples, reduces blotchy results from premature application on wet lumber, and preserves the calculator’s projected lifespan by aligning maintenance with the climate realities that otherwise gray, check, and embrittle pickets ahead of schedule.

Utility locates before digging

Before any post holes are dug, incorporate utility locate timing into the schedule derived from the calculator, since Arizona law and best practice require calling 811 to mark public utilities and, where needed, hiring a private locator to identify homeowner‑owned lines like irrigation or low‑voltage runs that won’t be marked by the public service; building a 2–3 business day buffer for locates prevents last‑minute rescheduling, avoids dangerous strikes, and ensures post placements match the plan rather than shifting on the fly to dodge unmarked lines, which would otherwise invalidate the calculator’s spacing, concrete volumes, and gate locations. Crews should maintain clearance from marked utilities as instructed and adjust hole positions only after the scope owner updates the layout, preserving alignment with the calculator’s quantities and keeping the fence straight and compliant without incurring re‑mobilization or waste beyond what the estimate anticipated.

Estimated Scottsdale costs

| Feature/Cost Category | Professional Installation | DIY Installation |

|---|---|---|

| Average Material Cost (per linear foot) | $25 - $60 (premium options available) | $18 - $50 (selection limited to retail options) |

| Average Labor Cost (per linear foot) | $20 - $40 (includes site prep & finishing) | $0 (homeowner supplies all labor) |

| Permitting and Inspection | Included and managed by contractor | Homeowner responsibility; fees vary |

| Project Timeline | 1–2 days (for typical yards) | Several days to weeks (owner availability dependent) |

| Warranties/Support | Labor and material warranty included | No warranty (unless material-specific) |

| Access to Custom Options | Extensive: automation, colors, designs | Limited; advanced options require extra skills/tools |

| Maintenance Packages | Available as add-ons | All maintenance homeowner’s responsibility |

| Total Cost Estimate (per linear foot) | $45 - $100+ | $18 - $70 (may increase with unexpected issues) |

For Scottsdale budgeting, a practical way to transform the wood fence cost calculator’s quantities into per‑foot numbers is to anchor a 6‑foot privacy baseline and then layer premiums or reductions for species, spacing, gates, and finish, because 2025 data shows wood fence material ranges commonly spanning from the high teens to around $60 per linear foot at retail or pro supply depending on species and profile, while labor often runs in the $20–$40 per‑foot band for straightforward lots, with totals climbing for multiple gates, rocky soils, deeper embeds, and decorative details such as cap‑and‑trim that add cuts and handling time, which is why treating per‑foot as an output of posts, rails, pickets, and concrete from the calculator—rather than a generic input—yields the most reliable Scottsdale benchmark before bids are requested. Cedar upgrades typically push into the higher material tier compared with pressure‑treated pine, but better dimensional stability and slower degradation under intense UV can narrow lifecycle cost differences when recurring staining and early board replacement on budget builds are factored in, so creating parallel calculator scenarios for pine versus cedar at identical height and spacing gives a clear side‑by‑side that reflects actual 2025 material and labor conditions rather than national averages that compress local variability in Maricopa County. Pool‑adjacent sections and driveway gates also require modeling as distinct assemblies in the calculator because compliant self‑closing, self‑latching hardware, stronger posts, deeper concrete, and alignment time can add noticeable dollars per foot in the affected segments, and folding those assemblies into the per‑foot roll‑up prevents surprises once inspections and hardware specs are confirmed for Scottsdale jobs.

What influences the high/low range

The spread between low and high per‑foot estimates is driven primarily by height, species, post spacing, gate count and width, and finish system, and secondarily by site realities like caliche or rocky soils that increase digging time and concrete consumption, plus slope conditions that force stepping or racking and add labor for layout and cuts, which is why two fences of identical length can price very differently once the calculator toggles are changed to reflect a premium cedar 6‑foot privacy with closer post spacing and cap‑and‑trim versus an economy pine semi‑privacy at wider spacing without decorative elements. Published 2025 snapshots for cedar and wood privacy builds continue to confirm wide national ranges that broaden further once upgraded hardware, pre‑stain, and gate assemblies are included, so it is best practice to treat the calculator’s per‑foot outputs as a living baseline and export them as a scope packet for apples‑to‑apples bidding rather than relying on a single “average” that won’t survive contact with Scottsdale’s labor rates, sun exposure realities, and HOA compliance requirements.

Turning the estimate into a bid

Once an internal estimate is set, export the calculator’s bill of materials and assumptions—linear footage by section, height, species, post size and spacing, rail count, picket width/pattern, gate assemblies and hardware SKUs, concrete per hole, finish steps, and any cap‑and‑trim or lattice—to standardize contractor quotes and ensure per‑foot numbers are pricing the same specification, because missing details often lead to silent substitutions like thinner rails or fewer concrete bags that appear cheap up front but reduce lifespan and inflate long‑term maintenance in Scottsdale’s heat and monsoon winds. Pair this scope with HOA documentation and Scottsdale walls/fences guidance for heights and locations so bidders price an approvable design, and include notes for pool‑adjacent hardware where required, which tightens timelines by reducing redesign loops and aligns final invoices with the calculator’s line‑item logic instead of generic per‑foot allowances that can mask scope gaps until inspection or installation day.

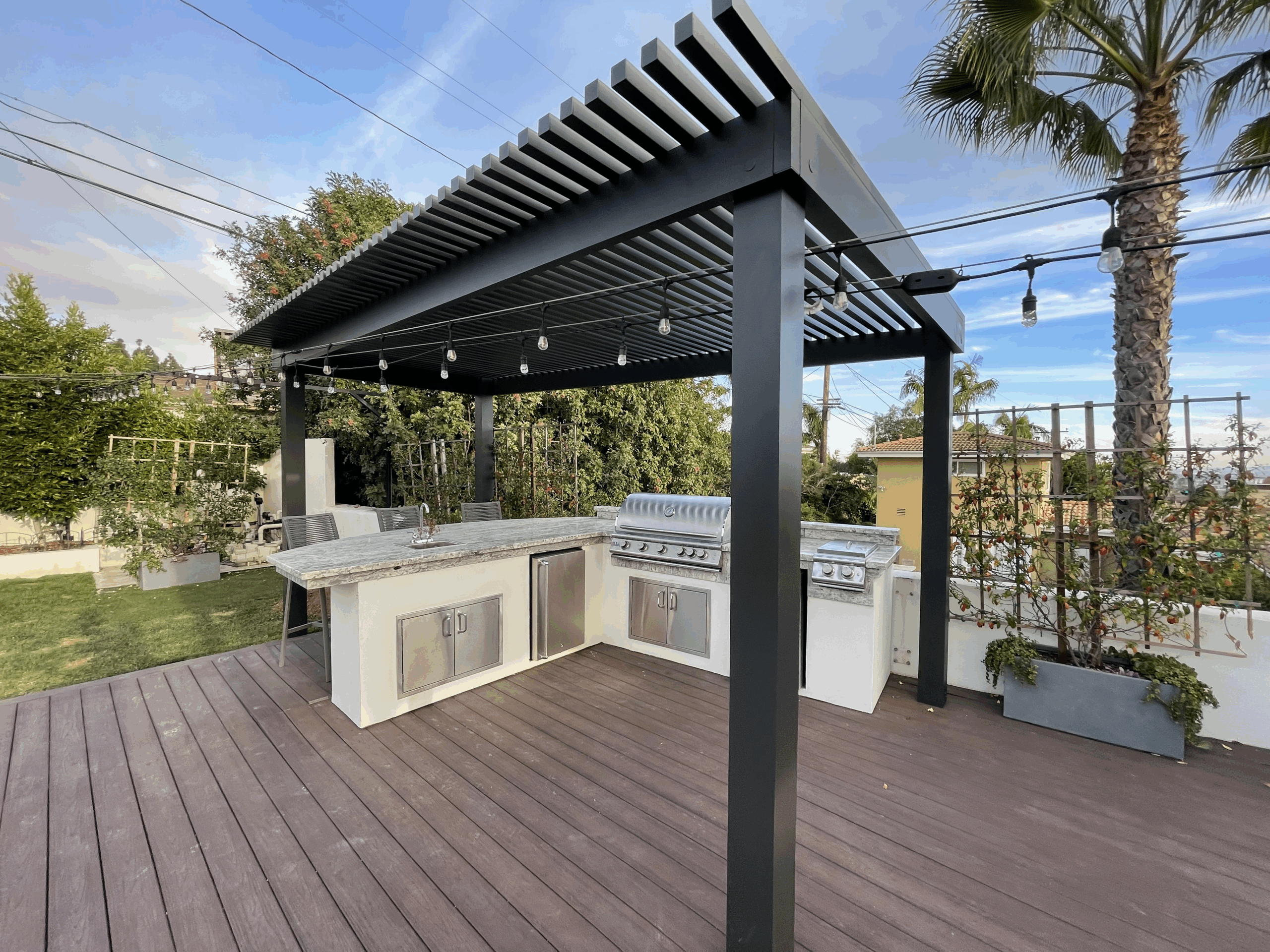

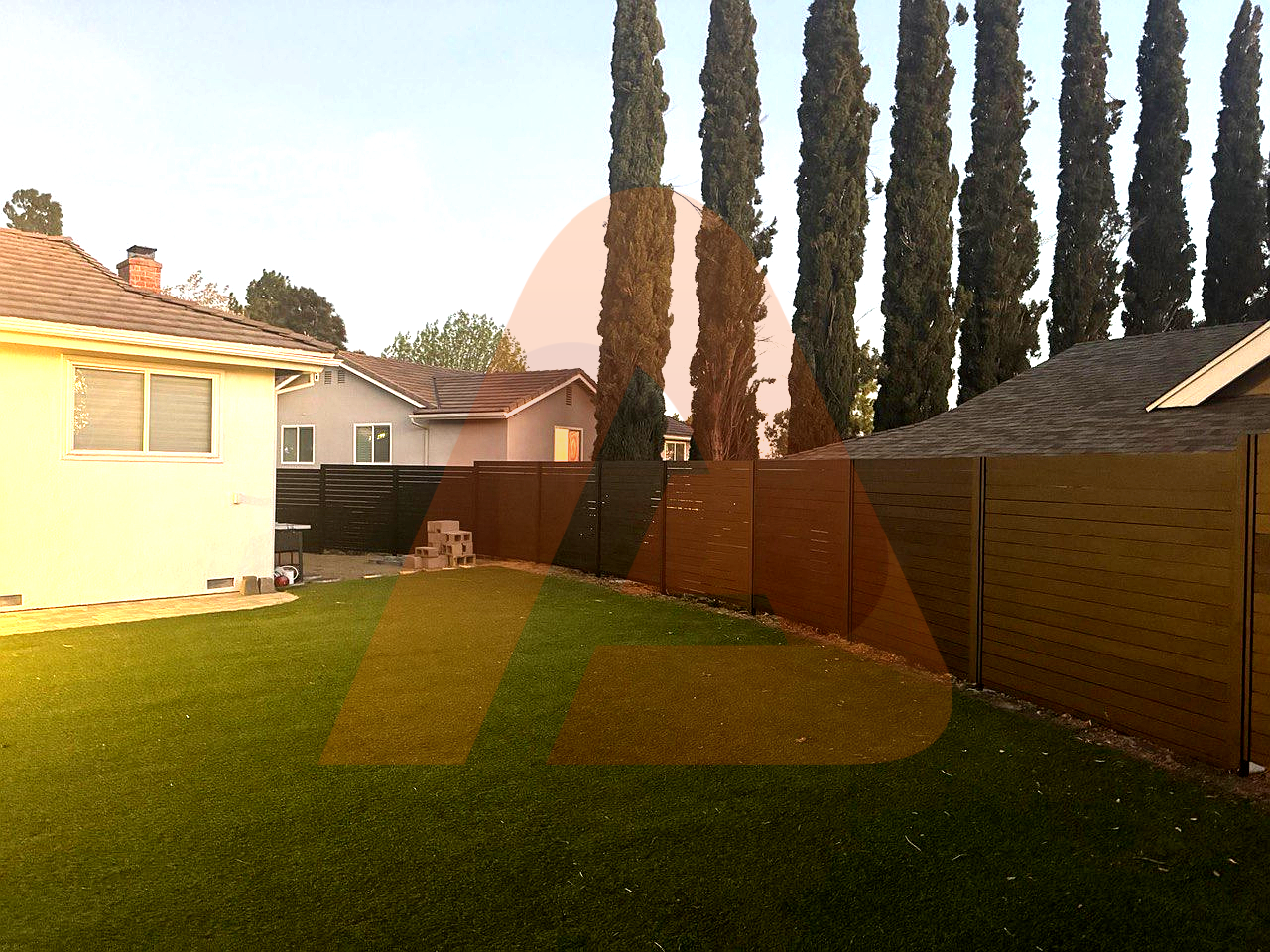

Design Your Ideal Fence & Gates Today!

Bring your vision to life with premium aluminum fencing, custom gates, and modern cladding solutions crafted to elevate any property.

Schedule A ConsultationBudget and financing options

Translating the wood fence cost calculator’s estimate into a cash‑flow plan can include contractor financing, personal loans, or home‑equity options, and many fence companies or third‑party platforms now offer same‑day qualification with fixed‑rate installment terms, which helps align a 6‑foot privacy build with monthly budget targets while preserving emergency savings and accounting for seasonal price swings in materials and labor common in busy Scottsdale months; national 2025 home‑improvement guidance also notes that some contractors partner with lenders for integrated financing, so exporting the calculator’s scope to financing applications yields cleaner approvals and prevents scope changes later that would otherwise alter the funded amount and require amendments. Local providers and online marketplaces serving Scottsdale advertise multiple plan types—from short‑term, higher‑payment structures to longer‑term, lower‑payment options—so comparing APR, fees, and prepayment terms against the calculator’s total is key, and aligning the funded amount with a 10–15% contingency for rocky soils, deeper embeds, or gate upgrades reduces the risk of running short mid‑project when inspections or HOA adjustments add cost.

Cost‑saving strategies that keep quality

There are pragmatic ways to reduce the calculator’s total without compromising durability: time purchases for off‑season discounts, consolidate orders to unlock bulk pricing tiers, rent specialty tools rather than buying, and standardize hardware SKUs to avoid expensive one‑off items, because suppliers often run late‑fall and winter promotions and end‑of‑year closeouts that lower unit costs, and group buys with neighbors can meet discount thresholds even for single‑yard projects; in addition, repairing or re‑framing sound sections rather than full replacement can stretch budgets when posts or rails remain serviceable, and buying direct from wholesalers or pro desks can beat big‑box retail when the calculator shows higher volumes of posts, rails, and pickets on long runs. Before switching species to save money, validate lifecycle costs against Scottsdale UV exposure—cheaper materials can demand more frequent staining and early board swaps—so the “savings” do not evaporate over the first few years, and keep a running comparison inside the calculator scenarios to confirm the lowest total cost of ownership rather than the lowest day‑one number.

Disposal and city services

Plan disposal and haul‑off inside the calculator’s estimate and schedule, using Scottsdale’s brush and bulk collection where appropriate and confirming city trash and recycling guidelines if staging debris on‑site between phases, because monthly brush/bulk pickups and city collection rules can offset hauling costs when timing cooperates, and ensuring container limits and placement rules are followed avoids missed pickups that disrupt the installation schedule and add labor for re‑handling materials. For recyclable materials or special handling, Scottsdale’s recycling resources and guides help determine proper channels so crews aren’t turned away at facilities, and embedding these logistics into the scope packet keeps contractor bids aligned with the same disposal method and costs rather than leaving a soft‑cost gap that appears after demo day.

Permits and compliance

When finalizing a wood fence cost calculator scenario for Scottsdale, build in compliance guardrails that reflect how reviews actually work: assume courtesy site plan review for low-height segments and formal permits for taller sections, verify that any fence exceeding low thresholds will trigger building safety review, and include notes in the scope packet that the design respects setbacks, easements, drainage, and front‑yard visibility limits so the submission passes on first review without redesigns that would otherwise add days and cost to the plan; by aligning the calculator’s height, location, and gate details with city guidance before requesting bids, the final per‑foot number reflects an approvable design rather than a theoretical layout that runs afoul of thresholds once routed through the city’s “One Stop Shop” and related review queues, which keeps installer timelines and material orders synchronized with a permit that will actually be issued.

Height and front‑yard constraints

Because Scottsdale typically allows taller fences along side and rear yards than in front setbacks, treat front‑facing runs as a distinct section in the calculator with separate height, material, and visibility assumptions so the exported bill of materials and drawings show compliant transitions at the setback line, rather than a uniform height that later requires field cuts and rework; modeling these segments separately also lets the estimator measure how cap‑and‑trim, lattice toppers, or decorative gates interact with visibility rules and height caps, especially near driveways and corners, and prevents over‑ordering pickets or rails that would be trimmed down or rejected during review, preserving the accuracy of per‑foot totals and avoiding scope creep during inspections or HOA walkthroughs.

Pool and inspection checkpoints

For any property with a pool or planned pool, split the calculator into pool‑adjacent assemblies with compliant gate hardware and latch placement assumptions, outward‑swing gates, and minimum barrier heights, so that the scope packet explicitly calls out these details for inspection scheduling and pass‑first‑time execution; bundling inspection milestones into the schedule—such as pre‑pour checks for post holes in sensitive areas and final gate operation checks—keeps the project from stalling at the finish line, ensures that the labor embedded in the per‑foot estimate covers alignment and adjustment time, and eliminates last‑minute hardware changes that would otherwise throw off both cost and completion dates once inspectors verify latch height and self‑closing performance.

Installation timeline overview

For planning based on a wood fence cost calculator, a realistic Scottsdale installation timeline begins with scope finalization and ordering, then moves through HOA/permit steps, mobilization, and build, with most straightforward 6‑foot privacy projects landing in a two‑to‑four‑week window from approval to completion depending on lead times, crew availability, and site complexity; in practice, expect 3–7 days for HOA/permit processing once the calculator’s scope packet and drawings are ready, 3–10 days for materials staging if using in‑stock species and standard hardware, and 1–3 active workdays on site for 120–180 linear feet with one pedestrian gate, allowing additional days for driveway gates, rocky digs in caliche, deeper post embeds for wind exposure, and finishing or pre‑stain steps that need curing time, so the calendar reflects not just the hands‑on hours but also the coordination milestones that keep the build aligned with the estimate and inspection checkpoints.

Pre‑build milestones

Before crews arrive, aligning the calculator’s bill of materials with reality saves days later: confirm utility locates are scheduled and marked, verify HOA approvals match the submitted heights, materials, and gate hardware, and lock delivery windows with the supplier so posts, rails, pickets, concrete, and hardware arrive before ground is broken; this is also the moment to walk the property with the layout plan in hand and validate section lengths, gate swings, and any stepped versus racked treatment for slopes, because catching a 4–6 inch delta in grade or a shifted gate position at this stage prevents rework that would otherwise ripple through post spacing, concrete volumes, and cut lists, extending the on‑site schedule and inflating labor beyond what the calculator anticipated.

On‑site execution cadence

Once mobilized, efficient Scottsdale installs follow a tight cadence that mirrors calculator assumptions: string lines and mark centers, dig and set posts with conservative embeds and proper concrete volumes, verify plumb and alignment, then stage rails and pickets for rapid fastening while holding tolerances for gaps, grade follow, and straightness that were defined in the scope; gates are framed and hung after adjacent spans are stable, with pool‑adjacent hardware aligned to compliance heights and self‑closing performance, and finishing tasks—cap‑and‑trim, touch‑sanding, staining or sealing—close out the build with a final walkthrough that checks operation, clearances, and fastener patterns against the quality targets, ensuring the calendar time and costs stay consistent with the pre‑bid plan rather than drifting from unplanned field adjustments or missed inspection details.

Maintenance planning

A wood fence cost calculator becomes more valuable when paired with a maintenance plan that reflects Scottsdale’s UV, heat, and irrigation realities, so factor in a schedule for semiannual inspections, gentle washdowns to remove dust and algae, targeted board or fastener replacements, and stain/seal cycles that keep UV and moisture at bay; building these expectations into the estimate prevents “surprise” ownership costs, preserves straightness and gate performance, and extends the life of pine or cedar under desert sun, especially along south‑ and west‑facing runs where color fade and checking appear first.

Inspection and cleaning cadence

Set a spring and fall inspection rhythm that checks post plumb, rail fasteners, picket gaps, grade contact, and gate hardware tension, then pair it with a cleaning pass that uses low‑pressure rinsing and mild detergents rather than aggressive blasting, because high pressure can etch fibers and invite faster water intrusion; clearing soil and mulch away from picket bottoms, re‑tightening hardware, and spot‑sealing fresh cuts or exposed end grain all reduce premature rot and warping, keeping the fence aligned with the performance and lifespan assumptions used in the calculator’s long‑term budgeting.

Stain, seal, and small repairs

In Scottsdale’s climate, plan for pigmented stains with UV inhibitors on roughly 2–3 year cycles, allowing full dry time after cleaning before application and focusing on sun‑blasted sections first if phasing is needed to match cash flow; replace or re‑set any loose or compromised posts before finish work so movement doesn’t crack fresh coatings, and standardize fasteners and hinge/latch SKUs across gates to simplify future tune‑ups, which keeps annual maintenance predictable and ensures the total cost of ownership stays close to the wood fence calculator’s lifecycle projections.

Design Your Ideal Fence & Gates Today!

Bring your vision to life with premium aluminum fencing, custom gates, and modern cladding solutions crafted to elevate any property.

Schedule A ConsultationFinal walkthrough checklist

Before closing out the project, convert the wood fence cost calculator’s scope into a punch‑list walkthrough that verifies every measurable detail on site, including post plumbness within tolerance, straight string‑line alignment, consistent rail heights, uniform picket gaps, proper grade follow without soil contact that traps moisture, and clean cap‑and‑trim terminations, because catching minor deviations at this stage prevents long‑term issues like gate sag, premature board rot, and wandering lines that become noticeable from the street; pair this inspection with a count‑by‑item reconciliation against the bill of materials to ensure all SKUs specified—fasteners, hinges, latches, self‑closing mechanisms for pool‑adjacent gates, and stain or sealant—were installed as planned, and have the crew perform final adjustments so latch heights, gate swings, and clearances meet the scope’s compliance notes and the homeowner’s day‑to‑day usability expectations without requiring a return visit.

Documentation handoff

A strong close‑out includes handing off a simple packet that mirrors the calculator’s assumptions—final linear footage by section, post spacing, gate locations and hardware specs, concrete embed depths, wood species and grade, and finish product details with color and batch numbers—alongside any inspection sign‑offs, photos of key compliance items (like pool‑gate latch height and outward swing), warranty certificates, and care instructions, because this documentation supports future maintenance, streamlines any warranty claims, and gives a clear baseline if repairs or extensions are needed years later; include a maintenance calendar outlining cleaning, inspection, and re‑stain targets so the total cost of ownership stays aligned with the original estimate, and record any field adjustments from the plan (for example, an extra post added at a slope break) so future work and budgeting can account for the as‑built reality with no guesswork.

Next steps and maintenance cadence

With installation complete and the documentation in hand, schedule the first post‑installation check after one season to re‑tighten fasteners, verify gate alignment after initial wood movement, and touch up stain or sealant on exposed cuts, because small tune‑ups early prevent compounding issues that inflate lifecycle costs; align the ongoing maintenance rhythms with the calculator’s projections—semiannual inspections, gentle washdowns, hardware checks, and a 2–3 year stain cycle in Scottsdale sun—so the fence’s performance and appearance track the plan, and set calendar reminders tied to seasons to ensure tasks aren’t deferred during peak heat, keeping the system sound, compliant, and within the budget envelope envisioned when the wood fence cost calculator was first configured.

Common Mistakes to Avoid in Privacy Fence Installation

When wrapping up a wood fence project specified with a cost calculator, it’s smart to align expectations around workmanship and material warranties by confirming coverage terms in writing—typical workmanship coverage runs about one year with some contractors extending multi‑year terms, while materials are usually covered by the manufacturer with exclusions for natural wood behavior like checking, warping, shrinkage, and color change—so recording product SKUs, finish brands, batch numbers, and installation dates in the close‑out packet ensures clear proof for any future claim and keeps service responses fast by eliminating guesswork over what was installed and when.

What’s usually covered

Most workmanship warranties focus on defects in installation rather than wear from weather or use, which means items like post movement from initial settling, early gate sag due to hinge adjustment, or misaligned latches are commonly addressed during the term, while storm damage, irrigation‑driven rot, and impacts are excluded; manufacturers generally back material defects, not environmental aging, so a proactive maintenance cadence of inspections, re‑fastening, touch‑sealing cut ends, and periodic stain cycles helps keep the fence performing within the assumptions that underpinned the calculator’s lifecycle estimate and reduces the likelihood of issues that fall outside warranty scope.

How to document and claim

To streamline any future claim, keep a simple dossier tied to the calculator’s scope: the final bill of materials with quantities, photos of post embeds before backfill, hardware model numbers for gates (especially self‑closing and self‑latching sets near pools), finish specs with color and batch, and pass/fail notes from inspections; if a defect is suspected, capture dated photos, describe the symptom, and contact the installer promptly within the stated window, since many policies require timely notice, and be prepared for the contractor to assess whether the condition is installation‑related, material‑related, or maintenance‑related before authorizing repair or replacement.

Long-term durability planning

Building a long-term durability plan into the wood fence cost calculator assumptions helps Scottsdale projects stay on budget over the life of the fence by accounting for desert UV exposure, monsoon winds, and irrigation moisture from day one, which means estimating realistic stain/seal cycles, allocating small annual budgets for fastener retightening and hardware tune-ups, and planning mid-life board replacements on sun-blasted runs so the total cost of ownership aligns with expectations rather than spiking later from deferred maintenance that accelerates checking, warping, and color loss in pine or cedar under intense heat; pairing these lifecycle allowances with smart design choices such as raised picket bottoms to avoid soil contact, post caps to shed water, and standardized hardware SKUs for gates reduces premature failures, makes in-field repairs faster, and keeps the as-built system performing like the calculator projected even as seasons stress the structure year after year.

Climate-adapted finish strategy

For finishes, a climate-adapted strategy is crucial in Scottsdale: plan pigmented UV-inhibiting stains instead of clear repellents, schedule cleaning and prep during milder shoulder seasons, and apply coats with full drying windows so the film cures properly in low humidity, because rushing application in peak heat or on high-moisture lumber causes blotching and premature failure that shortens intervals and inflates lifecycle costs; segmenting the property by exposure (south and west faces first), noting product brand and batch in the closeout packet, and setting calendar reminders for 2–3 year re-coats keeps aesthetics and protection consistent, minimizes color drift between sections, and ensures the maintenance rhythm anticipated in the calculator actually happens on time.

Repair readiness and spare materials

Finally, establish repair readiness by storing a labeled micro-inventory of spare pickets, rails, post caps, hinges, and latches that match the installed SKUs, along with leftover stain for spot work, because small, prompt fixes after storms or heavy use prevent localized issues from spreading and eliminate mismatched components that can void workmanship or hardware support; keeping a simple log tied to the calculator’s original scope—recording each repair, replacement count, and finish touch-up date—creates a service history that preserves resale value, streamlines future warranty conversations, and feeds better assumptions back into any future calculator scenarios for expansions or replacements on the same Scottsdale property.

Seasonal upkeep schedule

A Scottsdale‑specific seasonal upkeep schedule translates the wood fence cost calculator’s lifecycle assumptions into actionable tasks by quarter, ensuring the fence stays aligned with performance and longevity targets despite desert UV, monsoon winds, and irrigation moisture; in spring, plan a deep inspection for post plumb, rail alignment, picket gaps, and gate hardware tension, followed by a low‑pressure wash to clear dust, pollen, and algae, then spot‑seal any fresh cuts or exposed end grain and tighten fasteners so thermal expansion through summer doesn’t loosen assemblies, while also trimming vegetation back from fence lines to keep airflow around boards and prevent trapped moisture that accelerates decay in shaded areas near irrigation heads. In summer, focus on UV defense and fasteners: check for early checking or color fade on south‑ and west‑facing runs, schedule stain touch‑ups where finish has thinned, lubricate hinges and latches that see heavy use, and verify that grade‑level clearances remain open after any landscape growth so airflow continues beneath picket bottoms, because slight seasonal movement is normal and proactive tune‑ups prevent gate sag or latch misalignment that otherwise compounds into larger repairs later in the year. Autumn is the time to prepare for wind and rain by re‑checking post plumb and gate alignment after monsoon gusts, clearing leaf buildup and debris that hold moisture against wood surfaces, verifying cap‑and‑trim integrity so water sheds properly, and planning any section‑by‑section re‑staining during cooler shoulder months when drying windows are reliable, which preserves finish performance into winter; then, in winter, maintain cleanliness and hardware function by gently rinsing dust and grit, keeping leaves and soil away from post bases, inspecting for any movement after storms, and documenting small issues to address promptly, ensuring the maintenance rhythm stays in sync with the lifecycle budget laid out when the calculator established total cost of ownership.

Final Thoughts

Choosing a wood fence cost calculator tailored to Scottsdale is the fastest way to turn design ideas into an accurate, approvable budget that reflects local rules, climate, and real unit pricing, so the final scope that goes to installers matches what will pass HOA and city reviews without costly redesigns or surprise adders at inspection time. By exporting a detailed bill of materials, modeling gates and pool‑adjacent assemblies as separate line items, and aligning post depth, concrete volumes, and finish cycles with desert conditions, the pre‑bid estimate becomes a dependable baseline that contractors can price apples‑to‑apples, keeping timelines, costs, and quality aligned from first measurement to final walkthrough. Building in maintenance assumptions—cleaning cadence, stain intervals, hardware tune‑ups—keeps total cost of ownership predictable under Scottsdale sun and monsoon winds, preserving aesthetics and function well beyond year one and validating the calculator’s lifecycle projections.

Design Your Ideal Fence & Gates Today!

Bring your vision to life with premium aluminum fencing, custom gates, and modern cladding solutions crafted to elevate any property.

Schedule A ConsultationFrequently Asked Questions

A practical 2025 range combines materials typically in the high‑teens to roughly $60 per linear foot depending on species/profile with labor around $20–$40 per foot for straightforward sites, with totals rising for gates, rocky digs, deeper embeds, and decorative details; treat per‑foot as an output of posts, rails, pickets, and concrete from the calculator, not a fixed input.

Yes, pool barrier rules require self‑closing, self‑latching hardware at prescribed heights and configurations, so model compliant gate assemblies in the calculator and carry those SKUs into the scope packet to avoid post‑bid changes and to pass inspection on the first attempt.

Scottsdale guidance and common HOA rules often allow taller fences in side and rear yards while restricting height and visibility in front setbacks, so split front runs into separate calculator sections with compliant heights and details to avoid redesigns during review.

Conservative practice is to increase embed depth and concrete volume—often targeting roughly one‑third of post length below grade and larger hole diameters for corners and gates—to boost resistance against monsoon gusts; calculate hole volume and concrete needs in the estimator so totals reflect field reality.

Plan pigmented, UV‑inhibiting stains on roughly 2–3 year cycles in desert sun, allowing proper prep and drying windows; documenting product type and intervals in the scope helps maintain appearance and longevity consistent with the calculator’s lifecycle budgeting.